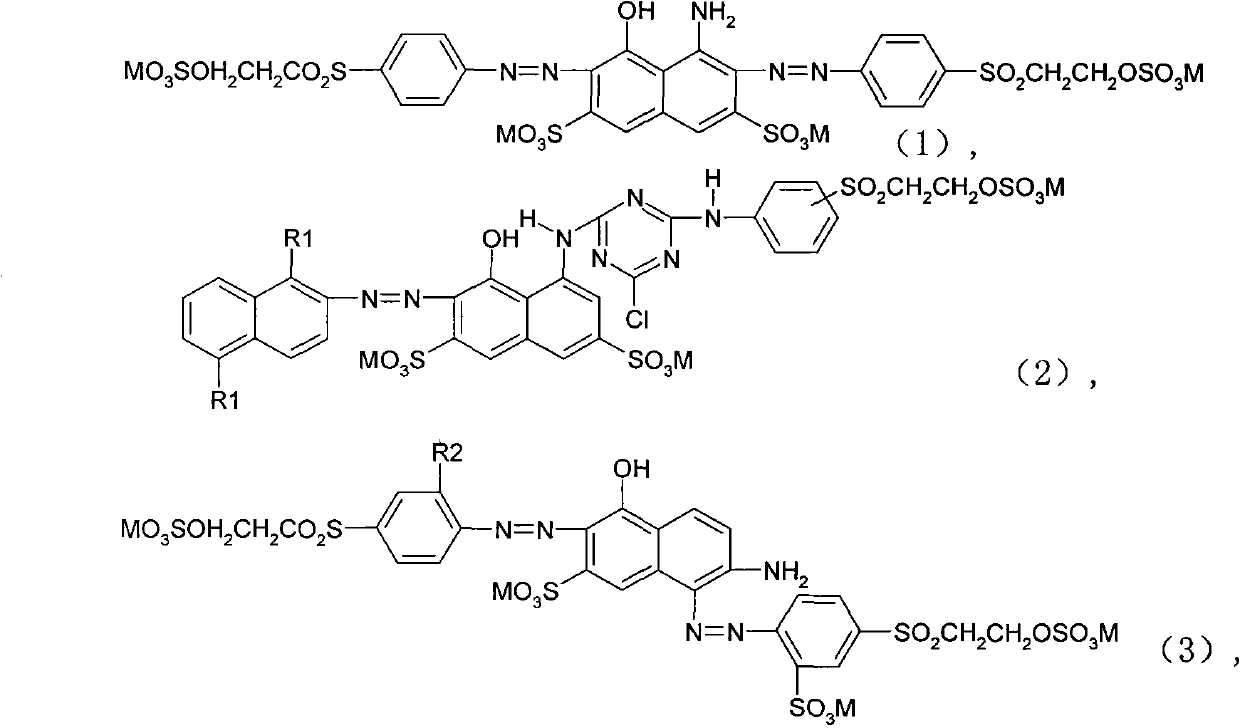

Composite reactive brown dye

A reactive brown and dye technology, applied in the field of dyes, can solve problems such as sewage, and achieve the effects of good dyeing synchronization, high solubility and good levelness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

