Probe test circuit and design method thereof

A technology of test circuit and design method, which is applied in the direction of electronic circuit test, measuring circuit, measuring device, etc., can solve the problems of long development cycle, difficult maintenance and management, and high production cost of test probe card, so as to shorten the development cycle and reduce the The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

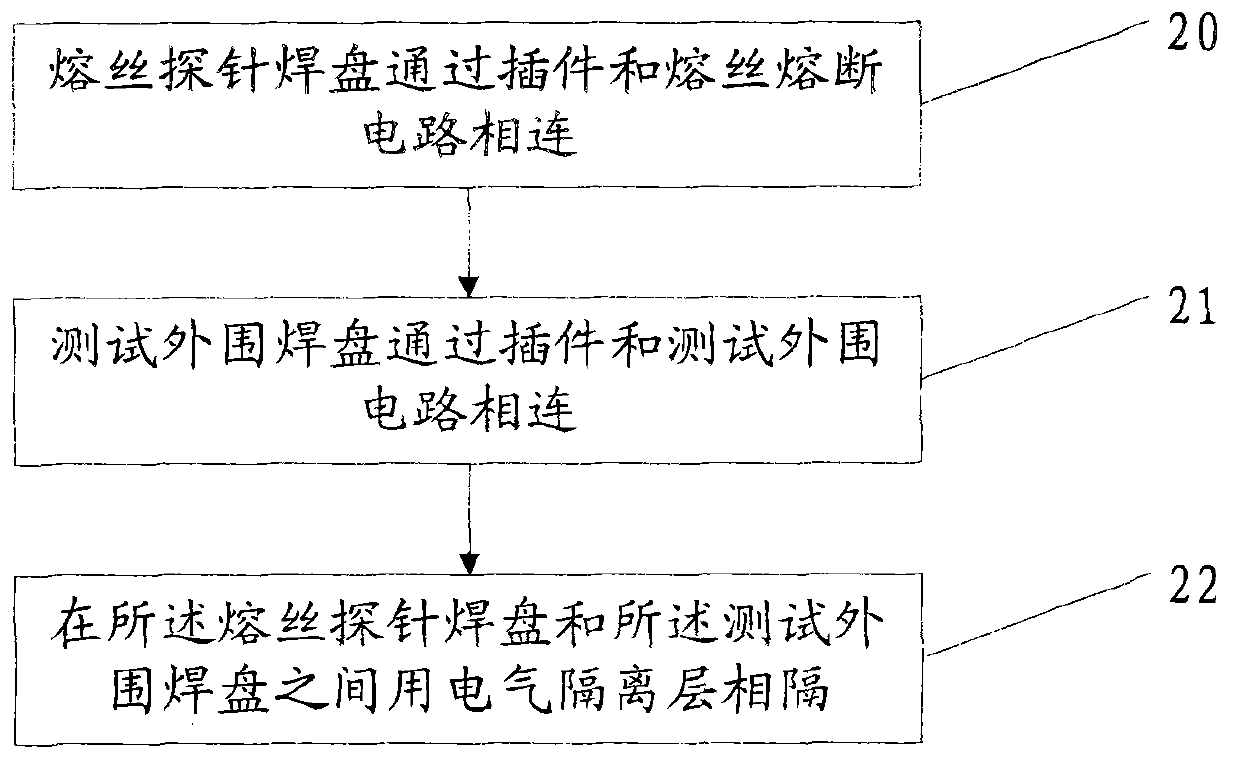

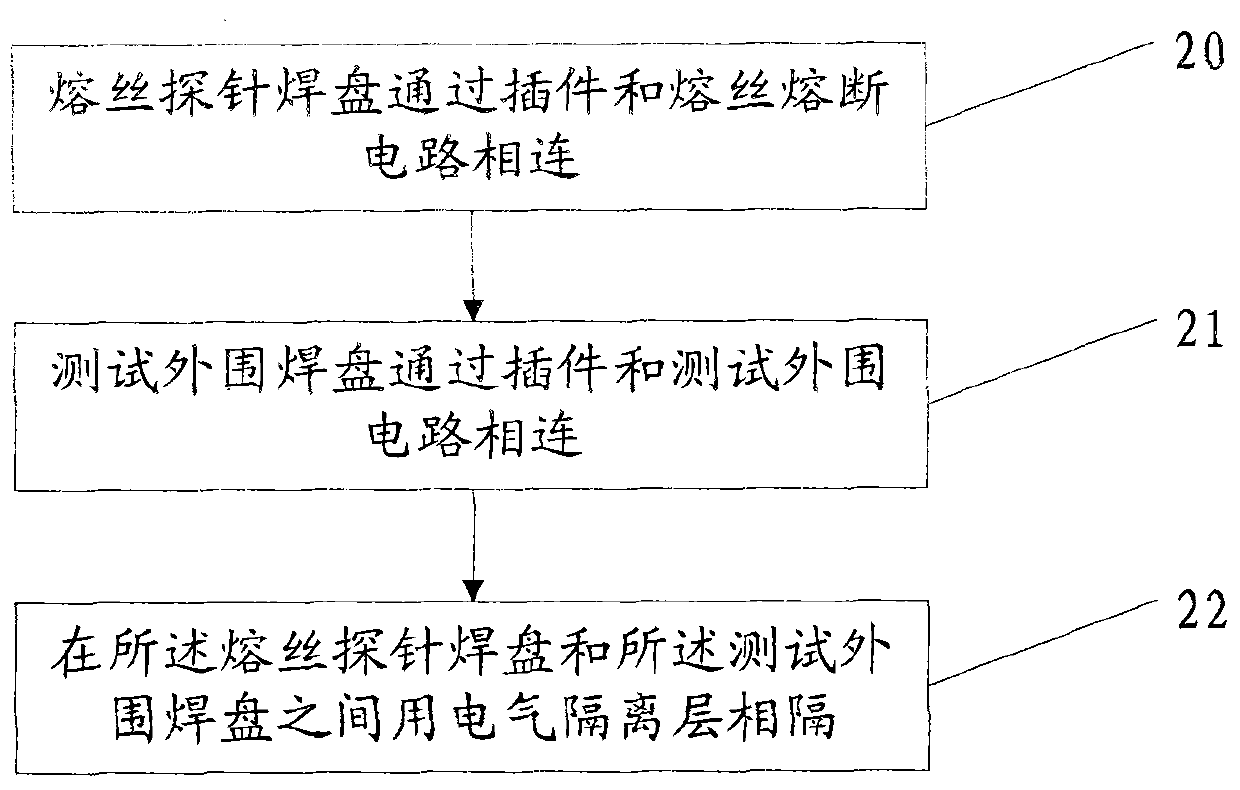

[0020] First, please refer to figure 1 , figure 1 It is a schematic flow chart of a probe test circuit and its design method in the present invention. As can be seen from the figure, the probe test circuit design method of the present invention includes the following steps:

