Method for intermittently preparing biodiesel from camphor tree seed kernel oil through ultrasonic reaction pot

A technology of camphor tree seed oil and ultrasonic reaction, which is applied in biofuels, biological raw materials, petroleum industry, etc., can solve the problems affecting the oxidation stability of biodiesel, difficulty in methanol separation, and slow reaction rate, so as to reduce the dosage ratio and shorten the The effect of speeding up reaction time and reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

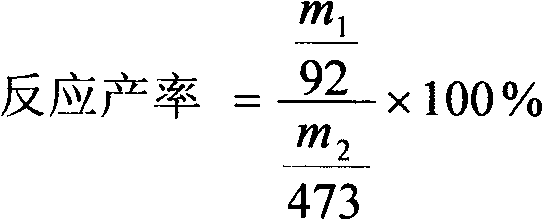

Examples

Embodiment 1

[0026] (1) Preparation of camphor tree seed oil. The camphor tree seeds are firstly removed from the impurities, peeled and shelled to obtain the camphor tree seed kernels, and then the camphor tree seed kernels are extracted with No. 6 solvent oil to obtain the camphor tree seed kernel oil.

[0027] (2) Transesterification of camphor tree seed kernel oil with methanol. Add methanol and camphor tree seed oil in the ultrasonic reaction tank according to the molar ratio of methyl alcohol: camphor tree seed oil=3:1, then add catalyst sodium methylate to the ultrasonic reaction tank by 0.01% of the camphor tree seed oil quality to obtain the mixture , heating the mixture to a temperature of 20°C; then turn on the ultrasonic irradiation device, the ultrasonic frequency is 16kHz, the ultrasonic power is 50W, and the ultrasonic sound intensity is 300W / cm 2 , the reaction time of ultrasonic irradiation is 30min, then stop, and after the product is allowed to stand for stratification,...

Embodiment 2

[0034] (1) Preparation of camphor tree seed oil. Camphor tree seeds are removed, peeled, and shelled to obtain camphor tree seed kernels, and then the camphor tree seed kernels are pressed to obtain camphor tree seed kernel oil.

[0035](2) Transesterification of camphor tree seed kernel oil with methanol. Add methanol and camphor tree seed oil in the ultrasonic reaction tank according to the molar ratio of methyl alcohol: camphor tree seed oil=8:1, then add catalyst NaOH to obtain the mixture in the ultrasonic reaction tank by 0.3% of the camphor tree seed oil quality, Heat the mixture to a temperature of 50°C; then turn on the ultrasonic irradiation device, the ultrasonic frequency is 100kHz, the ultrasonic power is 1000W, and the ultrasonic sound intensity is 1000W / cm 2 , the reaction time of ultrasonic irradiation is 10min, then stop, and after the product is allowed to stand for stratification, the upper layer mixture is distilled out of methanol under normal pressure or...

Embodiment 3

[0038] (1) Preparation of camphor tree seed oil. The camphor tree seeds are firstly removed from the impurities, peeled and shelled to obtain the camphor tree seed kernels, and then the camphor tree seed kernels are extracted with No. 6 solvent oil to obtain the camphor tree seed kernel oil.

[0039] (2) Transesterification of camphor tree seed kernel oil with methanol. Add methanol and camphor tree seed kernel oil in the ultrasonic reaction tank according to the ratio of methanol: camphor tree seed kernel oil=15:1, and then add catalyst K by 1% of the camphor tree kernel oil quality 2 CO 3 Get the mixture in the ultrasonic reaction tank, heat the mixture to a temperature of 70°C; then turn on the ultrasonic irradiation device, the ultrasonic frequency is 45kHz, the ultrasonic power is 5000W, and the ultrasonic sound intensity is 10000W / cm 2 , the reaction time of ultrasonic irradiation is 20min and then stop. After the product is allowed to stand and stratify, the upper lay...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap