Infrared light-wave range

A technology of infrared and light wave stoves, applied in the field of stoves, can solve the problems of electromagnetic equipment interference, high energy consumption, human body radiation, etc., and achieve the effects of increasing heat exchange speed, preventing excessive temperature, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

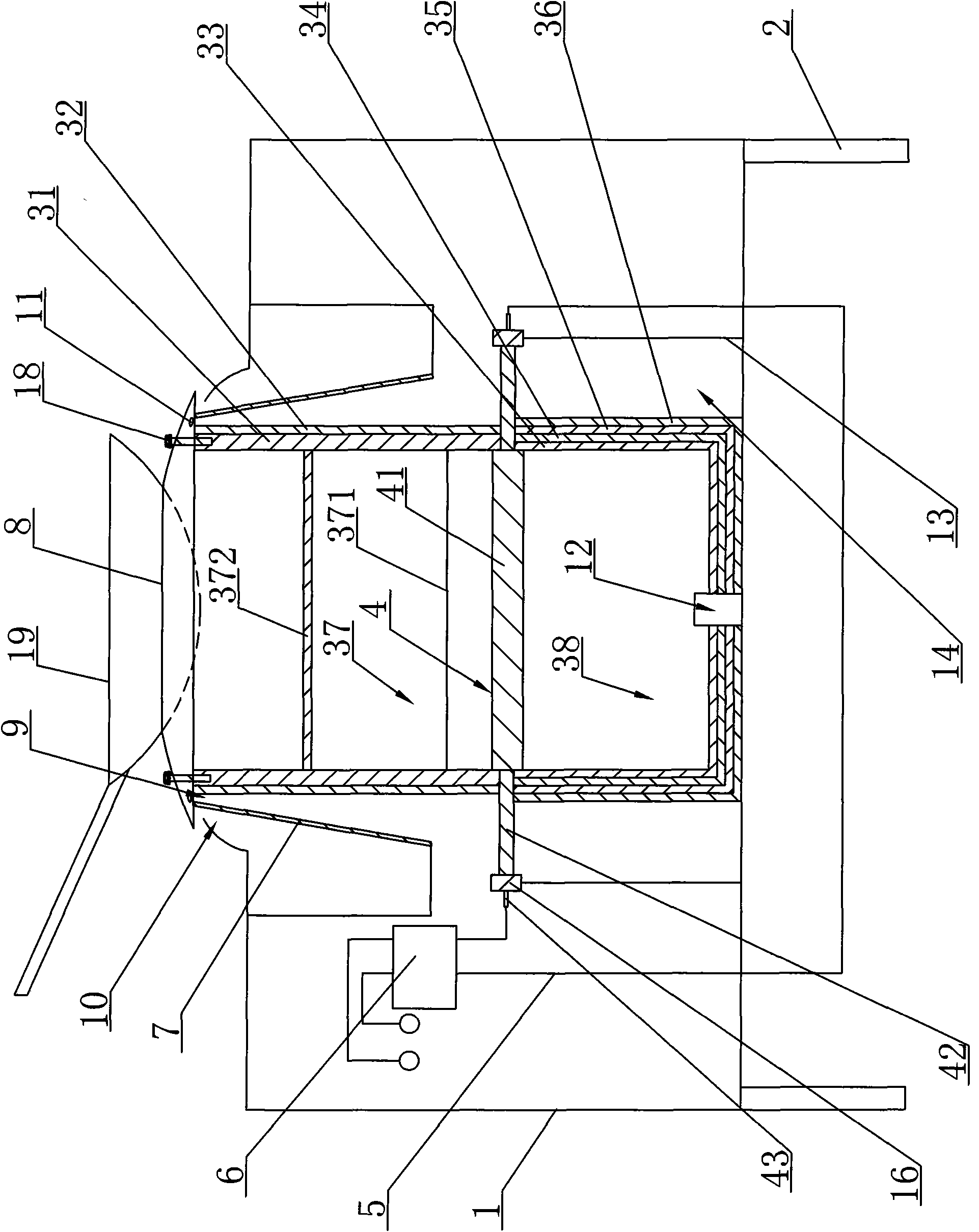

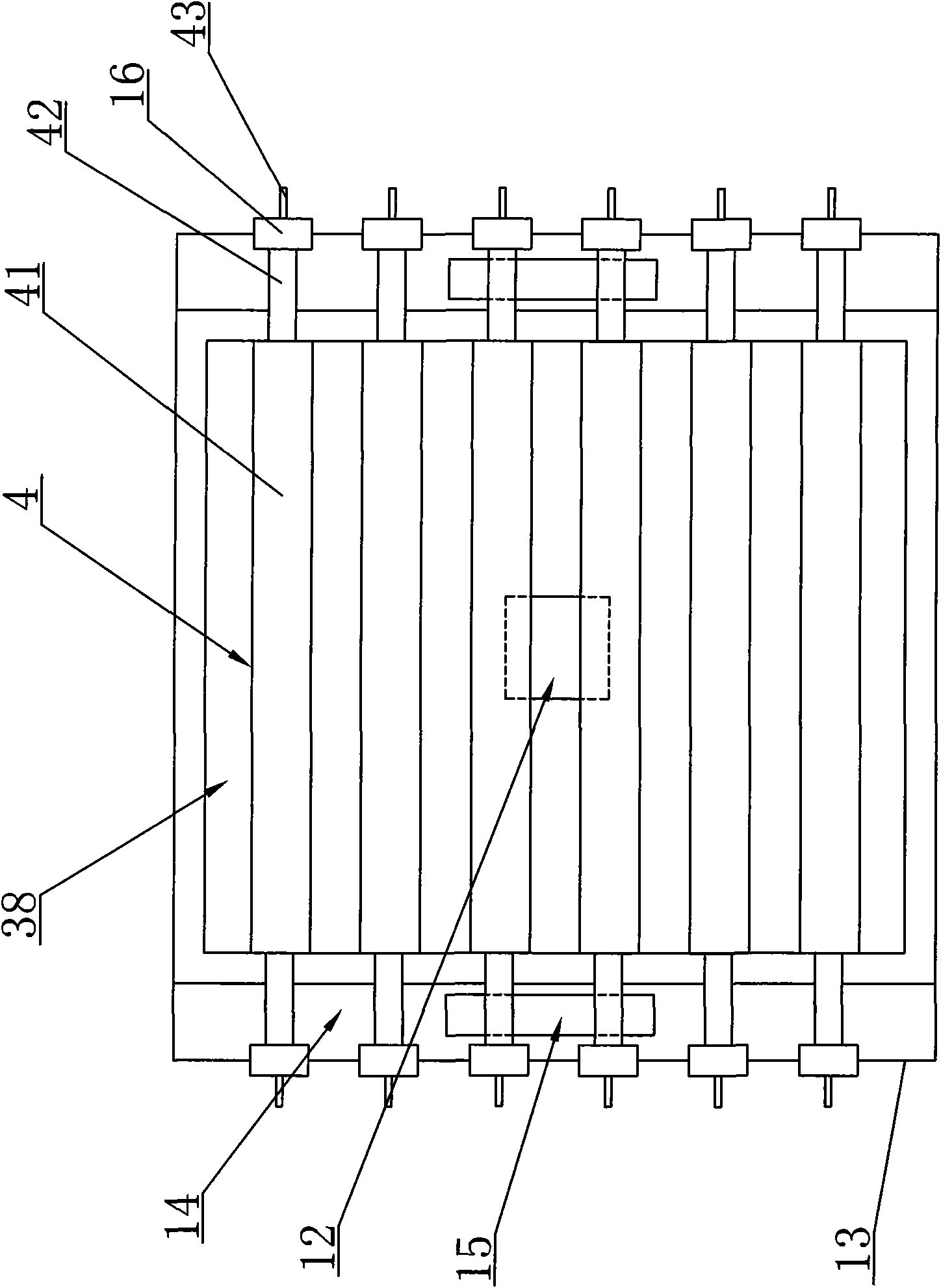

