Machine for comprehensive treatment of kitchen wastes

A kitchen waste and processor technology, which is applied to sanitary equipment, water supply devices, heating and other directions for toilets to achieve reasonable recycling, strong practicability, and changing operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

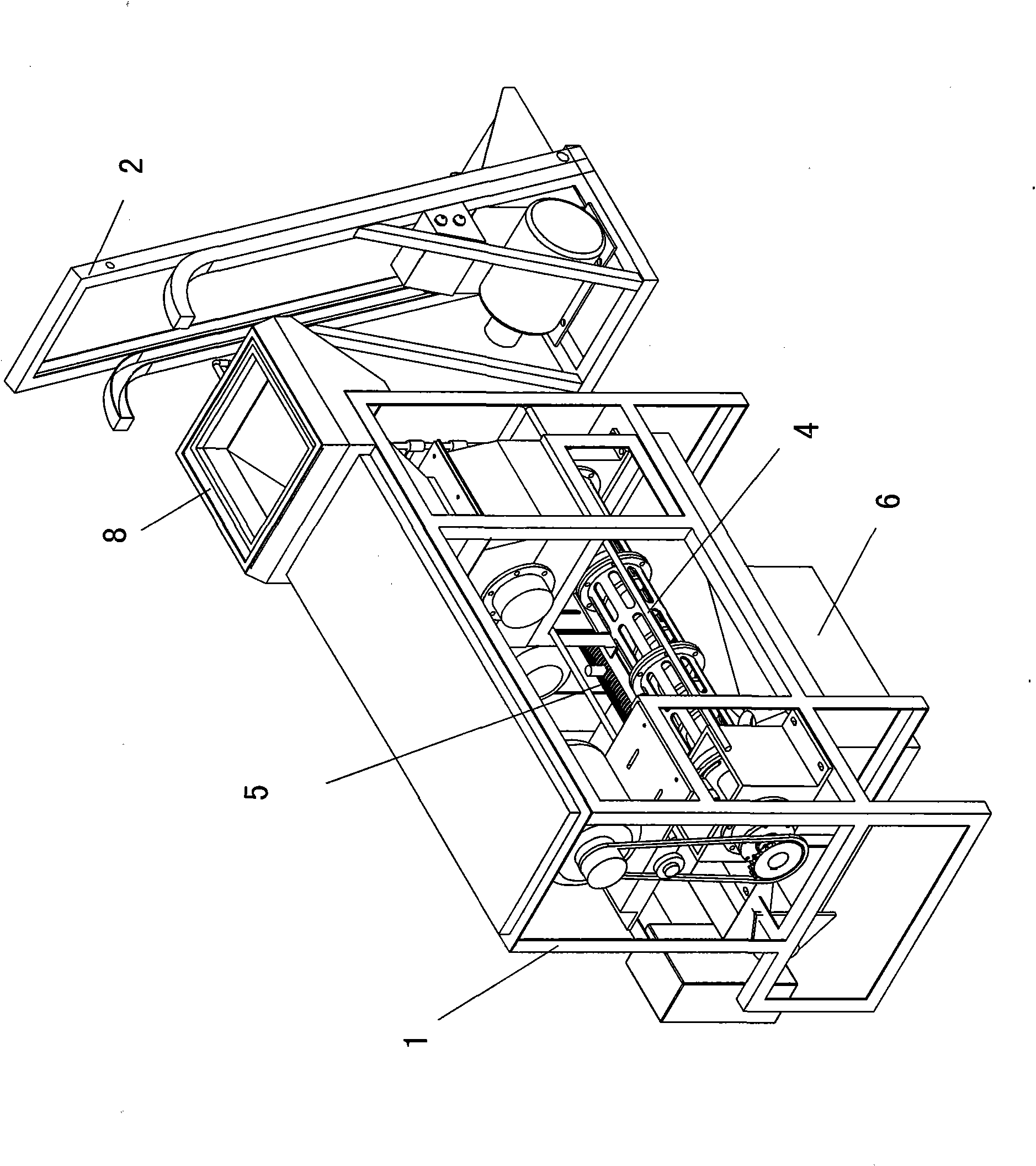

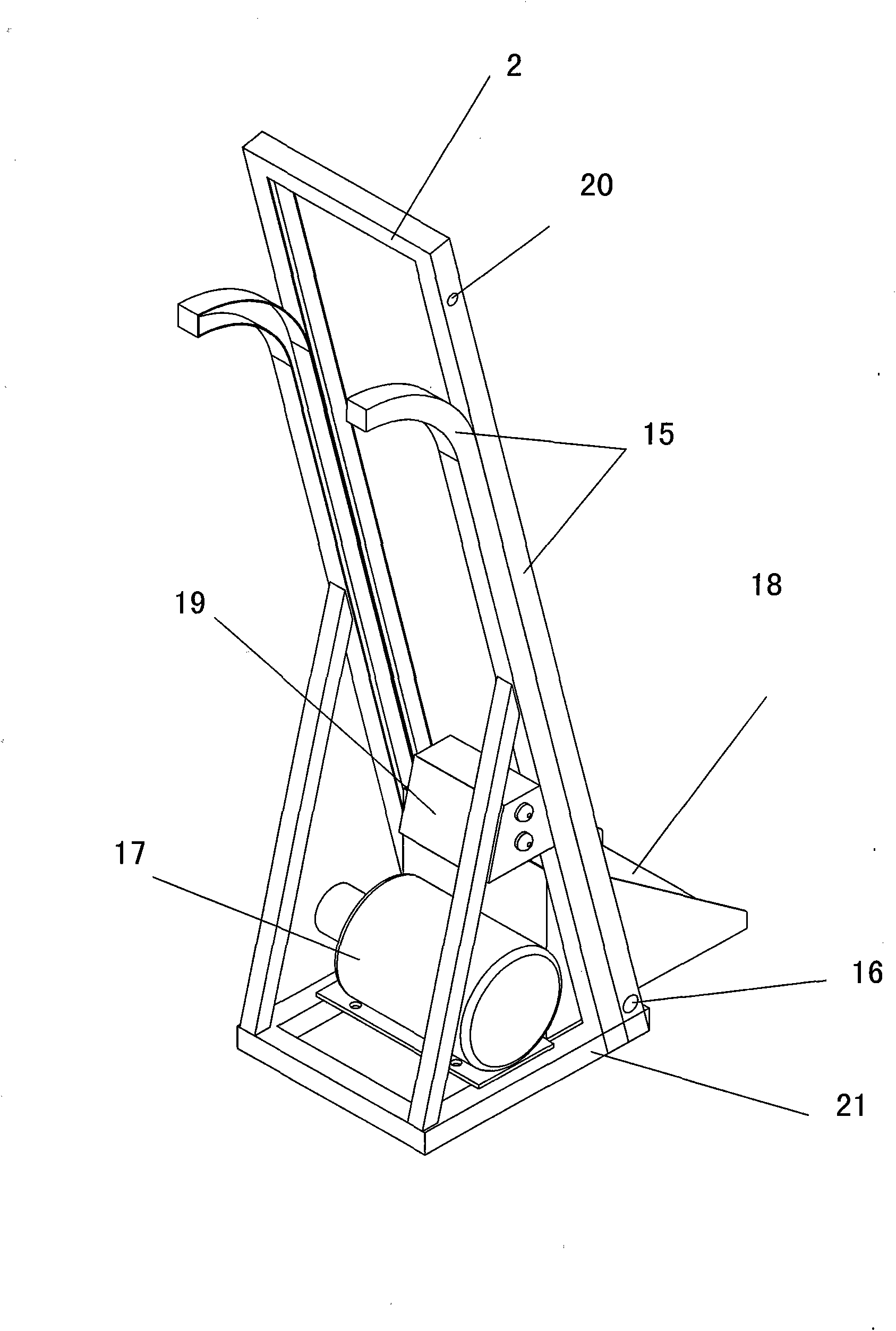

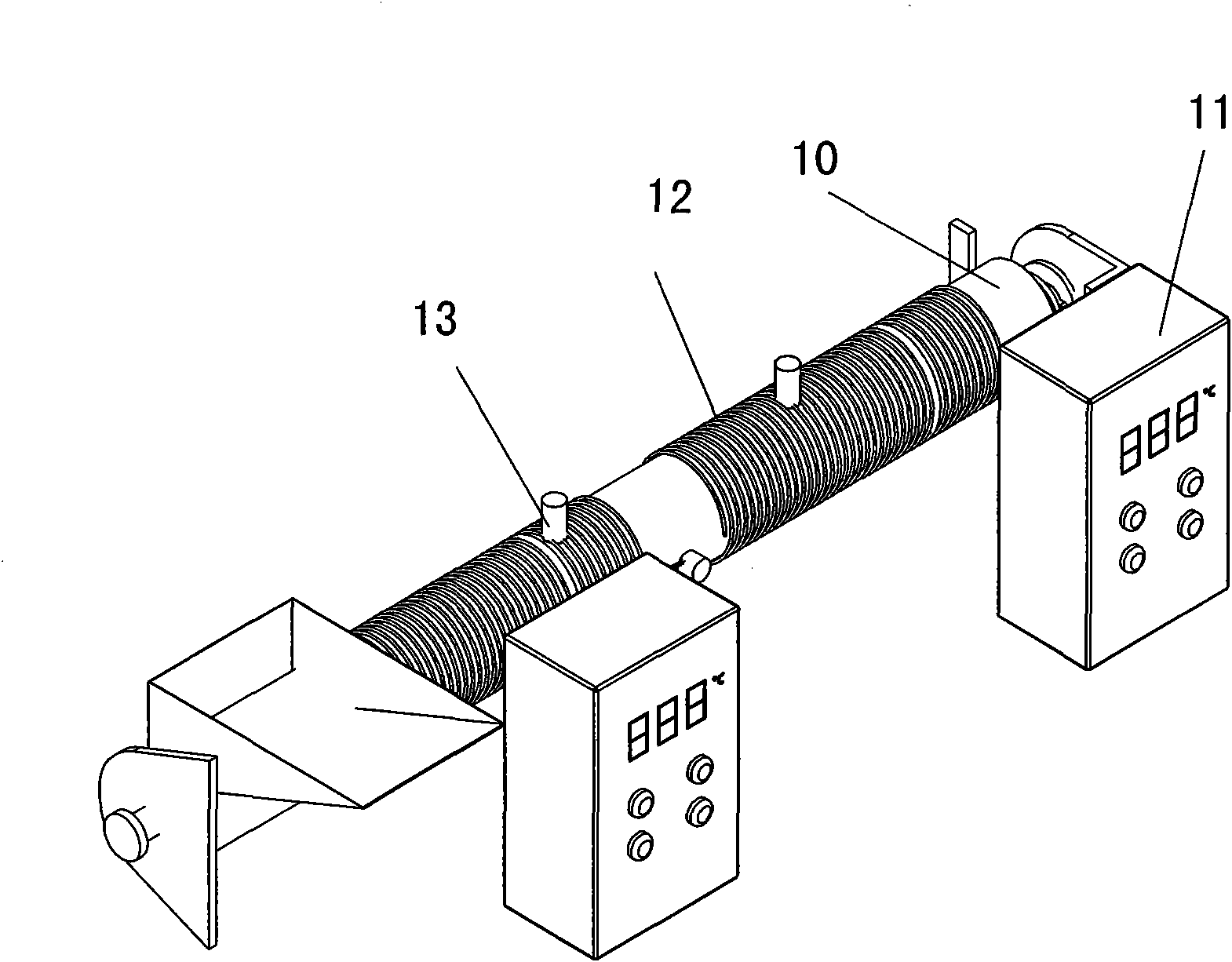

[0016] For an understanding of the invention, see Figure 1 to Figure 6 , accompanying drawing has represented concrete structure of the present invention. The food waste comprehensive processing machine includes a frame 1, an automatic feeding device 2, a material crushing device 3, a spiral dehydration device 4, a drying and sterilization device 5, an oil-water separation device 6, and an operating system 7. The spiral dehydration device 4 connects the materials The crushing device 3, the material crushing device 3 is provided with a feed port 8 connected to the automatic feed device 2, the discharge port of the spiral dehydration device 4 is connected to the feed port of the drying and sterilizing device 5, and the oil-water separation device 6 is set at the lower end of the equipment or externally , The material crushing device can be connected to the drive motor separately. The spiral dehydration device and the drying and sterilizing device can be connected to the drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com