Method for preventing polymerization of aromatic olefin monomers in storage process

A technology for aromatic olefins and monomers, which is used in the field of preventing polymerization of styrene monomers during storage. It can solve the problems of no reported changes in the adhesion of polymerization inhibitor coatings, coating brushing methods, etc., and prolong the period of cleaning tanks for maintenance. , solve the aggregation phenomenon, and improve the effect of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0026] On the standard tinplate (50×100×0.2~0.3mm), use three-layer overcoating, double-layer overcoating, and single-layer painting respectively to paint epoxy resin paint. The amount of polymerization inhibitor TBC accounts for the amount of paint 4% (mass, the same below), wherein the thickness of the bottom layer is about 40 μm, the middle layer is about 80 μm, and the surface layer is about 100 μm. After the coating was dry, the adhesion was tested, and then the coated panel was placed in a 5L styrene storage tank and soaked at 30°C for 3 months. The results are shown in Table 1.

[0027] Table 1 Variation of coating adhesion with different brushing methods

[0028] Example

[0029] It can be seen from Table 1 that the three-layer overcoating method improves the compatibility between the polymerization inhibitor and the coating, and the adhesion is significantly better than the single-layer and double-layer coating methods.

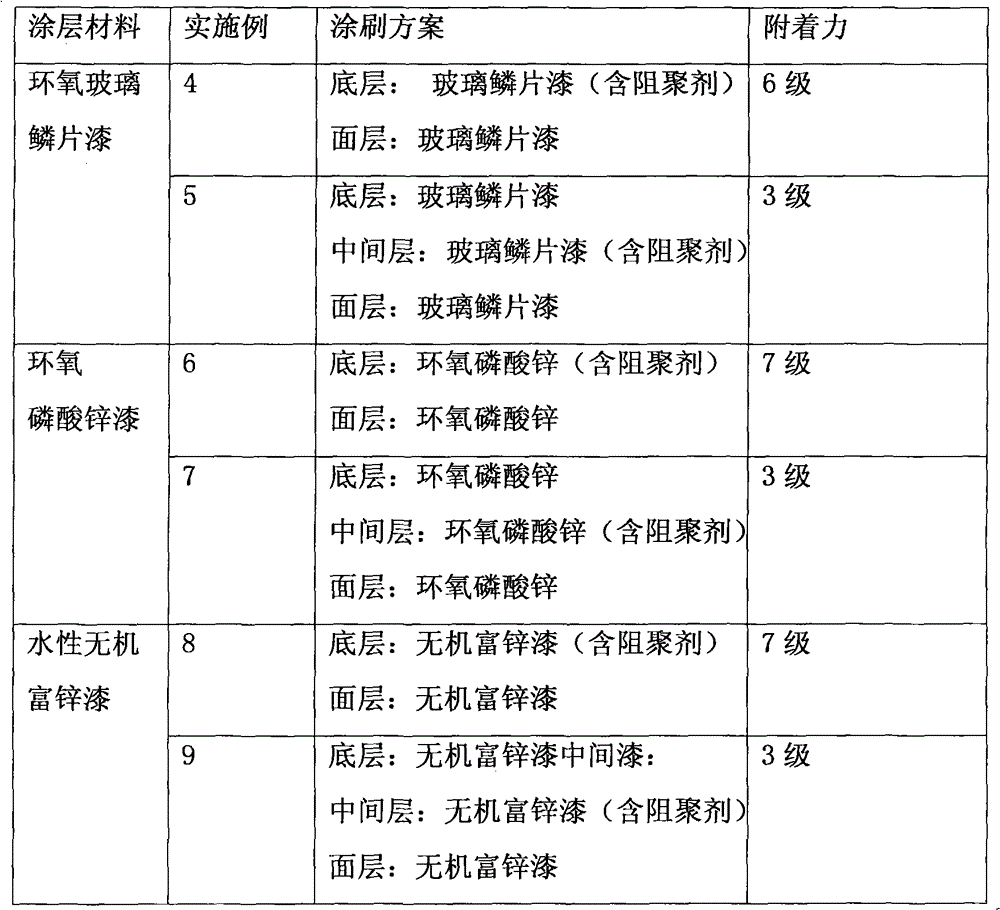

Embodiment 4~9

[0031] On the tinplate plates described in Examples 1 to 3, different paints and brushing methods were used to paint, and the amount of polymerization inhibitor TBC accounted for 2% of the paint amount. The changes in coating adhesion are shown in Table 2.

[0032] Table 2 Variation of adhesion of different coatings

[0033]

[0034] It can be seen from Table 2 that no matter what kind of paint, after adding the polymerization inhibitor, the suitable brushing method is three-layer overcoating. After the above-mentioned coated panels were soaked in styrene for a period of time, the coatings of Examples 5, 7, and 9 were intact without peeling; the coatings of Examples 4, 6, and 9 all fell off in varying degrees.

