Automobile engine camshaft

A technology for automobile engines and camshafts, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as high cost, difficulty in arranging and processing lubricating oil passages, and difficulty in machining, so as to reduce weight and structure Compact, Difficult-Reducing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

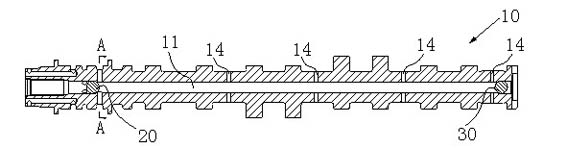

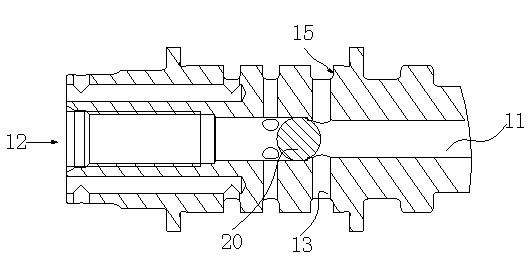

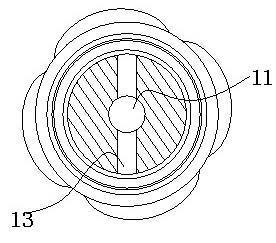

[0009] like figure 1 , a camshaft of an automobile engine, the camshaft 10 is arranged in the axial direction

[0010] There is a main oil passage 11, and the main oil passage 11 located at the first journal of the camshaft 10 is provided with a partition 20 that divides the main oil passage 11 into an open cavity 11a and a closed cavity 11b, and the camshaft 10 with the open cavity 11a An oil passage 12 communicating with the phaser is provided on the top, an oil inlet 13 communicating with the main oil passage 11 is provided at the first journal of the closed cavity 11b, and an oil inlet 13 communicating with the main oil passage 11 is provided at the journal of the camshaft 10 that cooperates with the remaining bearing caps. There is an auxiliary oil passage 14 communicating with the main oil passage 11. The oil inlet hole 13 corresponds to the oil passage on the first bearing cap. After lubricating oil is introduced into the first bearing cap from the cylinder head, it fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com