Method for controlling coal injecting rate of blast furnace

A rate control, blast furnace coal injection technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of lag, lag, and damaged furnace conditions in the injection rate, to prevent lag and large fluctuations, and enhance self-adaptation. ability, avoid the effect of large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

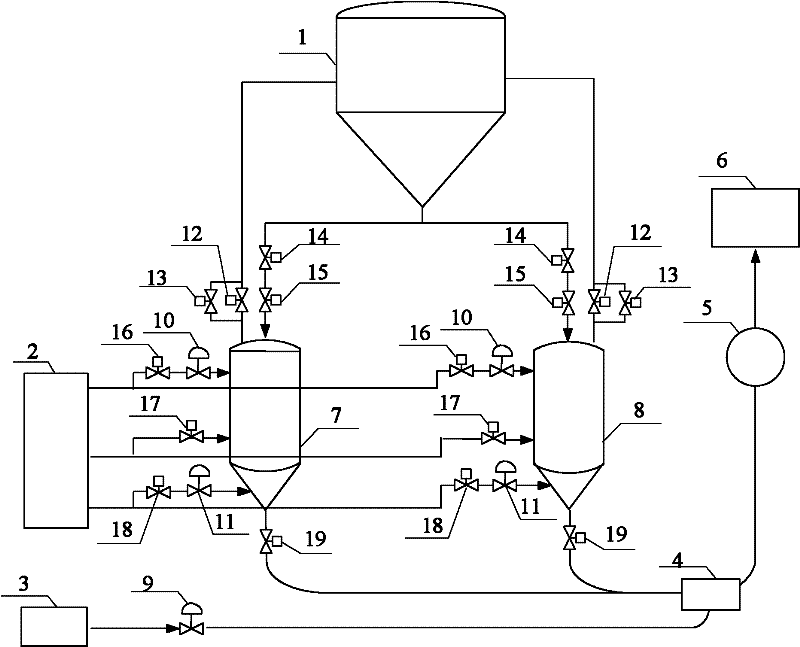

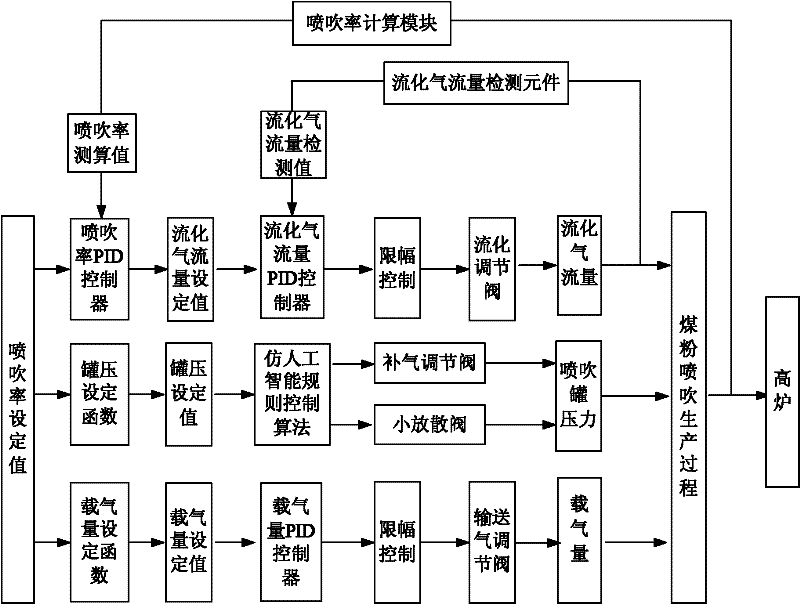

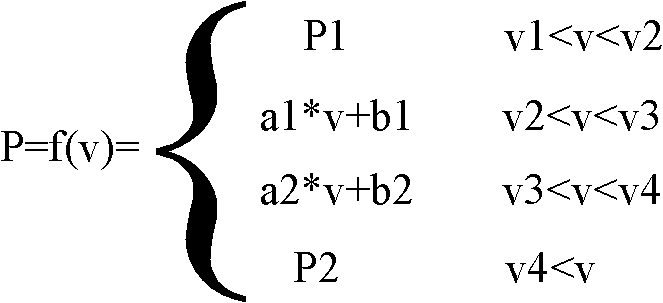

[0029] For the control method of blast furnace coal injection injection rate provided by the present invention, see figure 1 , using more than two tanks (including two tanks) in parallel injection mode, the adjustment of the injection rate is mainly achieved by adjusting the air supply control valve, small release cut-off valve, fluidization control valve and conveying gas control valve. The air supply regulating valve and the small release cut-off valve are used to stabilize the pressure of the blowing tank, and the regulating valve of the conveying gas is used to stabilize the carrier gas volume. Blowing rate, if the relationship between the three variables of tank pressure, carrier gas volume and fluidizing gas flow and the blowing rate can be well handled, then the blowing rate can be effectively controlled to create conditions for the smooth production of the blast furnace.

[0030] The method provided by the present invention will be further described below in conjunctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com