Sound-insulation structure of engine compartment

An engine and sound insulation technology, applied in the directions of transportation, packaging, vehicle parts, etc., can solve problems such as environmental noise pollution, and achieve the effects of reducing noise pollution, good sound insulation effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

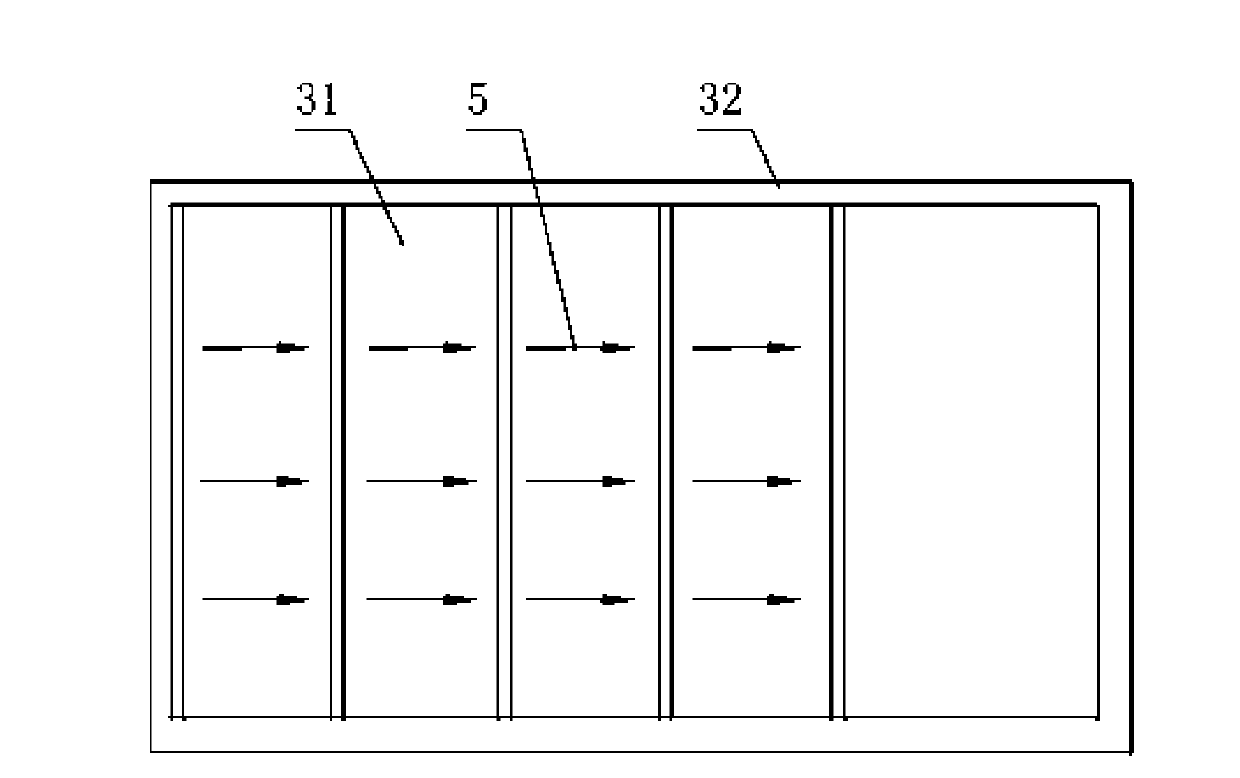

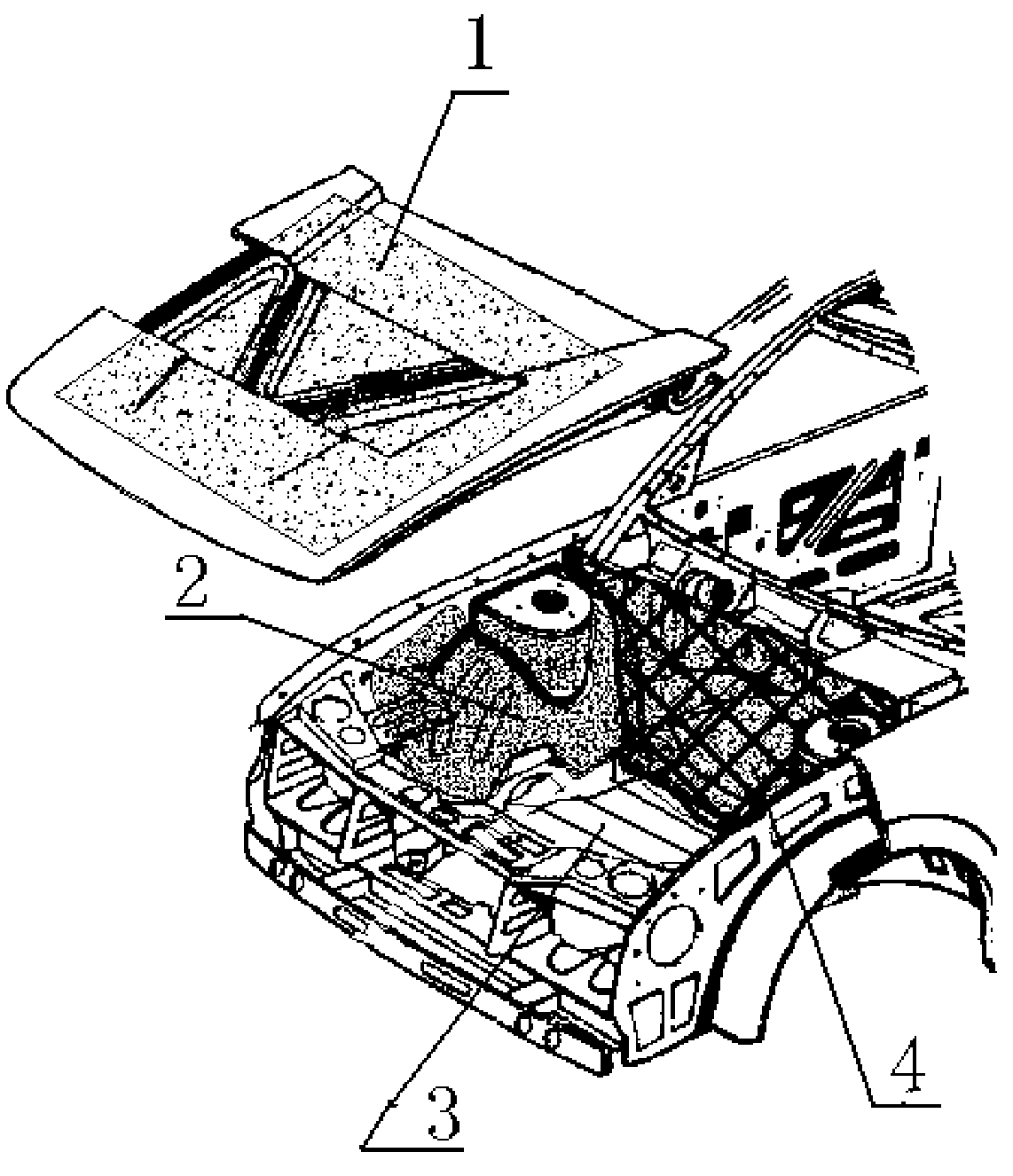

[0022] Embodiment 1: A sound insulation structure of an engine compartment, such as figure 1 , figure 2 , image 3 shown. The rear side of the engine compartment is a firewall 4, the upper side is a cover plate 1, the left and right sides are front wheel cover plates 2, the front side is a radiator, and the front side has an air inlet. The front side of the firewall 4, the lower side of the cover plate 1 and the inner side of the front wheel cover 2 are all provided with a sound insulation layer. The material layer is a glass fiber layer, and the sound-insulating material layer is a sound-insulating felt, and the above-mentioned sound-insulating layers are fixed by buckles. The lower side of the engine compartment has a sound insulation grille 3 arranged horizontally, and the sound insulation grille 3 has a structure such as figure 2 As shown, it includes a rectangular outer frame 32 and grid pages 31 installed on the outer frame 32. There are five grid pages 31 in total...

