Micro perforated panel with fibers passing through micropores and preparation method thereof

A micro-perforated plate and fiber technology, which is applied in the direction of sound-producing instruments and instruments, can solve the problems of insufficient sound absorption frequency band and poor absorption of the micro-perforated plate sound absorber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

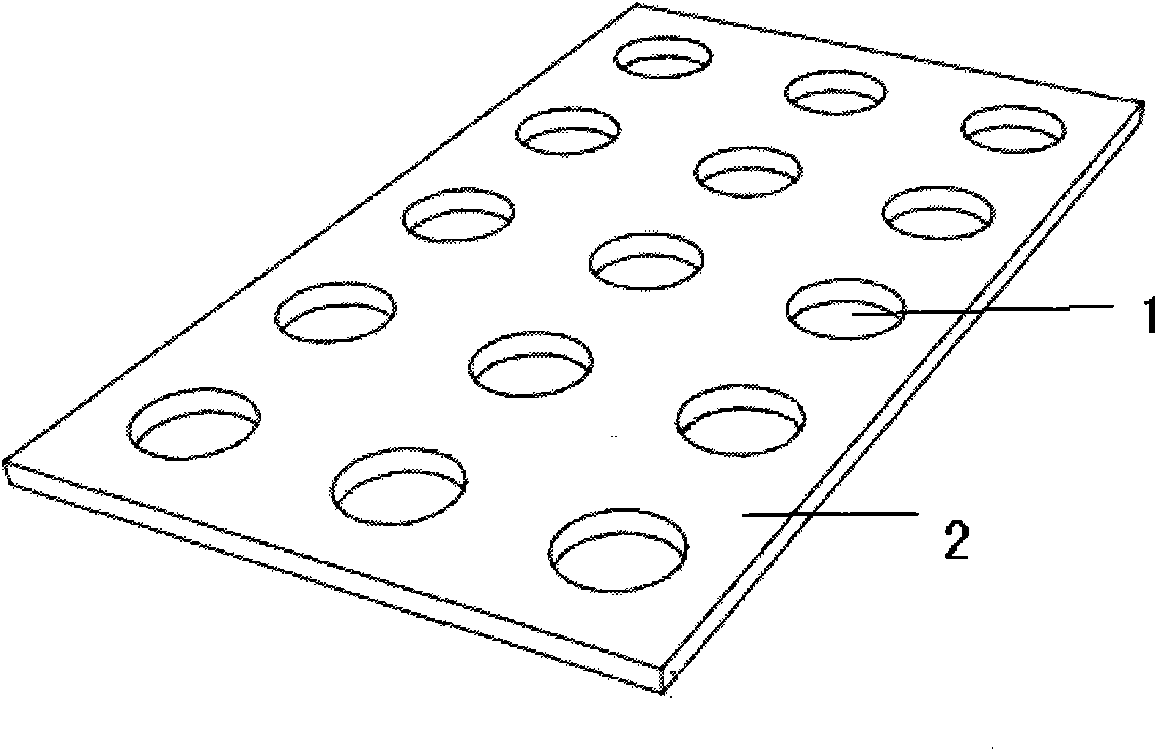

Embodiment 1

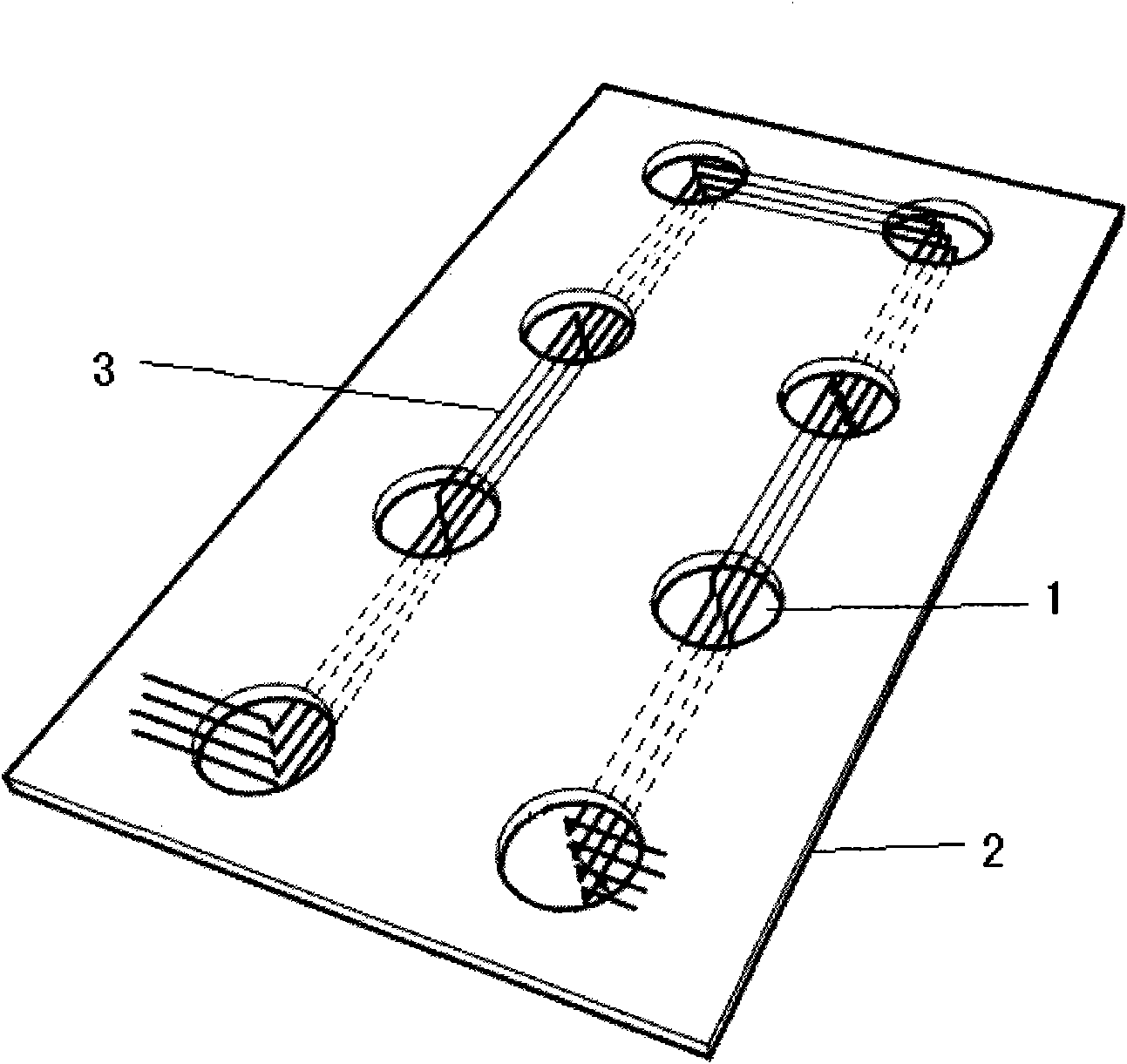

[0029] First of all, choose an ordinary plate, which can be a flat or curved plate, and the material is not limited. The thickness is 1-500 mm, and the micro-perforated plate is prepared with millimeter-scale micro-holes. Then, penetrate the fibers in the micropores of the micro-perforated plate, the fiber diameter ranges from 1 to 100 microns, the fiber penetration rate ranges from 1% to 100%, the fiber penetration amount ranges from 1% to 100%, and the fiber material is not limited . In this way, the perforated fiber microperforated plate was prepared. Its application is still the same as that of ordinary micro-perforated plates, and a certain air layer needs to be left behind as a resonant cavity.

