Extraction method of cellulase for improving hydrolysis of lignocellulose

A technology of lignocellulose and cellulase, which is applied in the field of biochemistry and can solve the problems of increasing cost, separation cost, recycling and comprehensive utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

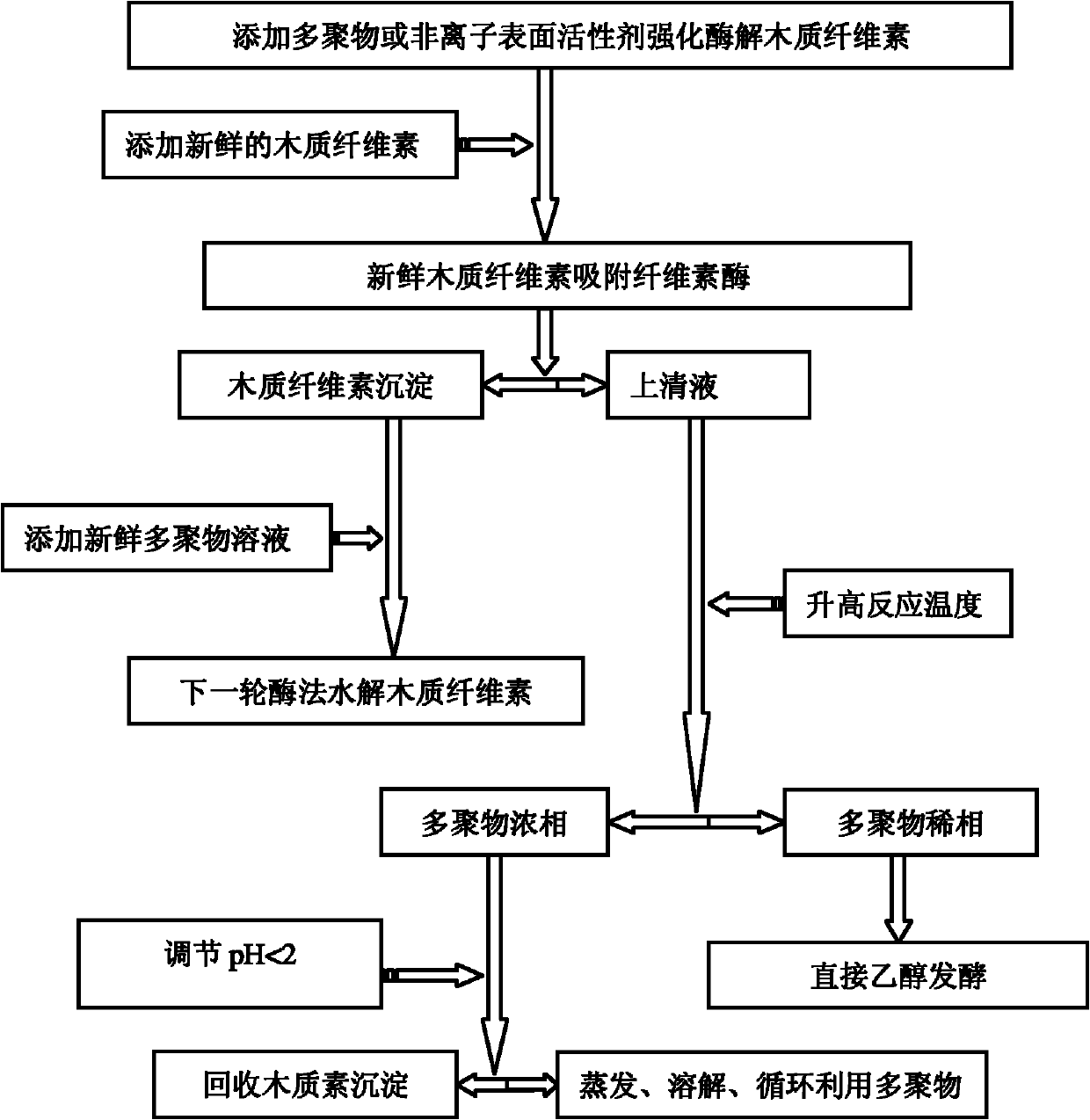

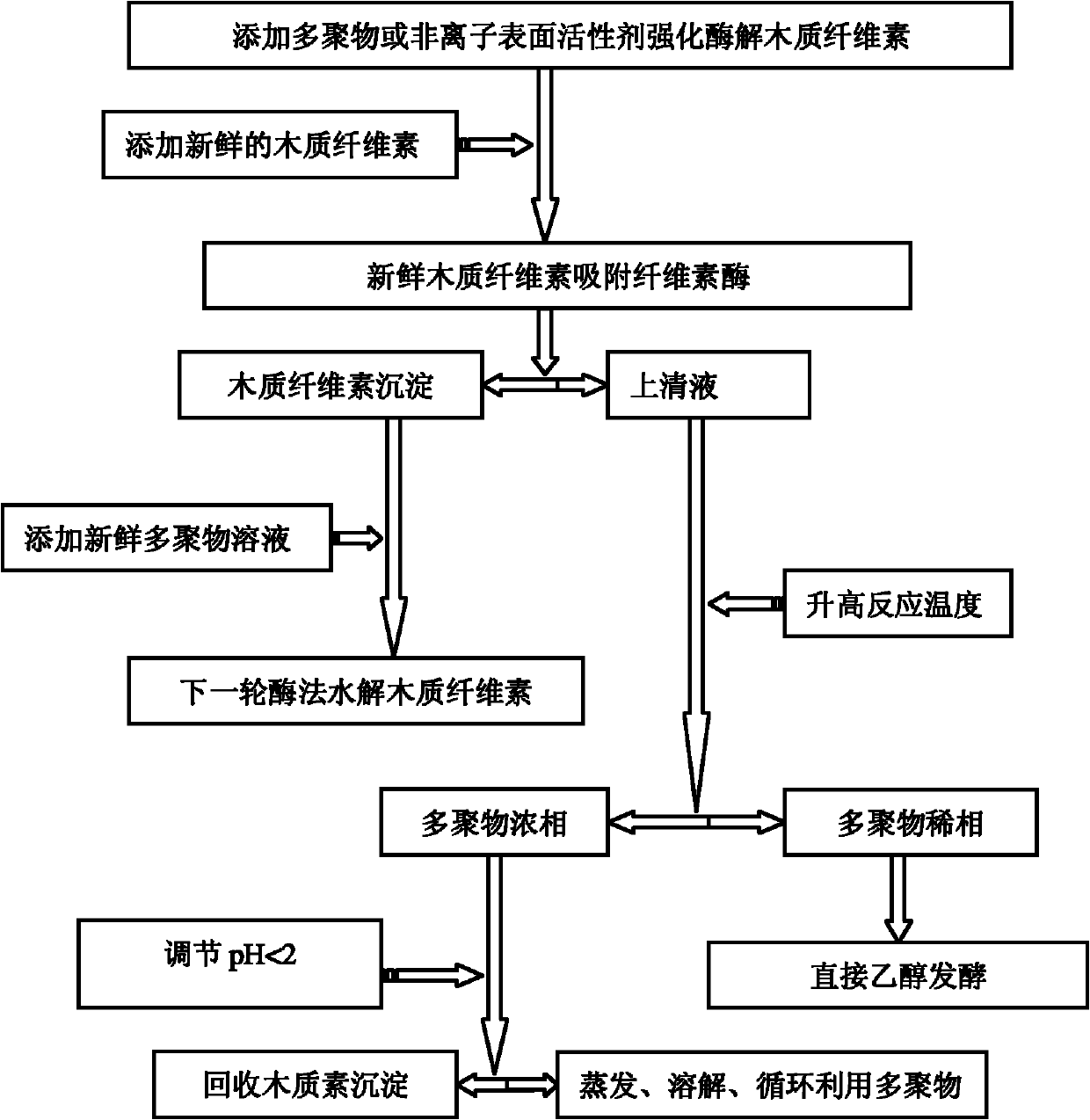

Method used

Image

Examples

Embodiment 1

[0028] Adding 5 g / 100 ml of cellulose Avicel PH 101 and 2 ml / 100 ml cellulase concentration to obtain glucose concentration of 3 g / 100 ml after reacting for 72 hours under conventional conditions.

Embodiment 2

[0030] The addition amount of cellulose Avicel PH 101 is 5g / 100ml, the addition amount of lignin is 1g / 100ml, and the concentration of cellulase is 2ml / 100ml, and the glucose concentration is 2.3g / 100ml after reacting for 72 hours according to conventional conditions.

Embodiment 3

[0032] The concentration of glucose was 1.3g / 100ml after reacting for 72 hours under conventional conditions under the condition that the addition amount of dilute acid pretreated lignocellulose was 5g / 100ml and the concentration of cellulase was 2ml / 100ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com