Preparation method of catalytic cracking fuel gas sulfur transfer additive active component

An active component, catalytic cracking technology, applied in the field of flue gas desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

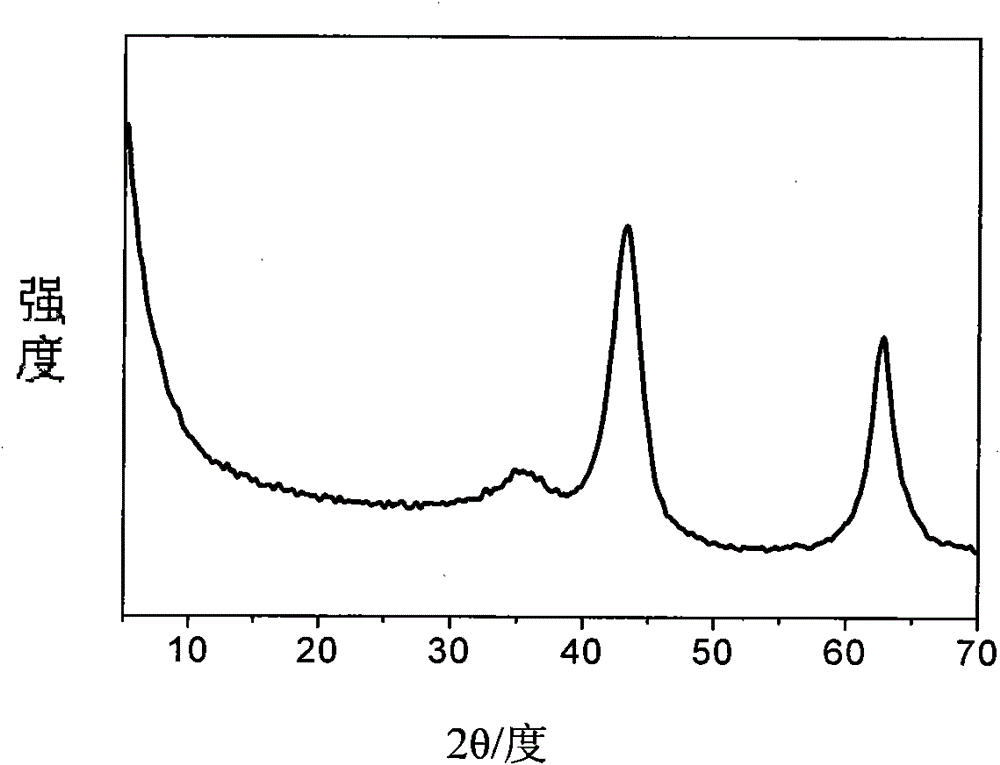

[0023] 1. Calcining magnesium aluminum hydrotalcite with a magnesium aluminum molar ratio of 3 at 450°C for 3 hours;

[0024] 2. Weigh 3g of the roasted product in step 1, dissolve it in 30ml deionized water to make a slurry, add 0.66g Ce(NO 3 ) 3 ·6H 2 O, heated to 100°C under stirring, kept at a constant temperature for 2 hours, filtered and washed until the pH value was neutral, and then dried to obtain the hydrotalcite-like precursor of the active component of the catalytic cracking flue gas sulfur transfer agent;

[0025] 3. After roasting at 800°C for 2 hours, the active component of catalytic cracking flue gas sulfur transfer agent can be obtained.