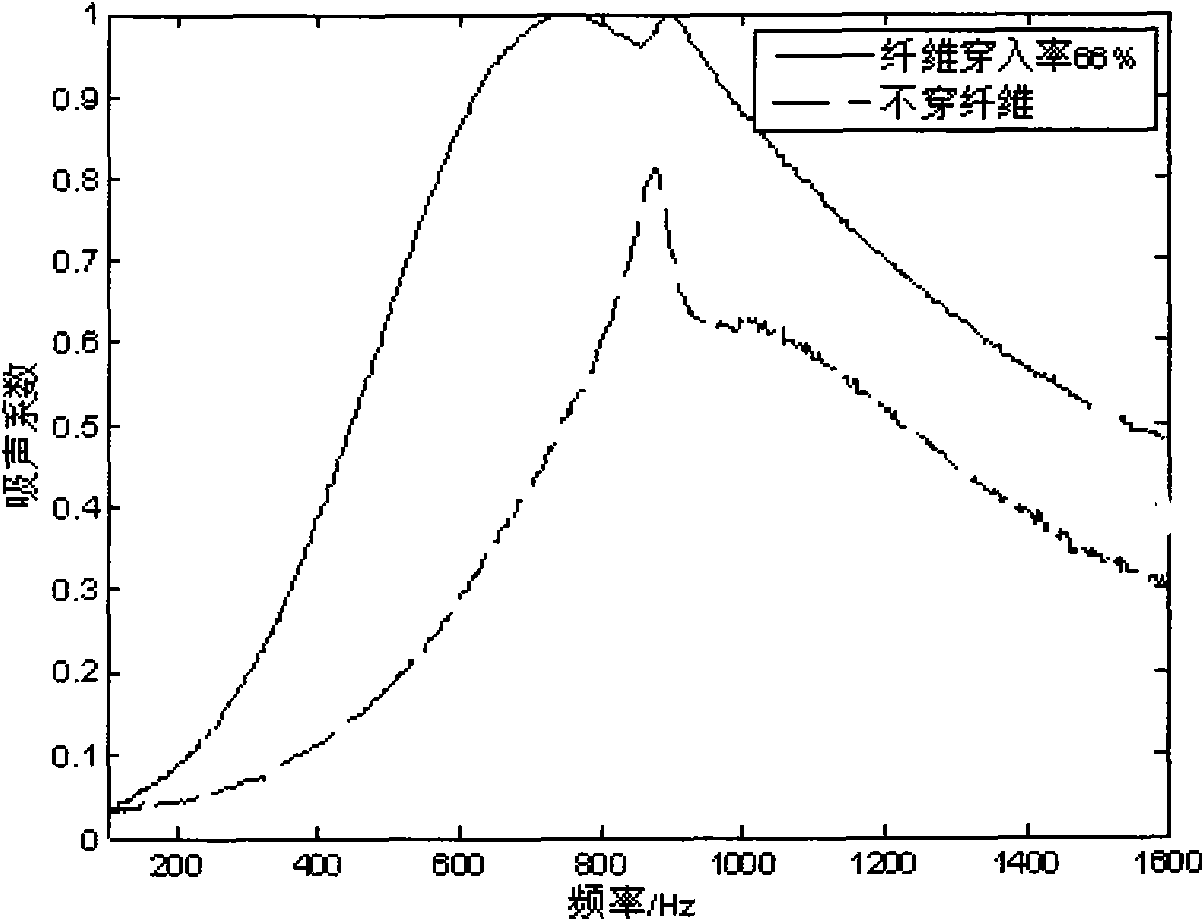

[0030] When the sound wave enters the micropores of the ordinary micro-perforated plate, it causes the friction between the air medium in the hole and the inner surface of the hole and consumes part of the sound energy.

Embodiment 2

[0032] (1) Preparation of the substrate

[0033] Take epoxy resin 128 and curing agent 593 in a ratio of 100:22; after stirring evenly, put it in a vacuum drying oven to evacuate to remove air bubbles;

[0034] Put the vacuumized material into ice water for cooling, about 15 minutes;

[0035] Pour the cooled material into the mold for casting; solidify at room temperature for 24 hours;

[0036] Remove the material from the mold.

[0037] The material of the substrate is not limited, and any material can be selected.

[0038] (2) Preparation of perforated fiber micro-perforated plate

[0039] The epoxy resin substrate obtained in (1) is made into a micro-perforated plate, and the parameters are:

[0040] Plate thickness: 4mm, hole diameter: 1mm, perforation rate: 7%, made into a micro-perforated plate. Penetration into wool fiber, penetration rate: 66.6%.

Embodiment 3

[0042] Method is with embodiment 2.

[0043] The parameters of the fiber perforated plate are as follows:

[0044] Board thickness: 2mm, hole diameter: 1mm, perforation rate: 6%, penetrate wool fiber, penetration rate: 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com