Small-sized H-shaped steel online shearing device

A shearing device, H-beam technology, applied in shearing devices, cutters for shearing devices, shearing equipment, etc., to achieve the effects of accelerating shearing speed, short action time, and strong braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention is described below.

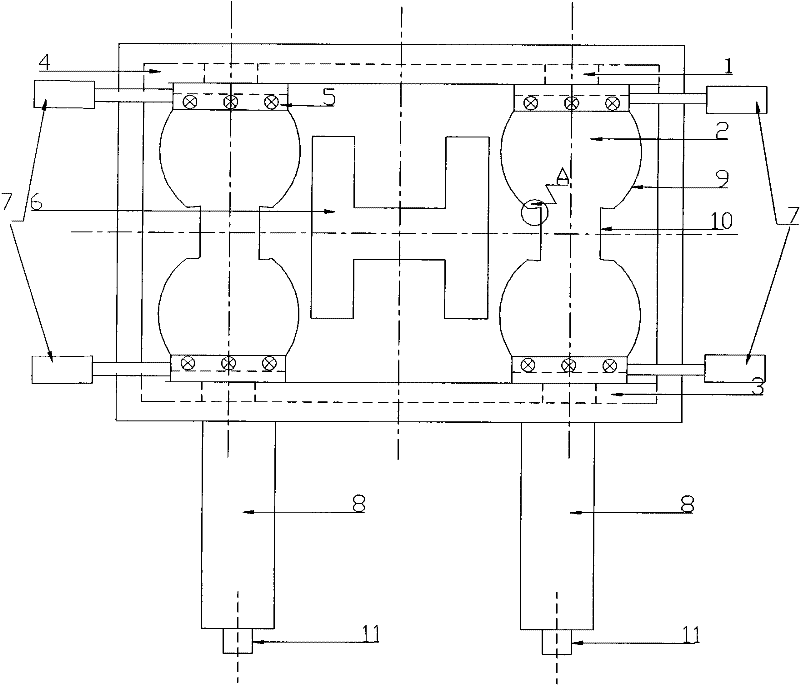

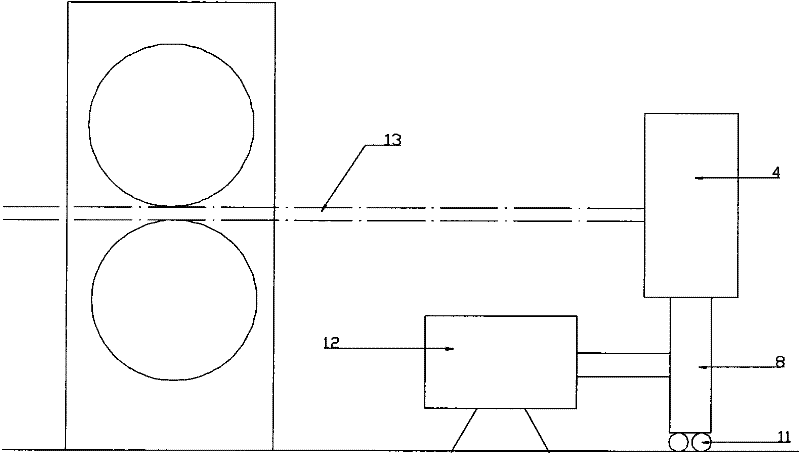

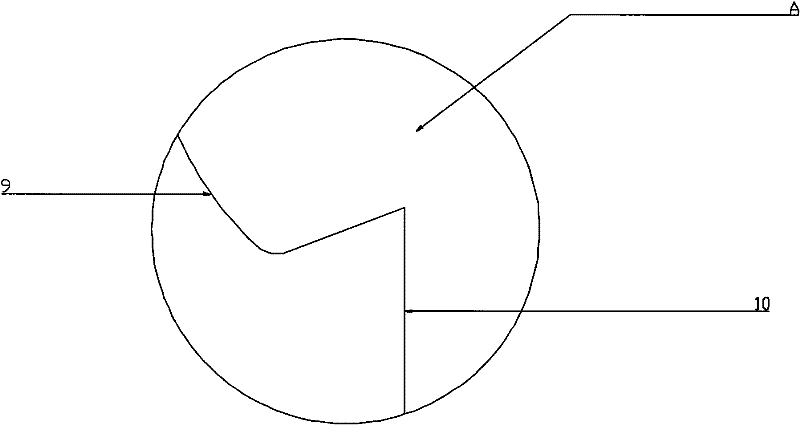

[0023] Such as figure 1 The shown small-sized H-shaped steel online shearing device includes a frame 4, a guide block 1 and two left and right double-sided cutters 2. The left and right edges of the double-sided blade 2 are symmetrical in structure, and the shape of the blade is a combination of arc and straight lines. The upper and lower ends of the flange of the H-shaped steel 6 corresponding to the workpiece to be cut are arc-shaped blades 9, corresponding to the H-shaped workpiece to be cut. The middle part of section steel 6 web position adopts linear blade 10, and arc blade 9 and linear blade 10 are connected together with two demarcation points at the contact point of workpiece H-section steel 6 flange and web. In order to adapt to the shearing of H-shaped steel with different web thickness, such as image 3 As shown, the connection between the arc-shaped blade 9 and the linear blade 10 adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com