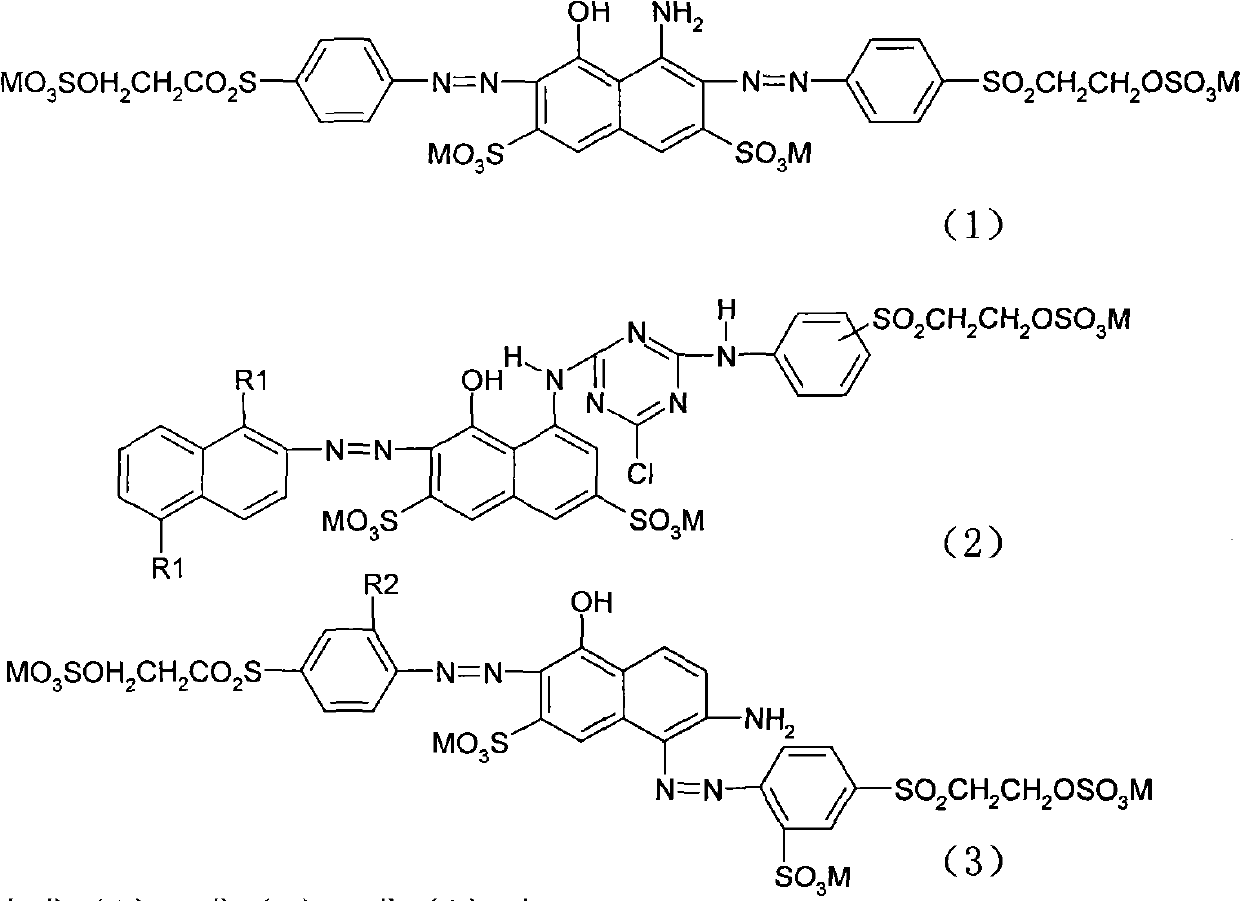

Method used

Image

Examples

Embodiment 1

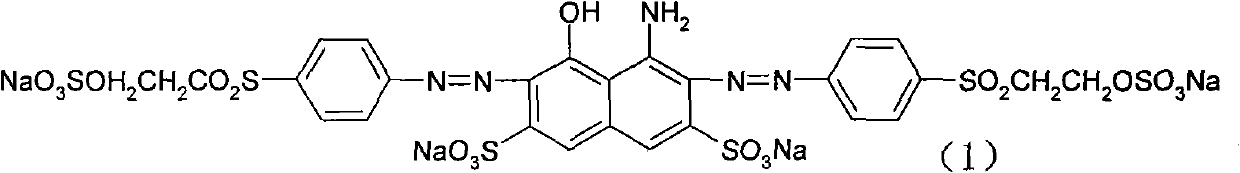

[0023] 20g conforms to formula (1) dyestuff, 15g conforms to formula (2) dyestuff (2-1) and 65g conforms to formula (3-1) dyestuff and obtains composite active brown dyestuff of the present invention through fully mechanically mixing, and this dyestuff can combine The cellulose fiber material is printed and dyed into brown with deep color, good level dyeing property, good reproducibility and good color fastness.

[0024]

Embodiment 2

[0026] The aqueous solution containing 20g formula (1) dyestuff, the aqueous solution containing 15g formula (2) dyestuff (2-1) and the aqueous solution containing 65g formula (3) dyestuff (3-1) are mixed after stirring evenly and drying, obtain the present invention Composite reactive brown dye, this dye can print and dye cellulose fiber material into brown with deep color, good level dyeing, good reproducibility and good color fastness.

Embodiment 3

[0028] 15g conforms to formula (1) dyestuff, 20g conforms to formula (2) dyestuff (2-2) and 65g conforms to formula (3) dyestuff (3-2) and obtains composite active brown dyestuff of the present invention through fully mechanical mixing, this The dye can print and dye the cellulose fiber material into brown with deep color, good level dyeing, good reproducibility and good color fastness.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com