Sealing adhesive and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

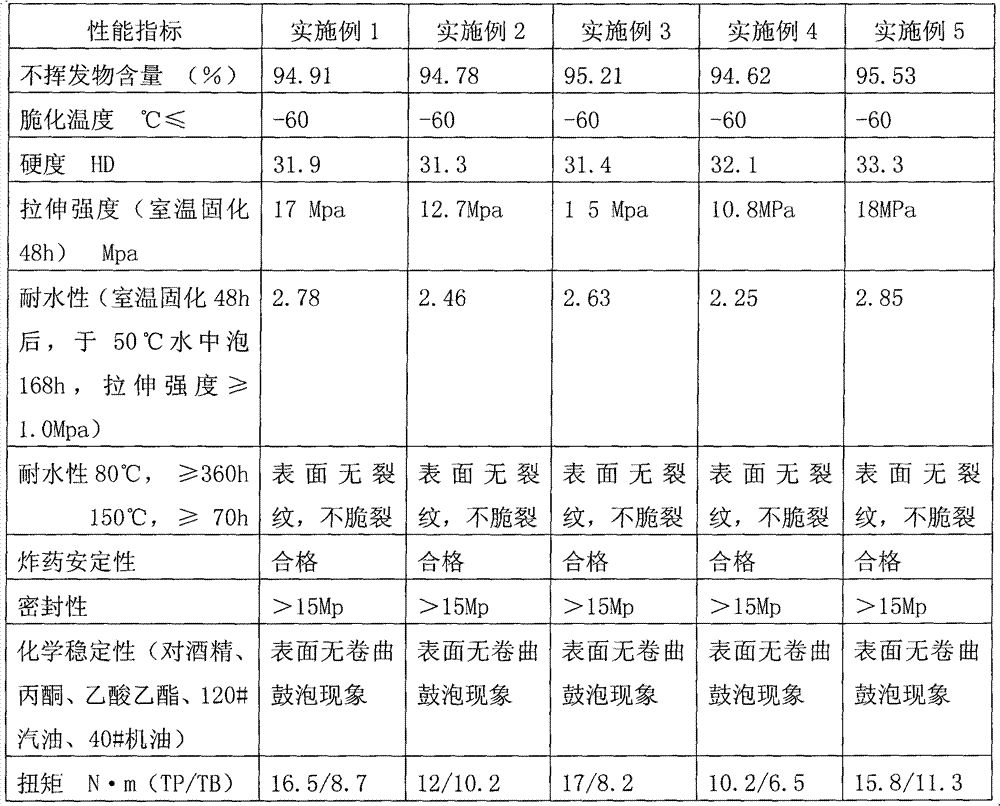

Examples

Embodiment 1

[0045] Embodiment 1, prepare raw material by following formula:

[0046] Ethoxylated bisphenol A dimethacrylate 30 kg;

[0047] Modified E-44 epoxy resin 18 kg;

[0048] Lauryl acrylate 3 kg;

[0049] 55 kg of triethylene glycol dimethacrylate;

[0050] Initiator 1 kg;

[0051] Stabilizer 0.01 kg;

[0052] Accelerator 1 kg;

[0053]Accelerator 2 kg;

[0054] Metal chelating agent 0.1 kg;

[0055] Filling 4 kg.

[0056] Among the raw materials prepared above, except for the accelerator, mix the rest of the raw materials together, heat up, stir at a temperature of 55-70°C for 3-5 hours to completely dissolve the solids, and then cool down to cool down at 40°C. Add the accelerator at a temperature of ~50°C and stir evenly.

[0057] Wherein, the preparation process of modified E-44 epoxy resin is: 40~80 parts by weight of E-44 epoxy resin, 20~50 parts by weight of methacrylic acid, 1~2 parts by weight of p-phenol methyl ether are mixed together, Heating to raise the temp...

Embodiment 2

[0061] Embodiment 2, prepare raw material by following formula:

[0062] 40 kg of ethoxylated bisphenol A dimethacrylate;

[0063] Modified E-44 epoxy resin 10 kg;

[0064] Lauryl acrylate 5 kg;

[0065] 35 kg of triethylene glycol dimethacrylate;

[0066] Initiator 1.5 kg;

[0067] Stabilizer 0.04 kg;

[0068] Accelerator 3 kg;

[0069] Accelerator 5 kg;

[0070] Metal chelating agent 1.5 kg;

[0071] Filling 4.5 kg.

[0072] Among the raw materials prepared above, except for the accelerator, mix the rest of the raw materials together, heat up, stir at a temperature of 55-70°C for 3-5 hours to completely dissolve the solids, and then cool down to cool down at 40°C. Add the accelerator at a temperature of ~50°C and stir evenly.

[0073] Wherein, the preparation process of modified E-44 epoxy resin is: 40~80 parts by weight of E-44 epoxy resin, 20~50 parts by weight of methacrylic acid, 1~2 parts by weight of p-phenol methyl ether are mixed together, Heating to raise ...

Embodiment 3

[0077] Embodiment 3, prepare raw material by following formula:

[0078] Ethoxylated bisphenol A dimethacrylate 20 kg;

[0079] Modified E-44 epoxy resin 20 kg;

[0080] Lauryl acrylate 0.5 kg;

[0081] 60 kg of triethylene glycol dimethacrylate;

[0082] 5 kg of phenolic resin;

[0083] Initiator 5 kg;

[0084] Stabilizer 0.05 kg;

[0085] Accelerator 4 kg;

[0086] Accelerator 0.1 kg;

[0087] Metal chelating agent 0.5 kg;

[0088] Filling 6 kg.

[0089] Among the raw materials prepared above, except for the accelerator, mix the rest of the raw materials together, heat up, stir at a temperature of 55-70°C for 3-5 hours to completely dissolve the solids, and then cool down to cool down at 40°C. Add the accelerator at a temperature of ~50°C and stir evenly.

[0090] Wherein, the preparation process of modified E-44 epoxy resin is: 40~80 parts by weight of E-44 epoxy resin, 20~50 parts by weight of methacrylic acid, 1~2 parts by weight of p-phenol methyl ether are mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com