Embodiment 2

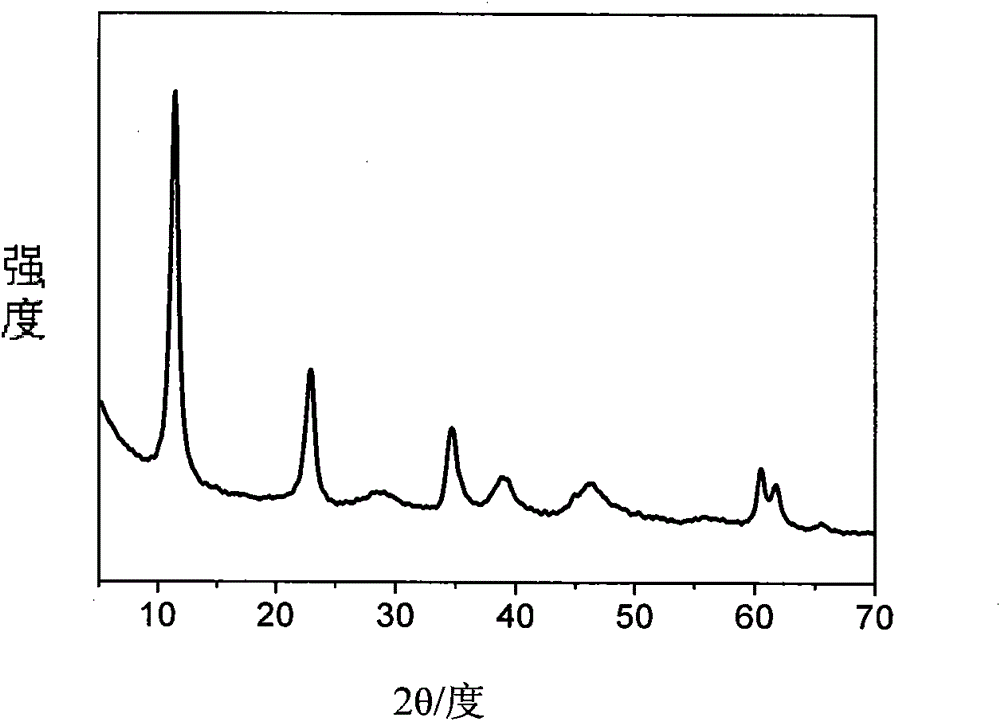

[0027] 1. Calcining magnesium aluminum hydrotalcite with a magnesium aluminum molar ratio of 2.2 at 450°C for 3 hours;

[0028] 2. Weigh 3g of the roasted product in step 1, dissolve it in 50ml of deionized water to make a slurry, add 0.66g of Ce(NO 3 ) 3 ·6H 2 O, heated to 100°C under stirring, kept at a constant temperature for 2 hours, filtered and washed until the pH value was neutral, and then dried to obtain the hydrotalcite-like precursor of the active component of the catalytic cracking flue gas sulfur transfer agent;

[0029] 3. Roast at 800°C for 2 hours to obtain the active component of catalytic cracking flue gas sulfur transfer agent.

Embodiment 3

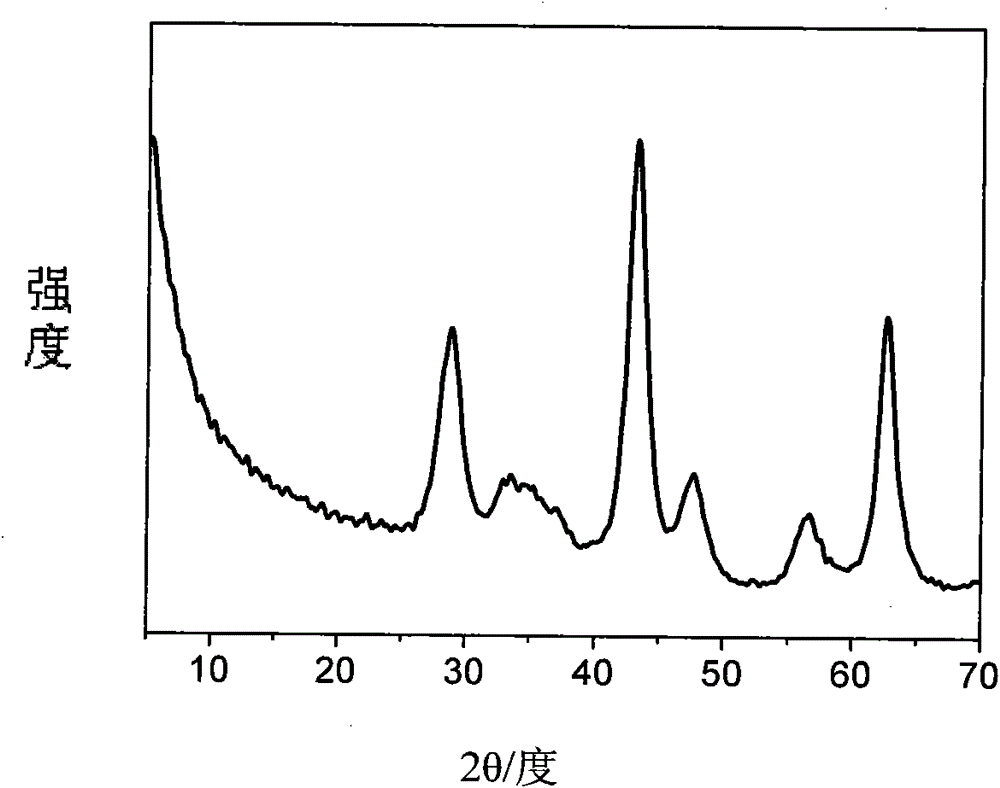

[0031] 1. Calcining magnesium aluminum hydrotalcite with a magnesium aluminum molar ratio of 4 at 450°C for 3 hours;

[0032]2. Weigh 3g of the roasted product in step 1, dissolve it in 30ml deionized water to make a slurry, add 0.66g Ce(NO 3 ) 3 ·6H 2 O, heated to 100°C under stirring, kept at a constant temperature for 2 hours, filtered and washed until the pH value was neutral, and then dried to obtain the hydrotalcite-like precursor of the active component of the catalytic cracking flue gas sulfur transfer agent;

[0033] 3. Roast at 800°C for 2 hours to obtain the active component of catalytic cracking flue gas sulfur transfer agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com