Epoxy asphalt deck crack repairing agent capable of being cured at normal temperature

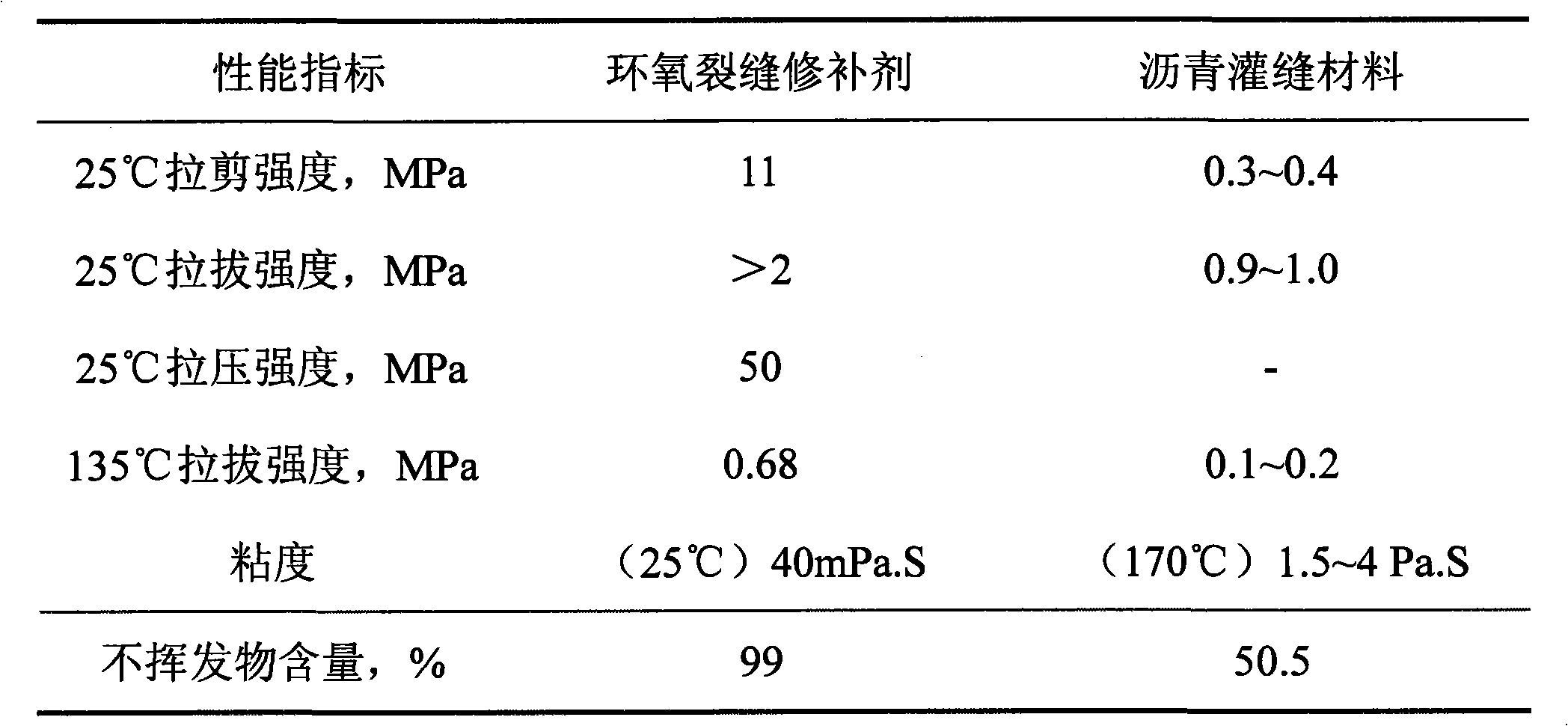

An epoxy asphalt, room temperature curing technology, used in bridge maintenance, bridges, bridge parts, etc., can solve problems such as weak bonding, and achieve the effects of stable performance, good high temperature flow resistance, and good chemical corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 1) Prepare two mixtures of A and B

[0012] a. Preparation of Type A mixture is prepared according to the following parts by weight: 30 parts of bisphenol epoxy resin, 2 parts of toughening agent and 7 parts of epoxy reactive diluent, and the above-mentioned components are mixed at room temperature to form Type A mixture.

[0013] b. Prepare Type B mixture according to the following parts by weight: 90 parts of 203 modified amine curing agent, 1 part of DMP-30 curing accelerator, 1 part of organosiloxane coupling agent KH-5501. Mix separately to form a mixture B.

[0014] 2) Preparation of crack repair agent

[0015] The above-prepared Type A mixture and Type B mixture were prepared by weight according to a weight ratio of 3:1, and then stirred and mixed to obtain the crack repair agent of this embodiment.

Embodiment 2

[0017] 1) Prepare two mixtures of A and B

[0018] a. Type A mixture includes the following components in parts by weight: 40 parts of 618 bisphenol A epoxy resin, 6 parts of CYH-277 reactive toughening agent and 3 parts of epoxy reactive diluent. Mix separately to form a mixture.

[0019] b. Type B mixture includes the following components in parts by weight: 100 parts of 203 modified amine curing agent, 2 parts of DMP-30 curing accelerator, 2 parts of KH-550 organosiloxane coupling agent. The components are mixed to form the B mixture.

[0020] 2) Preparation of crack repair agent

[0021] The above-prepared Type A mixture and Type B mixture were weight-proportioned and mixed at a weight ratio of 3:1 to prepare the crack repair agent of this embodiment.

Embodiment 3

[0023] In this embodiment, the weight proportions of the components of the A mixture and the B mixture are slightly different, and the other preparation processes are the same, as follows:

[0024] 1) Prepare two mixtures of A and B

[0025] a. Type A mixture includes the following components in parts by weight: 35 parts of 618 bisphenol epoxy resin, 4 parts of CYH-277 reactive toughening agent and 5 parts of epoxy reactive diluent. Mix to form a mixture.

[0026] b. Type B mixture includes the following components in parts by weight: 95 parts of 203 modified amine curing agent, 1 part of DMP-30 curing accelerator, 2 parts of KH-550 organosiloxane coupling agent. The components are mixed to form the B mixture.

[0027] 2) Preparation of crack repair agent

[0028] Carry out the weight proportioning and mixing of the above-mentioned prepared A mixture and B mixture in a weight ratio of 3:1

[0029] Mix to prepare the crack repair agent of this embodiment.

[0030] The DMP-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com