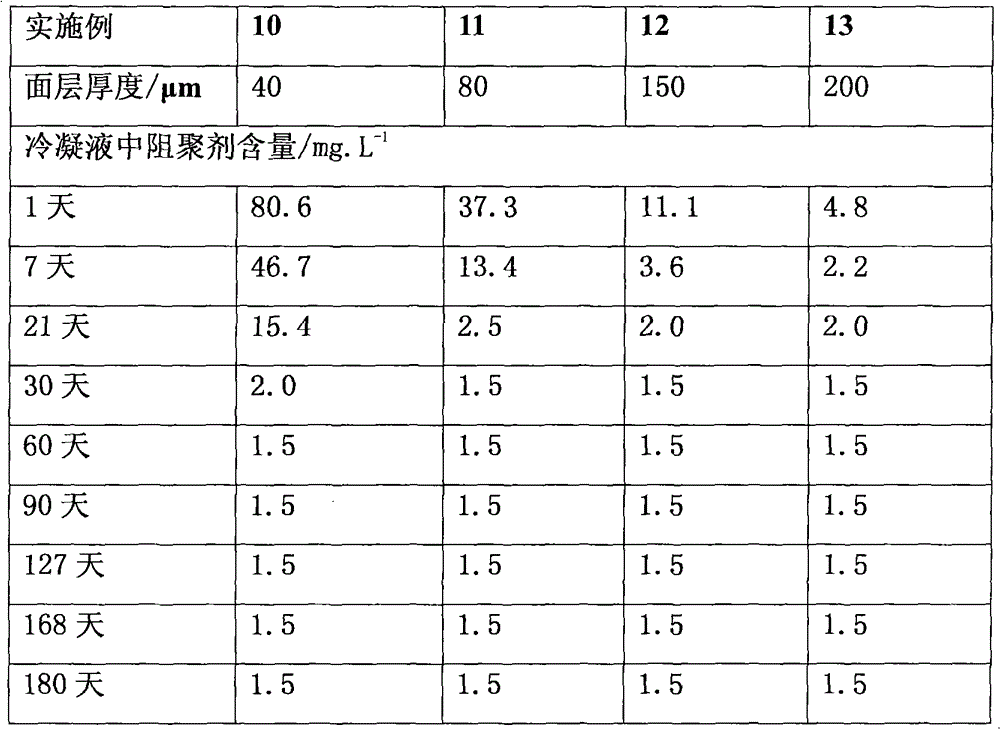

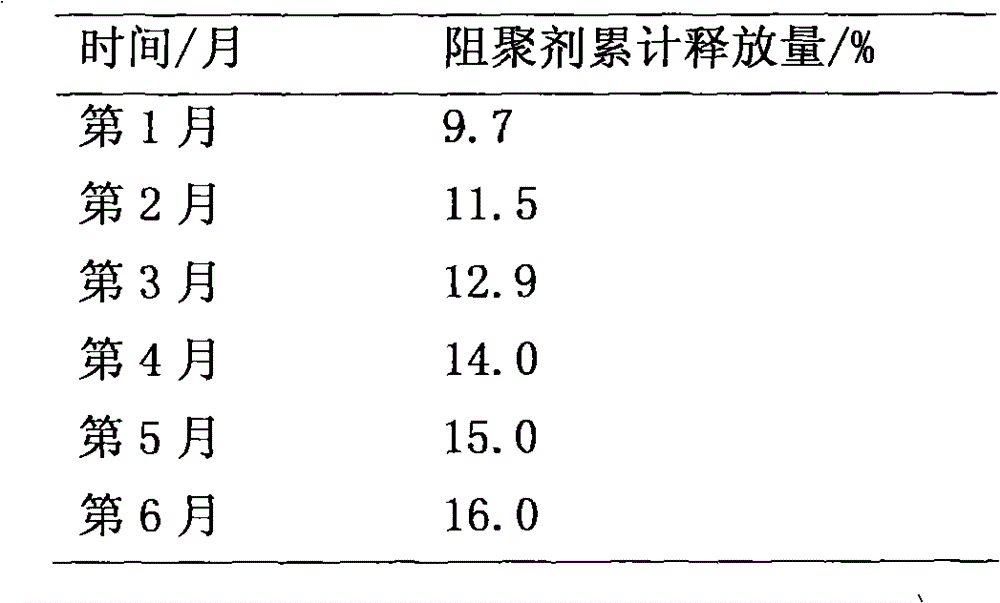

Embodiment 10~13

[0036] On the basis of the overcoating method in Example 3, epoxy resin coatings were applied to the inner wall of the roof of a 5 L styrene storage tank according to different surface layer thicknesses, and the amount of TBC added accounted for 4% of the coating amount. Under the storage temperature of 40°C, the styrene condensate was collected regularly, and the content of polymerization inhibitor was analyzed. The results are shown in Table 3.

[0037] Table 3 Changes of inhibitor content in condensate under different topcoat thicknesses

[0038]

[0039] It can be seen from Table 3 that by changing the thickness of the surface layer, the release rate of the polymerization inhibitor can be better controlled, and the coating can be maintained for a longer polymerization inhibition time, reflecting the expected effect.

[0040] If no polymerization inhibitor is added to the coating, polymers will appear on the top of the tank and adhere to the inner wall under the same con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com