Polypropylene composition for injection molding of automotive part with good appearance and preparation method thereof

A polypropylene composition and composition technology, which is applied in the field of polypropylene compositions, can solve the problems of lack of clear description, low-temperature impact performance and rigidity are not well balanced, and achieve the effect of improving appearance, good low-temperature performance and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

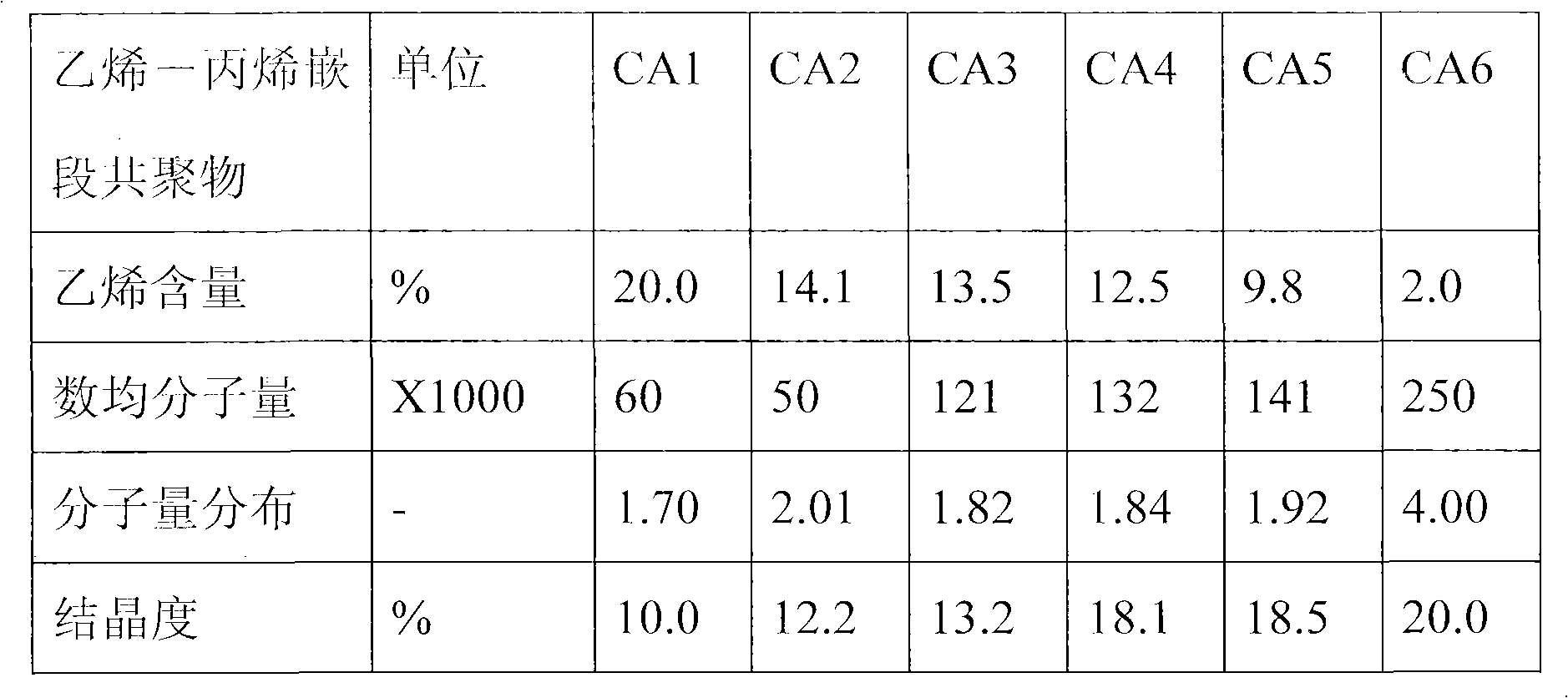

Image

Examples

Embodiment 1

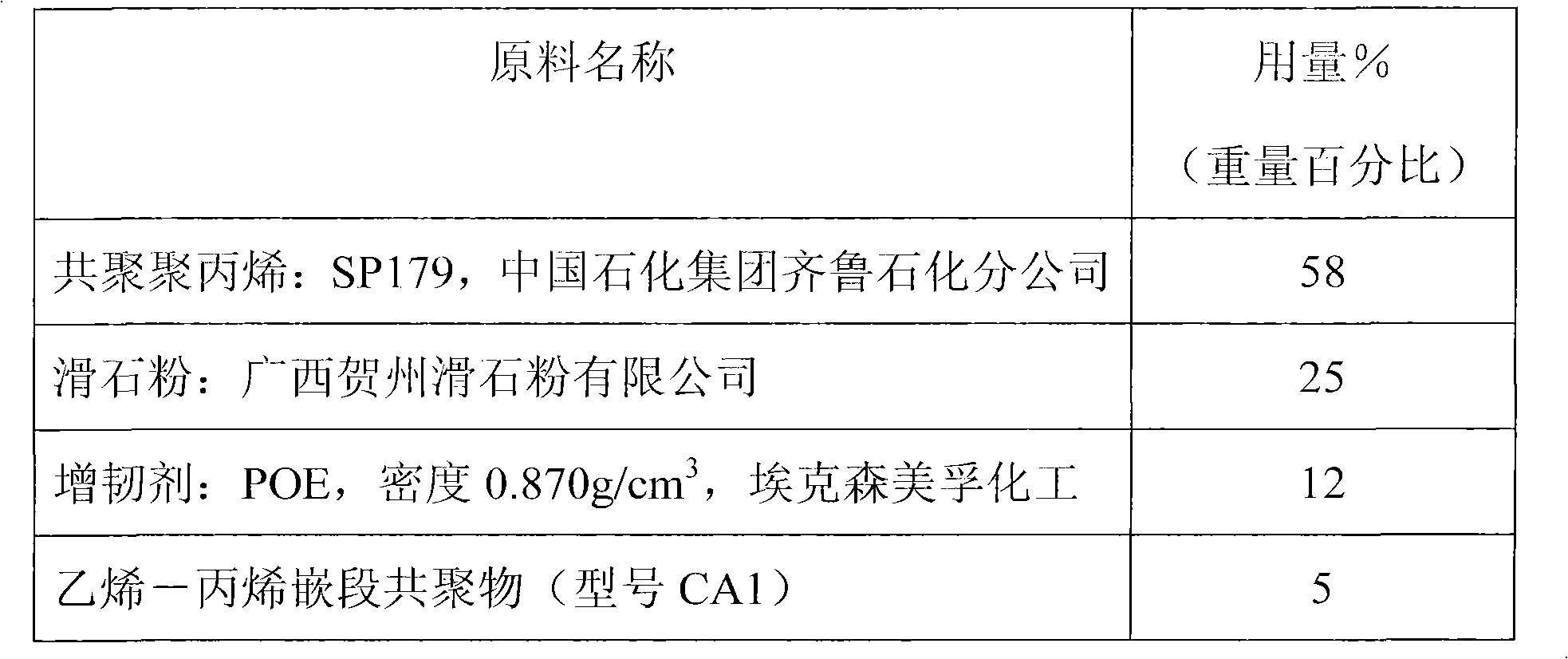

[0040] The composition of the polypropylene composition of this embodiment is shown in Table 2.

[0041] Raw material and consumption of table 2 polypropylene composition

[0042]

[0043] The polypropylene composition of the present embodiment, its preparation method is as follows:

[0044] The raw materials described in Table 2 are weighed according to their dosage ratios. After mixing evenly, add them to a twin-screw extruder, melt and knead at a temperature of 190-210°C, extrude and granulate, water-cool and air-dry, and the particle size is 3mm. Just pack it.

[0045] The detection results of the polypropylene composition of this embodiment are shown in Table 3.

[0046] Table 3 product performance test results

[0047] performance

[0048] Notched Izod Impact Strength -30°C

[0049] In this embodiment, ethylene-propylene block copolymer is added, and its appearance performance is better, and there is no tiger skin pattern on the surface of the wor...