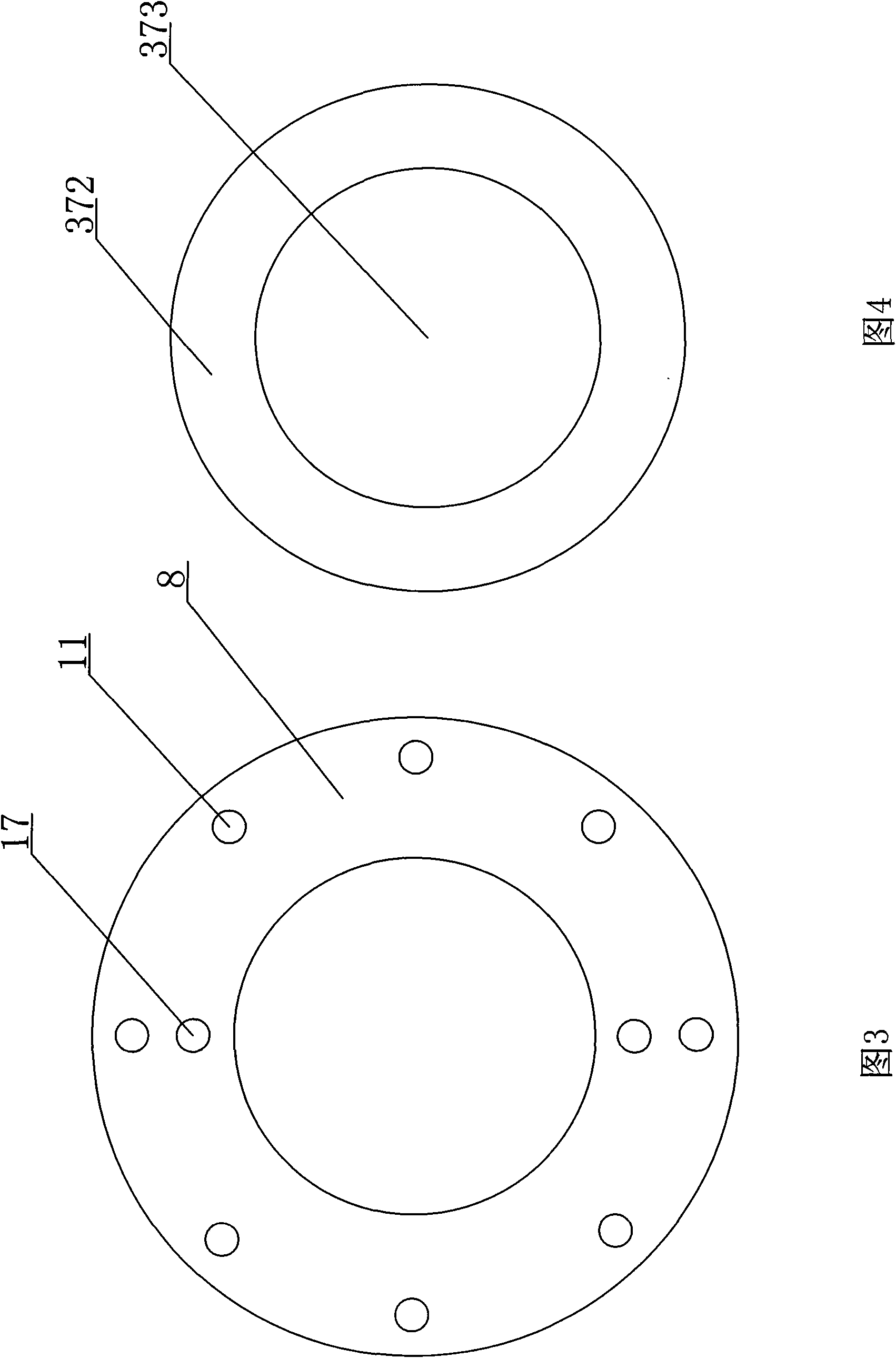

[0015] Such as figure 1 As shown, the infrared light-wave cooker includes: a stainless steel cooker body 1, a support foot 2 is arranged at the bottom of the stainless steel cooker body 1, an upper heat-preservation cooker chamber and a lower heat-retaining cooker chamber are respectively arranged inside the stainless steel cooker body 1, and the lower heat-preservation cooker chamber is arranged on the bottom of the stainless steel cooker body 1 A lower air vent 12 is provided at the bottom of the stove. The upper heat-preservation stove chamber is made up of pig iron layer 31 and the insulation layer 32 that is arranged on the pig iron layer 31 outsides. The lower thermal insulation stove chamber is made up of inner thermal insulation layer 33, the pig iron layer 34 that is arranged on the outer side of inner therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com