Improved electronic throttle body

An electronic throttle body and throttle technology, which is applied to the sealing device of the engine, the addition of non-fuel substances to the fuel, and engine components, etc., can solve the problems of throttle shaft deformation, throttle body pinning, and increased fuel consumption. Power and fuel economy, unique structural design, and the effect of improving intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

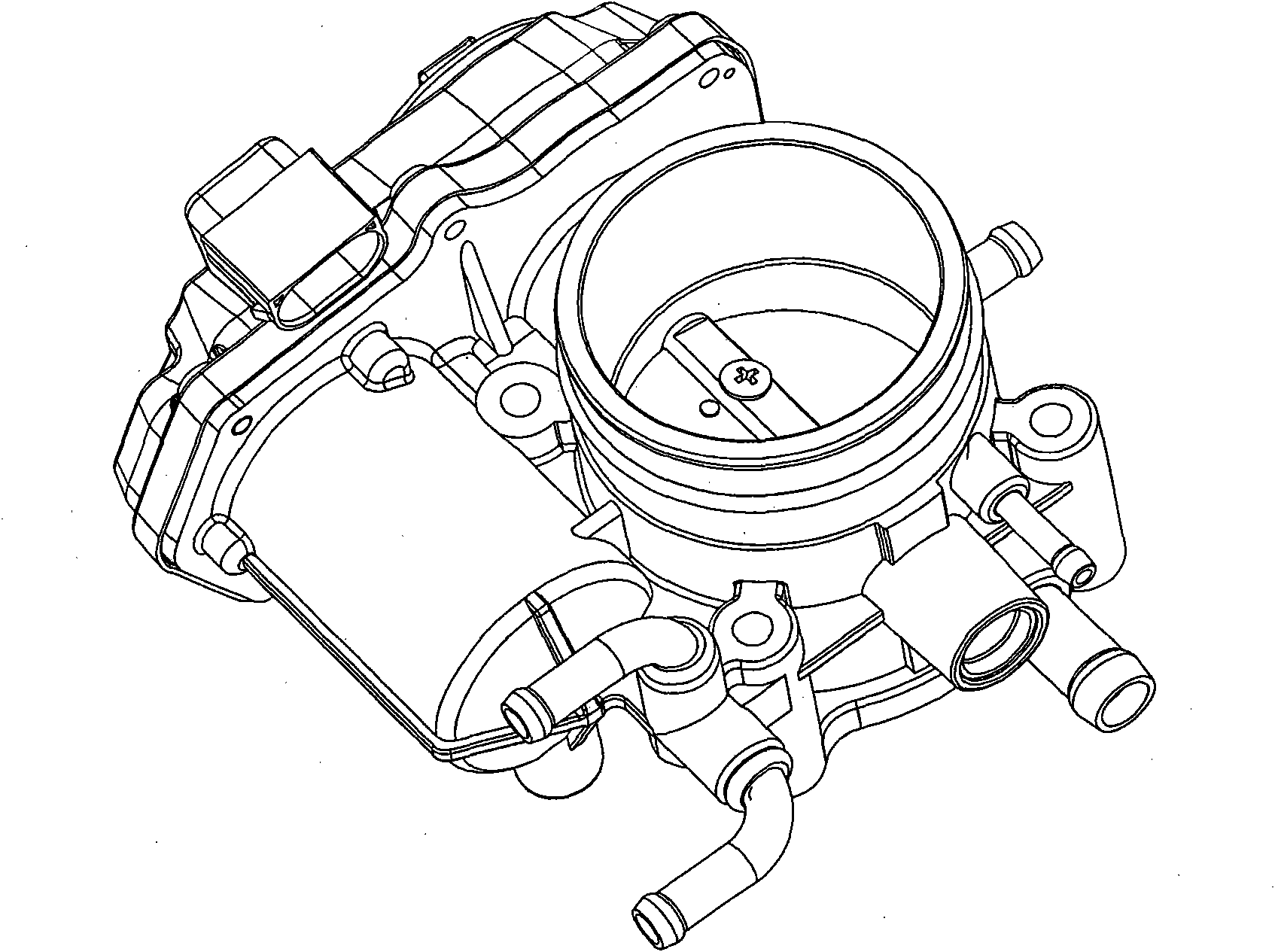

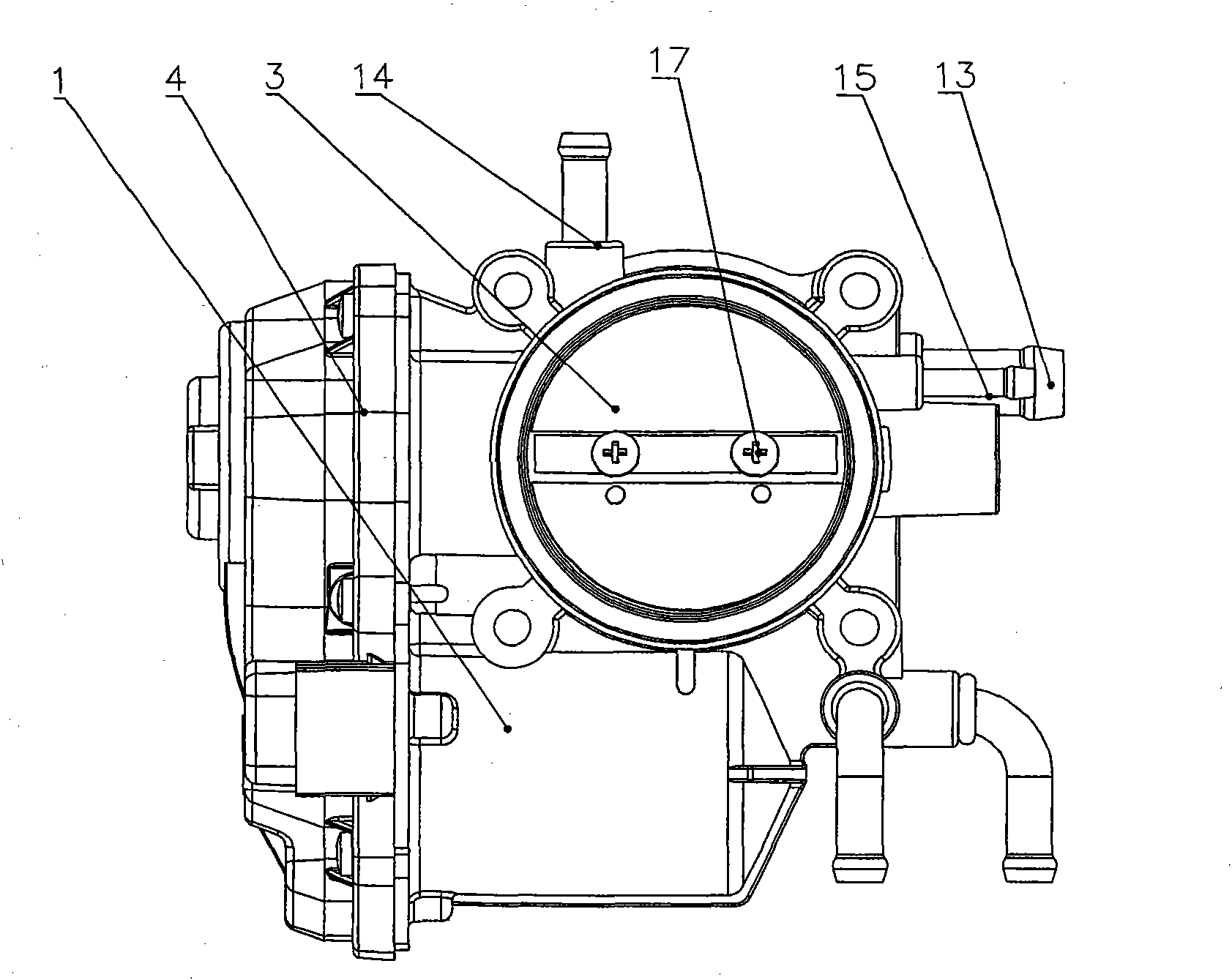

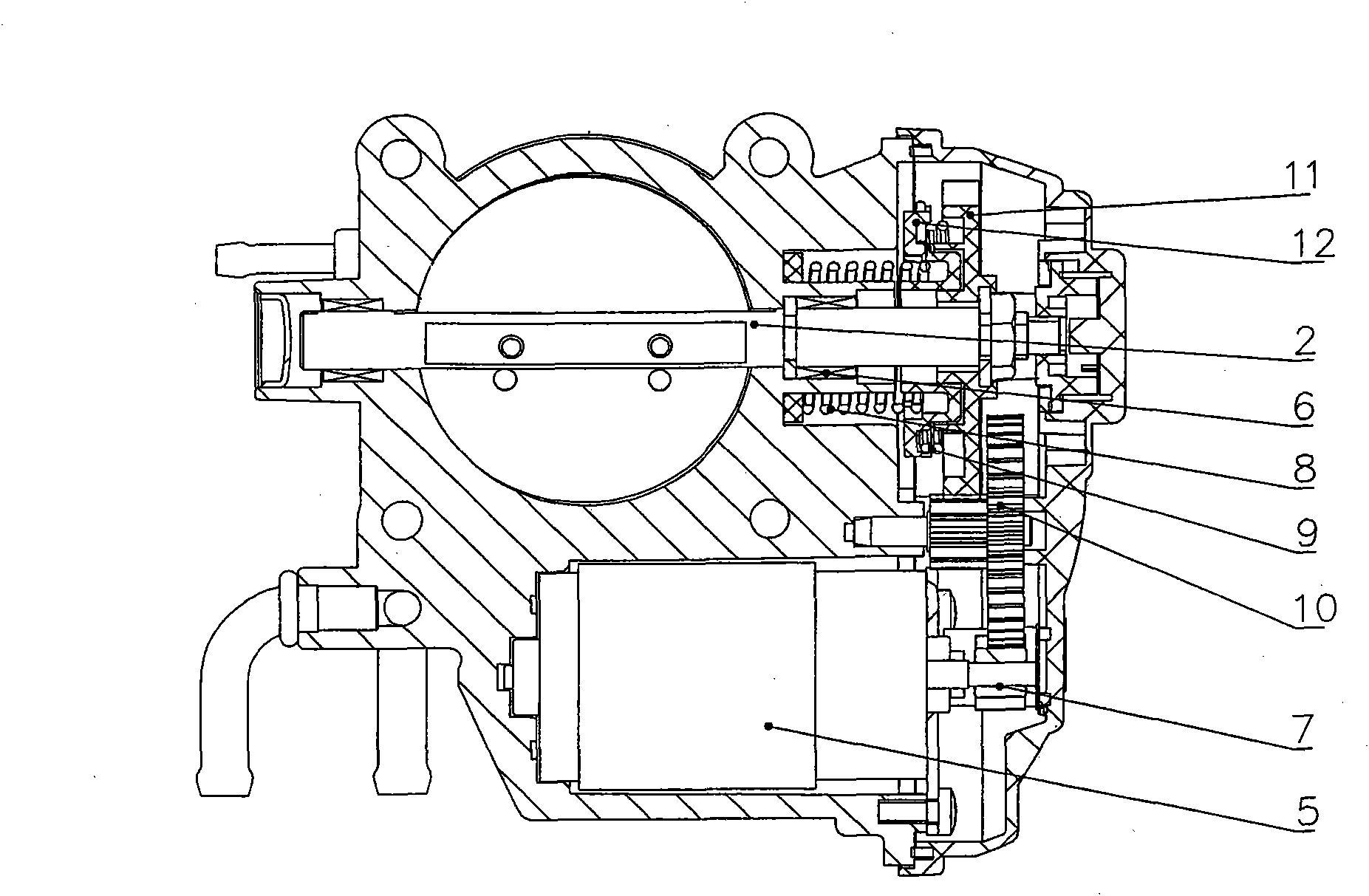

[0018] figure 2, image 3 Shown, the present invention mainly consists of throttle body 1, throttle valve plate 3, throttle shaft 2 (installed on the body through bearing 6), sensor assembly 4, motor assembly (including DC motor 5), intermediate gear, sector gear assembly It is composed of torsion spring and return torsion spring.

[0019] The crankcase ventilation pipe 13, the carbon tank pipe 14 and the booster pipe 15 are respectively riveted on the throttle body and communicated with the throttle intake passage; the throttle valve plate 3 is installed on the throttle shaft 2 with a self-locking screw 17; A sector gear 11 is installed on the throttle shaft 2, and the motor gear 7 mounted on the motor shaft meshes with the intermediate gear 10 mounted on the body 1, and the intermediate gear meshes with the sector gear; the body is located at the rotation position of the sector gear. Two protruding limit stops; one end of the reset torsion spring 8 is fixed on the body, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com