Heavy wheel cast bottom mold making core supporting disc, device and process

A core tray and wheel technology, applied in casting and forming equipment, cores, manufacturing tools, etc., can solve the problems of unable to meet the needs of the production line, unable to achieve mechanized operations, insufficient to support the weight of sand molds, etc., to improve product quality and Labor efficiency, suitable for large batches, and the effect of improving the labor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

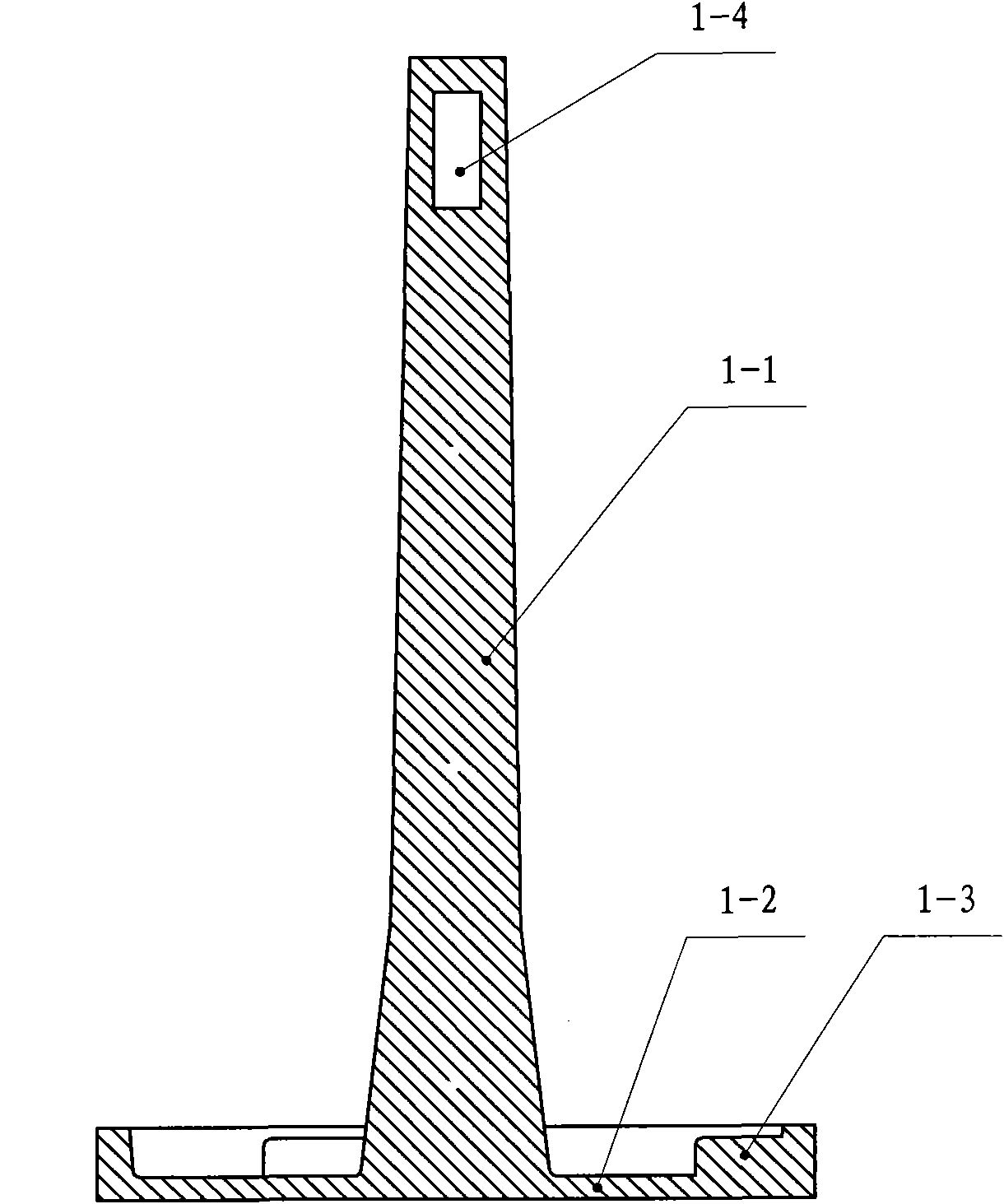

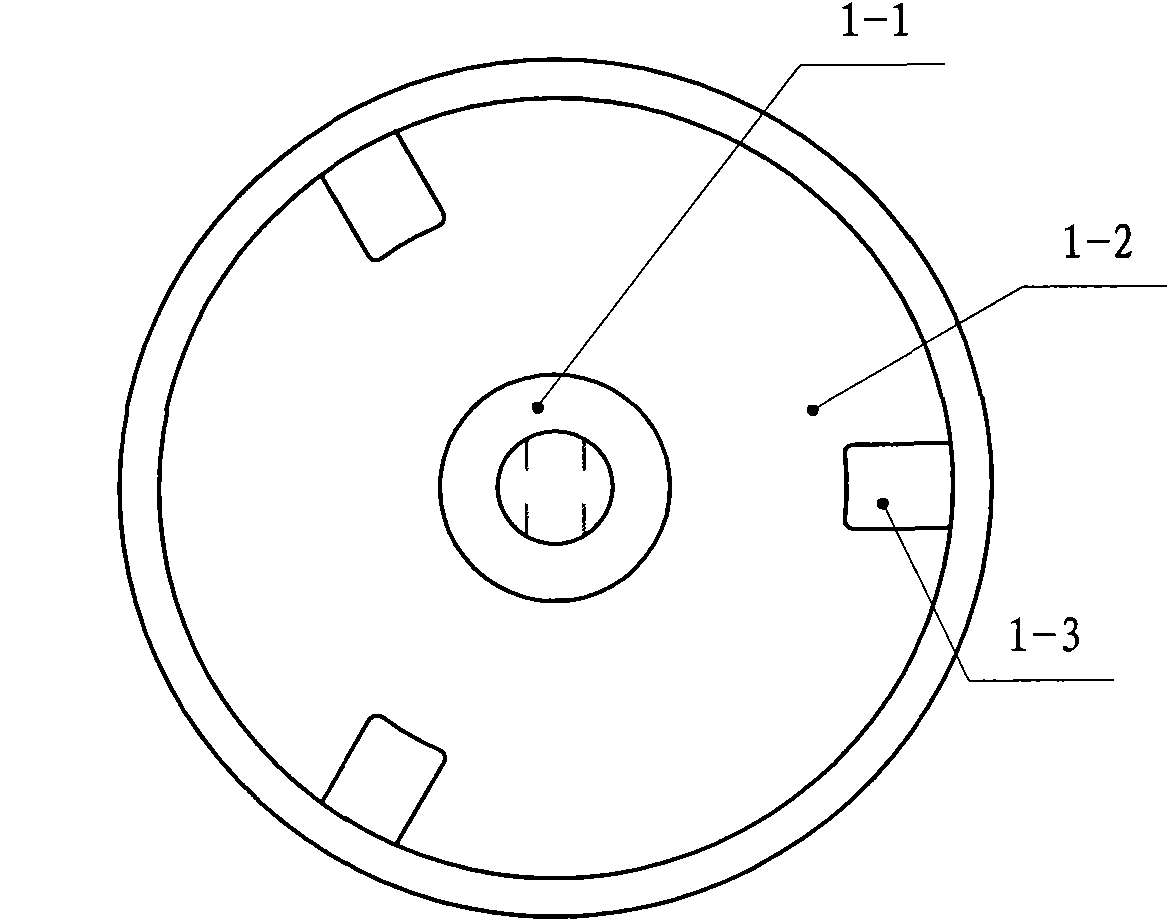

[0047] Embodiment one: see figure 1 , figure 2, a heavy-duty wheel casting base molding in the figure, the core plate contains lifting rod body 1-1 and disc body 1-2 perpendicular to each other, and the lifting rod body 1-1 is thin at the top and thick at the bottom Cone body, the lower end of the lifting rod body 1-1 is connected with the middle part of the disc body 1-2 to form a whole; the upper part of the lifting rod body 1-1 is provided with a through hole 1-4 across. The upper surface of the disc body 1-2 is provided with a pouring channel forming block 1-3 inside the outer edge.