Embodiment 2

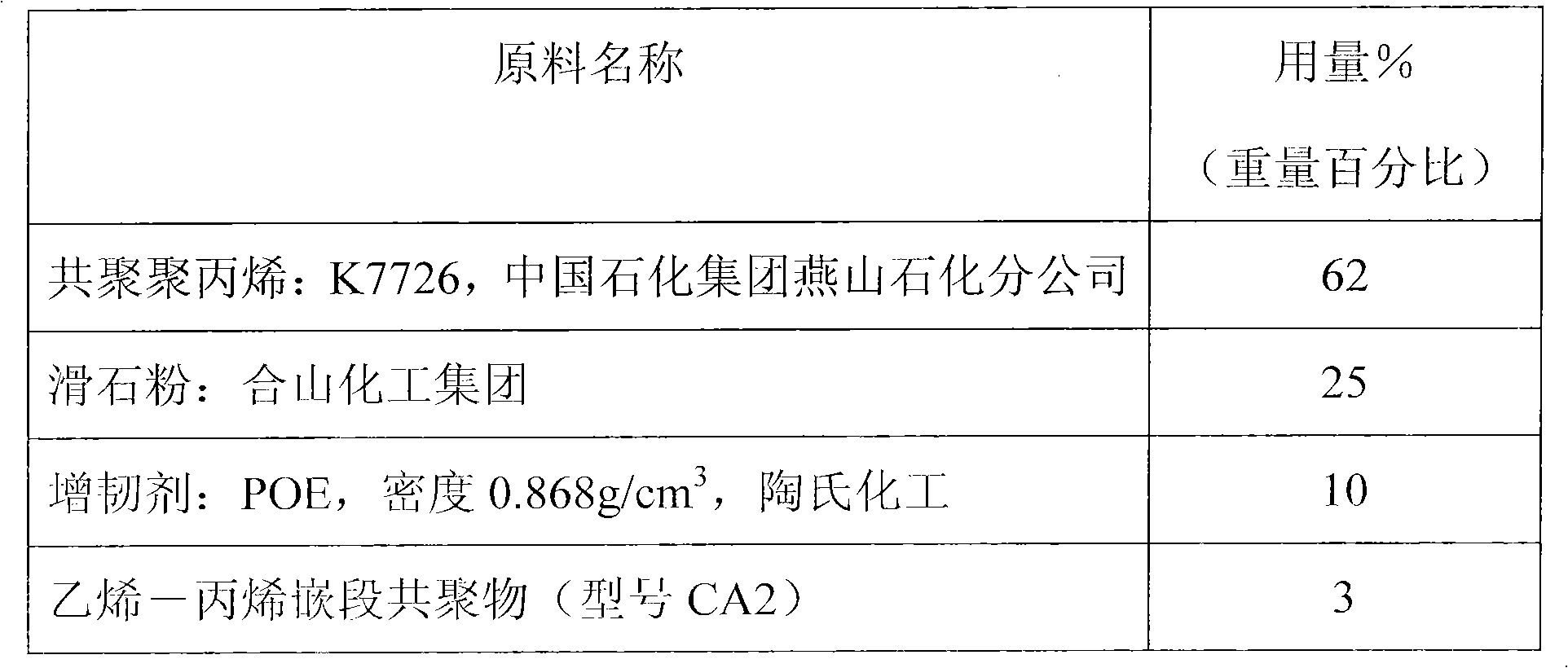

[0051] The composition of the polypropylene composition of this embodiment is shown in Table 4.

[0052] Raw material and consumption of table 4 polypropylene composition

[0053]

[0054] The polypropylene composition of this embodiment, its preparation method is as embodiment 1.

[0055] The detection results of the polypropylene composition of this embodiment are shown in Table 5.

[0056] Table 5 product performance test results

[0057] performance

[0058] Appearance evaluation

Embodiment 3

[0060] The composition of the polypropylene composition of this embodiment is shown in Table 6.

[0061] Raw material and consumption of table 6 polypropylene composition

[0062]

[0063] The polypropylene composition of this embodiment, its preparation method is as embodiment 1.

[0064] The detection results of the polypropylene composition of this embodiment are shown in Table 7.

[0065] Table 7 product performance test results

[0066] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Izod notched impact strength | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com