[0021] Step 20: The fuse probe pad is connected to the fuse blowing circuit through a plug-in. The plug-in is a European socket, and the fuse probe pad is ring-shaped. When assembling the test probe, it is only necessary to target For different types of chips, solder the fuse probes of related chips in the fuse probe pads;

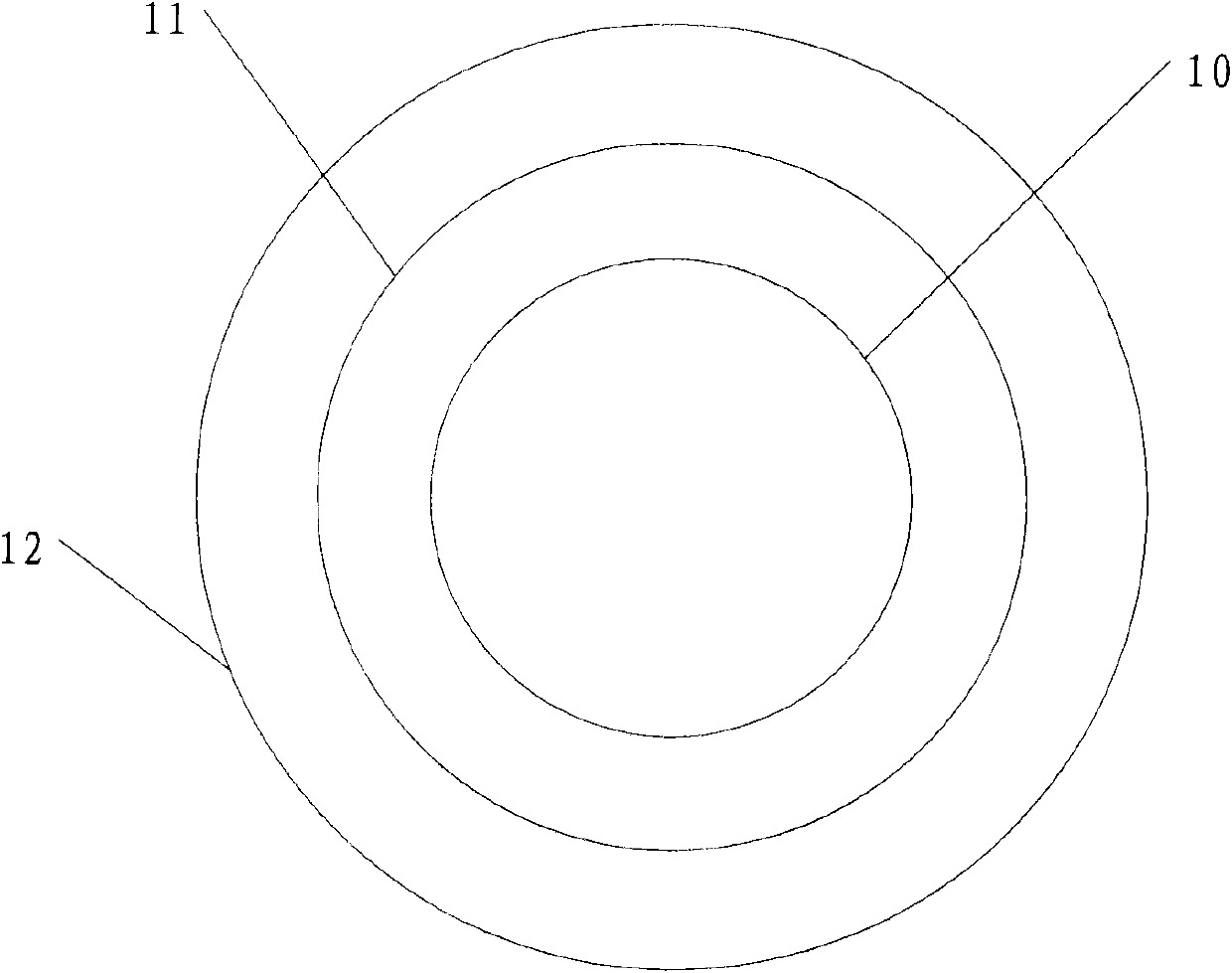

[0022] Step 21: The test peripheral pad is connected to the test peripheral circuit through a plug-in, the test peripheral pad is ring-shaped, the plug-in is a European socket, the fuse probe pad is located in the test peripheral pad, and the fuse probe pad is located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com