Powder cosmetic composition

一种组合物、固体化妆品的技术,应用在化妆品、化妆品、化妆品配制品等方向,能够解决蒸发过程漫长、不利微生物生长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0067] eye shadow

[0068] Exemplary powder eyeshadow compositions of the present invention having an interconnected base and cosmetic powder and having a multimodal distribution of particles are provided in Table 2.

[0069] Table 2

[0070]

[0071]

[0072] The powdered cosmetic compositions of Table 2 were prepared by mixing fillers, pigments (including pearlescent agents), binders, and preservatives to form a cosmetic powder premix. A wet premix was prepared by mixing a portion of the wet adhesive with the wax at a temperature of 85°C. Mix the cosmetic powder premix with the wet premix. Spray the wet premix over the powdered premix, mixing the two ingredients together. The mixture is then processed using a hammer mill. After this, the pearlescent agent and the remainder of the wet binder are added and mixed into a mixture.

[0073] The mixture was then gently pressed into a three-dimensional mold and heated in a convection oven at a temperature of 80°C for abou...

Embodiment II

[0075] eye shadow

[0076] Another eyeshadow composition of the present invention is provided in Table 3 having an interconnected matrix and a cosmetic powder with a multimodal particle distribution. Eye shadows can be made using the same method as described in Example 1 above.

[0077] table 3

[0078]

[0079]

