Batter separator structures

一种铅酸蓄电池、基层的技术,应用在结构零件、铅酸蓄电池、电池组零部件等方向,能够解决厚度不一致等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will now be described with reference to the drawings, wherein like numerals indicate like features. The drawings show certain non-limiting embodiments of the invention. Figure 1a , 1b and 5 are not to scale and are not used for engineering drawings.

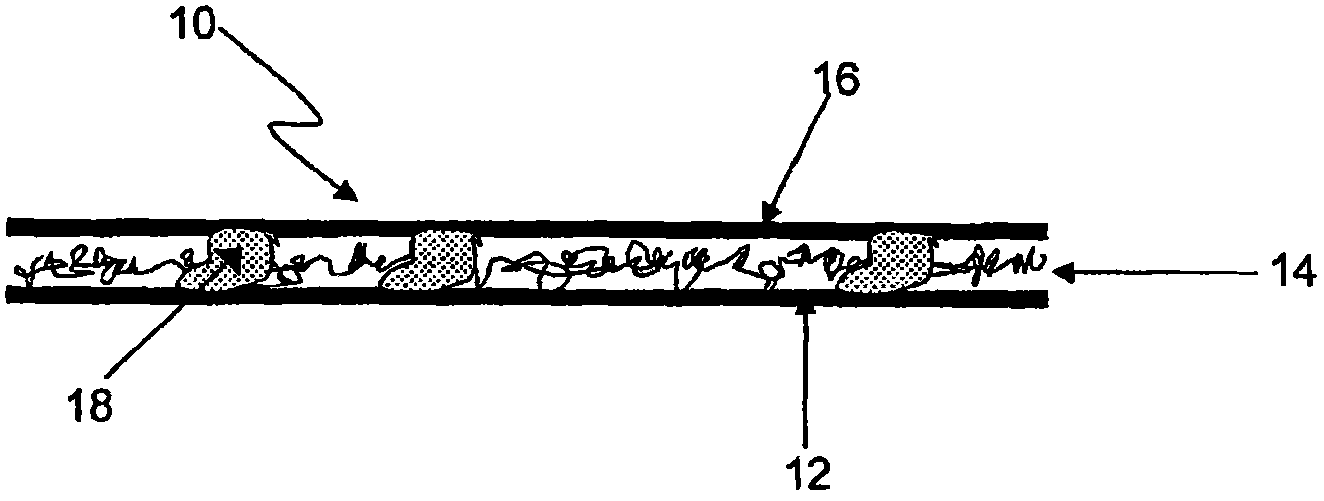

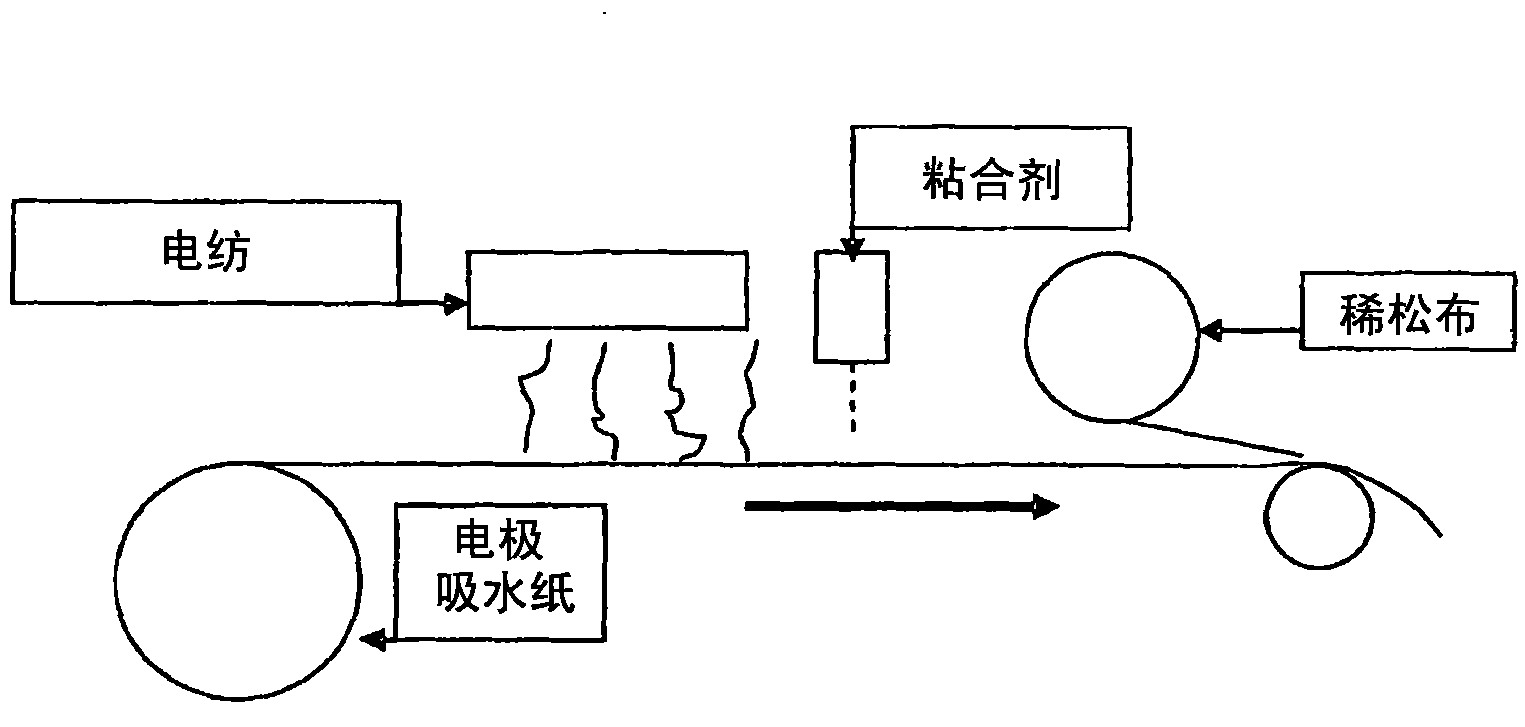

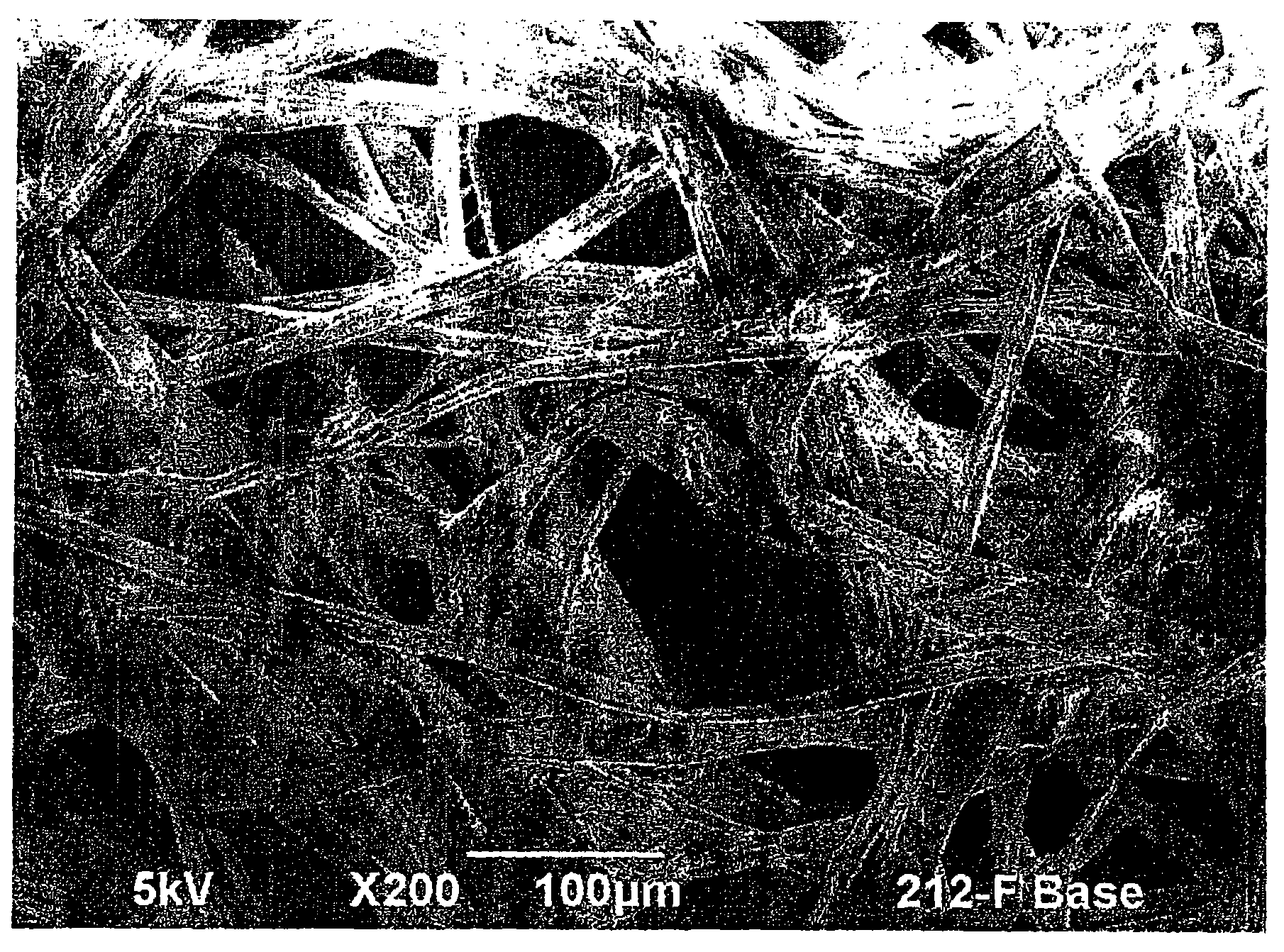

[0029] like Figure 1a As schematically shown in , the present invention provides a multilayer composite sheet suitable for use as a battery separator. In certain embodiments, as will now be discussed, the composite sheet can be used as a combined battery electrode blotter / separator. The composite sheet, shown generally at 10, includes a fibrous layer 12 on which is located a non-conductive polymeric nanofiber layer 14 and on layer 14 a polymeric scrim layer 16. In the case of this embodiment, said fibrous layer 12 is electrode absorbent paper. Discrete binder particles 18 bond the nanofibrous layer to both the paper layer and the scrim layer, thereby integrating the three layers to form the composite she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com