Embodiment 2

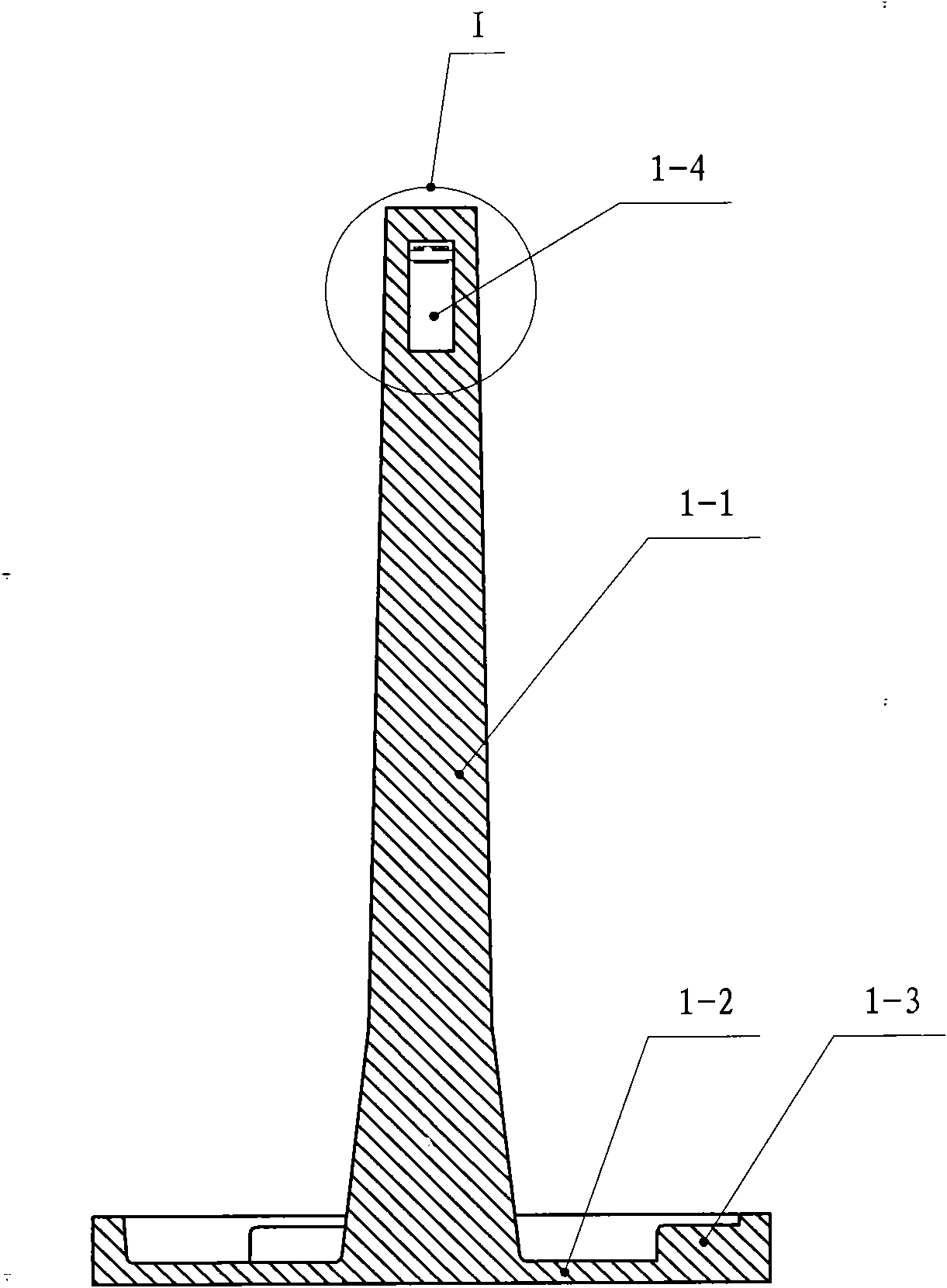

[0048] Embodiment two: see image 3 , figure 2 , Figure 4 , a heavy-duty wheel casting bottom mold molding tray, the tray contains a lifting rod body 1-1 and a disc body 1-2 perpendicular to each other, the lifting rod body 1-1 is a cone with a thin upper part and a thicker lower part , the lower end of the lifting rod body 1-1 is connected with the middle part of the disc body 1-2 to form an integral body; the upper part of the lifting rod body 1-1 is provided with a through hole 1-4 across. The upper surface of the disc body 1-2 is provided with a pouring channel forming block 1-3 inside the outer edge. A rolling sleeve mechanism 1-5 is installed above the through hole 1-4.

Embodiment 3

[0049] Embodiment three: see figure 1 , figure 2 , Figure 5-Figure 10 , a heavy-duty wheel casting bottom molding device, including a sand box, a bottom basin, a mold base, and a lifting template, the bottom basin is fixedly installed in the mold base, and the lifting template is set outside the bottom basin and placed in the mold On the frame, corresponding pin holes are provided between the lower edge of the sand box, the upper edge of the formwork and the lifting template, and matching positioning pins are arranged in the pin holes, and the support core is also installed in the bottom basin. disc, the supporting core disc contains a lifting rod body and a disc body perpendicular to each other. The upper part is provided with a transverse through hole; the center of the inner surface of the bottom of the bottom basin is provided with a depression matching the disc body, the disc body is installed in the depression, and the upper part of the cylindrical surface of the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com