Embodiment 2

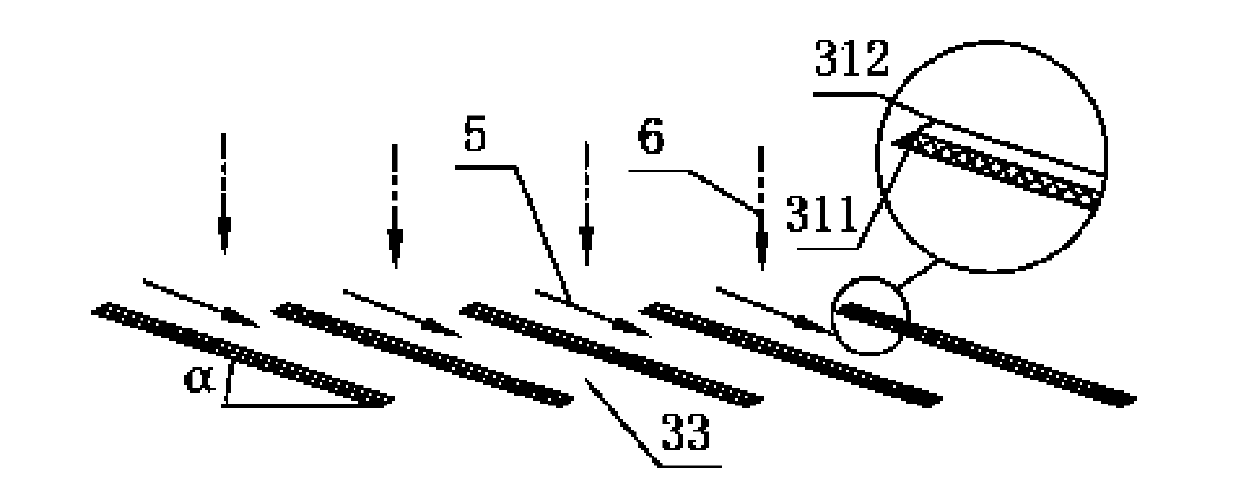

[0024] Embodiment 2, a sound insulation structure of the engine compartment, such as figure 1 , figure 2 , Figure 4 shown. In this embodiment, the grid leaf 31 of the sound insulation grid plate 3 has a double-layer structure. The lower side of the grid leaf 31 is a plastic skeleton layer 312, and the upper side is a sound insulation layer 311. The skeleton layer 312 and the sound insulation layer 311 are glued together. Sticking way is fixed together, and other structures are all the same as in embodiment 1.

[0025] Such as Figure 4 As shown, the noise is absorbed by the sound insulation layer 311 during the downward propagation process, which can effectively reduce the noise in this direction, and the sound insulation layer 311 can absorb and weaken the noise when the noise diffuses through the ventilation hole 33 .

Embodiment 3

[0026] Embodiment 3, a kind of sound insulation structure of engine compartment, such as figure 1 , figure 2 , Figure 5 shown. In this embodiment, the grid leaf 31 of the sound insulation grid plate 3 has a double-layer structure. The upper side of the grid leaf 31 is a plastic skeleton layer 312, and the lower side is a sound insulation layer 311. The skeleton layer 312 and the sound insulation layer 311 are glued together. Sticking way is fixed together, and other structures are all the same as in embodiment 1.

[0027] Such as Figure 5 As shown, in this example, the skeleton layer is located above the sound insulation layer, and the oil leaked from the engine will flow out along the ventilation holes after dripping, which will not cause corrosion to the sound insulation layer, and the sound insulation layer can also reduce noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com