Embodiment III

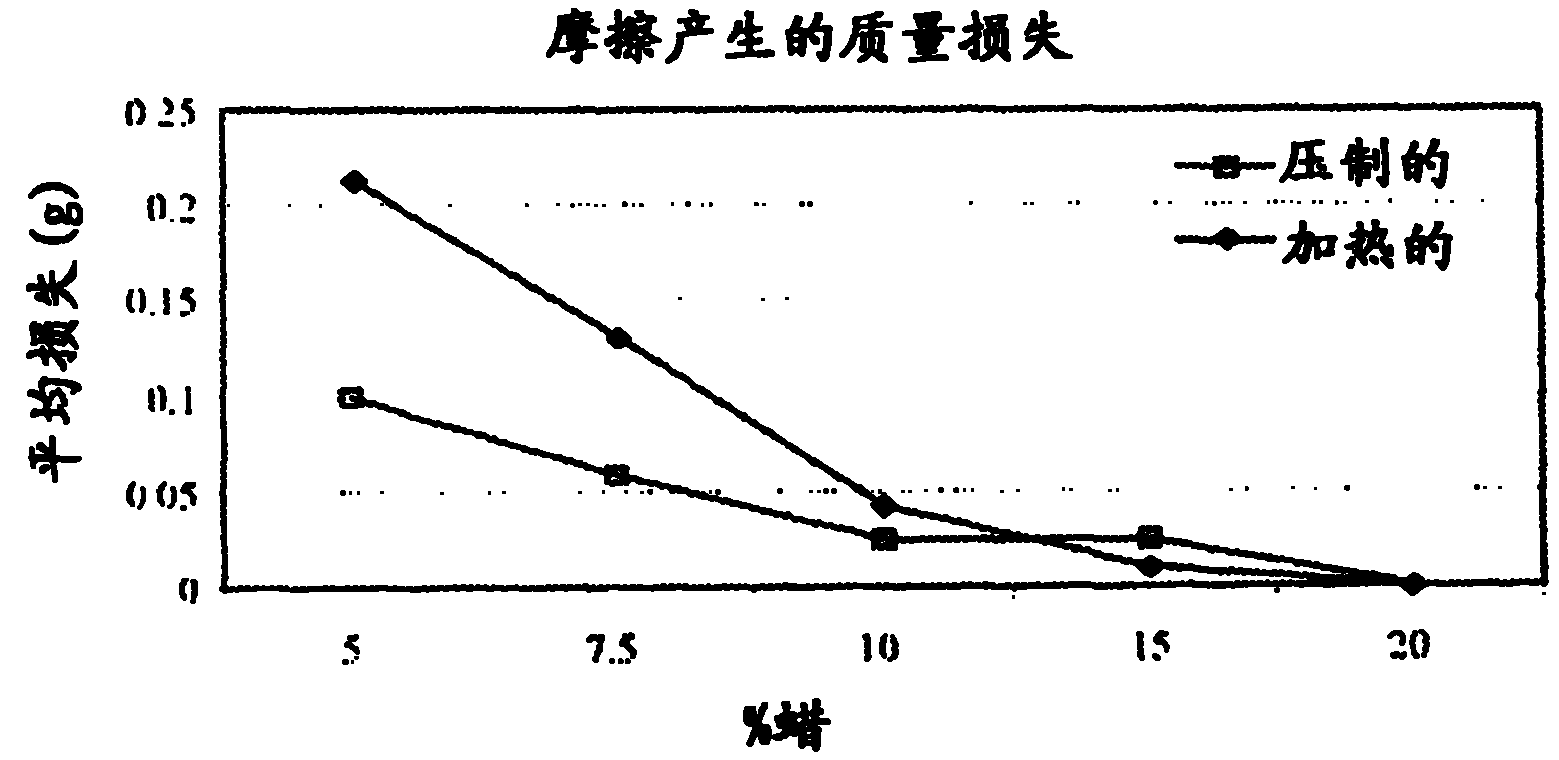

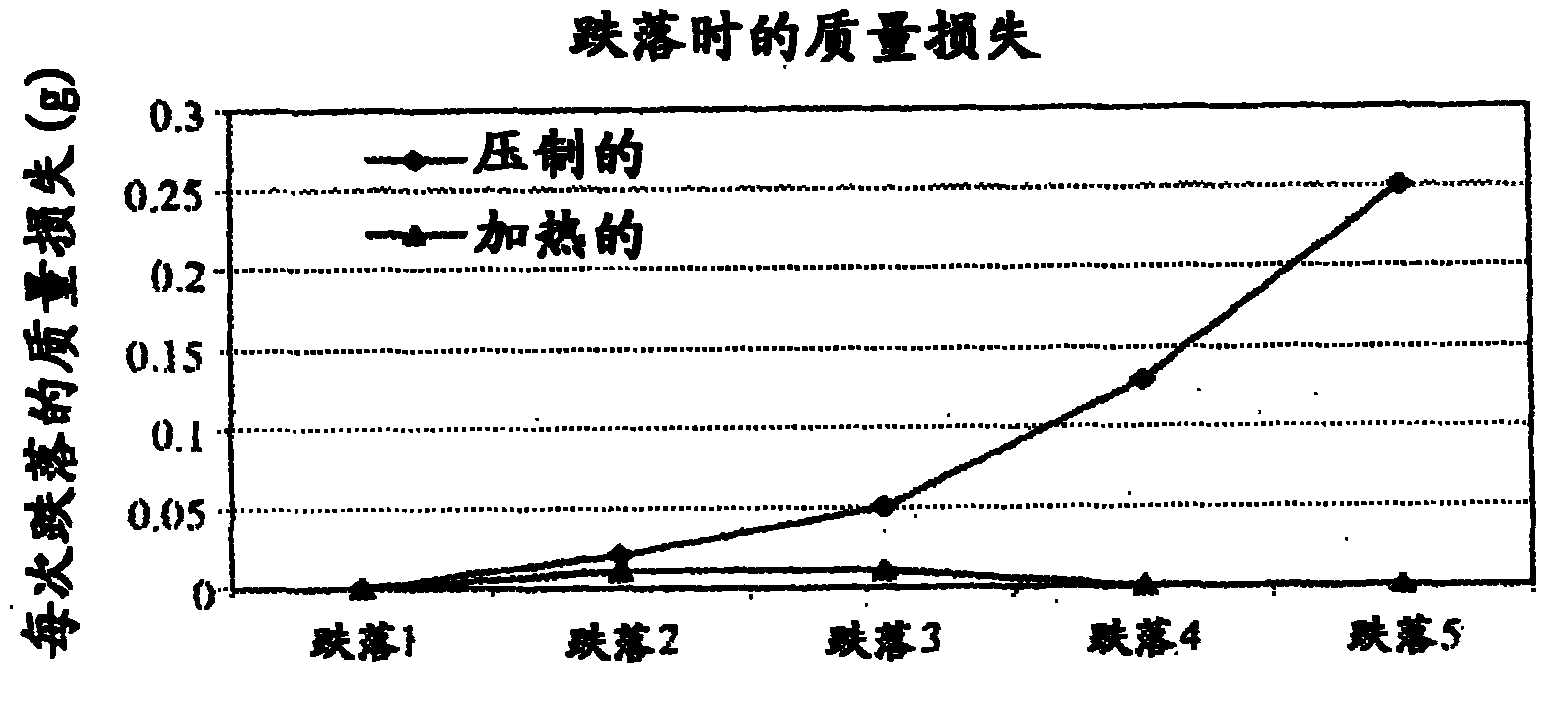

[0081] The spreadability of powdered cosmetic compositions made according to the invention was compared as a function of wax loading with that of conventionally pressed powdered cosmetics. Samples were prepared according to Formulations A-E by heating to a temperature sufficient to melt the wax or pressing the product in the absence of heat. The wax content ranged from 5% to 20% by weight, as shown in Table 4.

[0082] Table 4

[0083]

[0084] Smear effect test method

[0085] This method can be used to determine the spreadability or transferability of powder cosmetics. This test predicts the ability of the cosmetic composition to transfer to the applicator or finger during normal use of the cosmetic. The spreadability of the product is directly proportional to the amount of makeup removed by the applied shear force. Thus, the smudge effect can be expressed as a function of the amount of makeup lost after the rub test described herein.

[0086] First, the products wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com