Enteric coated beta-mannase

A technology of mannanase and enteric coating, which is applied in the forming or processing of animal feed, animal feed, additional food elements, etc., and can solve the problem of undetectable enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Enteric coating treatment of embodiment 1.β-mannanase

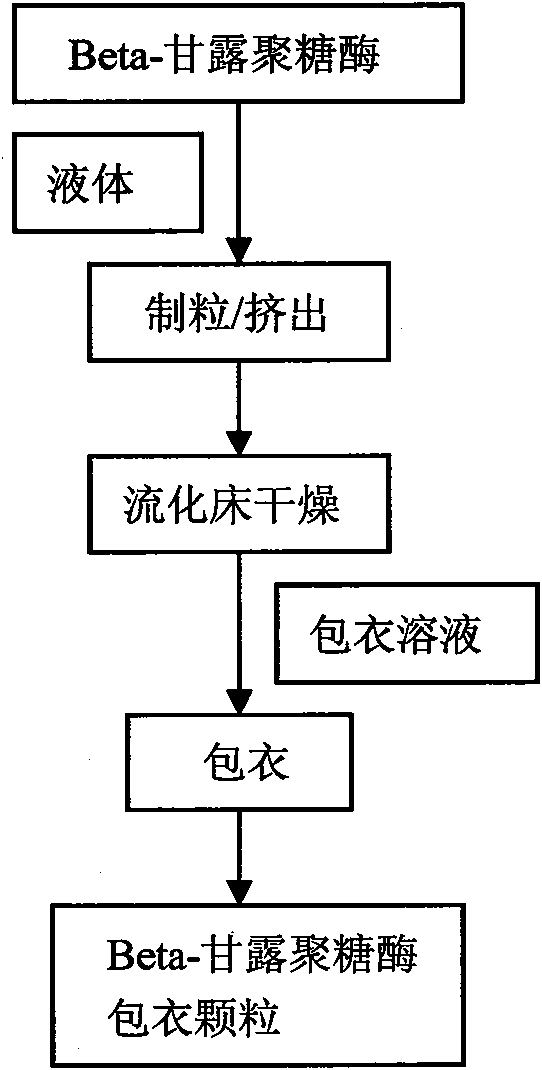

[0019] according to figure 1 Coated β-mannanase granules are prepared in the following steps, the first step being to form a compressible mixture which is then fed to a granulator / extruder to produce a compressed extrudate , after recovering the particles, they are dried in a fluidized bed.

[0020] 45% microcrystalline cellulose is mixed with refined β-mannanase, and the enzyme specific activity of β-mannanase is 15000U / mg. First rough mix in a closed weighing container, then place it in a mixer, slowly add cold water under mixing conditions to wet the homogeneous mixture to a water content of about 30%, and mix to form a wet mass.

[0021] The wet mass was then fed into the hopper of a granulator and granulated / extruded through a domed die at a screw speed of 50 rpm. The extrudate was placed in a spheronizer and spheronized for three minutes or until uniform granules were formed, the resulting wet granules wer...

Embodiment 2

[0024] The coated granules of the present invention were prepared according to the same process as in Example 1, except that the composition of the coating material was different.

[0025] Fluid bed dried β-mannanase granules 2500g

[0026] Coating material: liquid shellac 300ml

[0027] Corn Gluten Extract 250g

[0028] Glycerin 50ml

[0029] 90% ethanol 200ml

Embodiment 3

[0031] The coated granules of the present invention were prepared according to the same process as in Example 1, except that the composition of the coating material was different.

[0032] Fluid bed dried β-mannanase granules 2500g

[0033] Coating material: corn protein extract 300g

[0034] Glycerin 50ml

[0035] 90% ethanol 550ml

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com