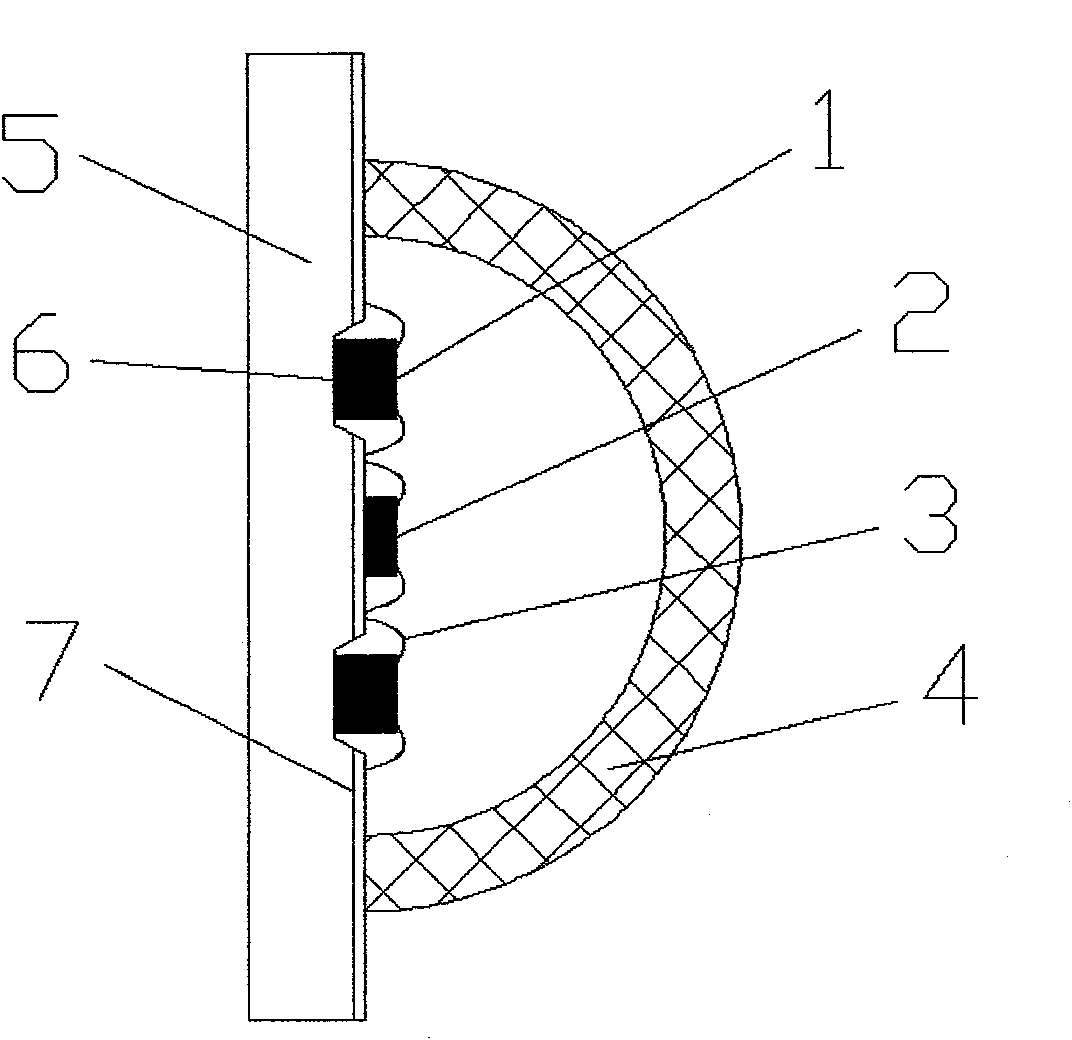

High-power LED surface light source

An LED light source, high-power technology, applied in the field of new light sources, can solve the problems of white LED manufacturing process defects, low color rendering index, "yellow circle", etc., to improve the color rendering effect and luminous efficiency, increase the heat dissipation area, and speed up the heat dissipation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

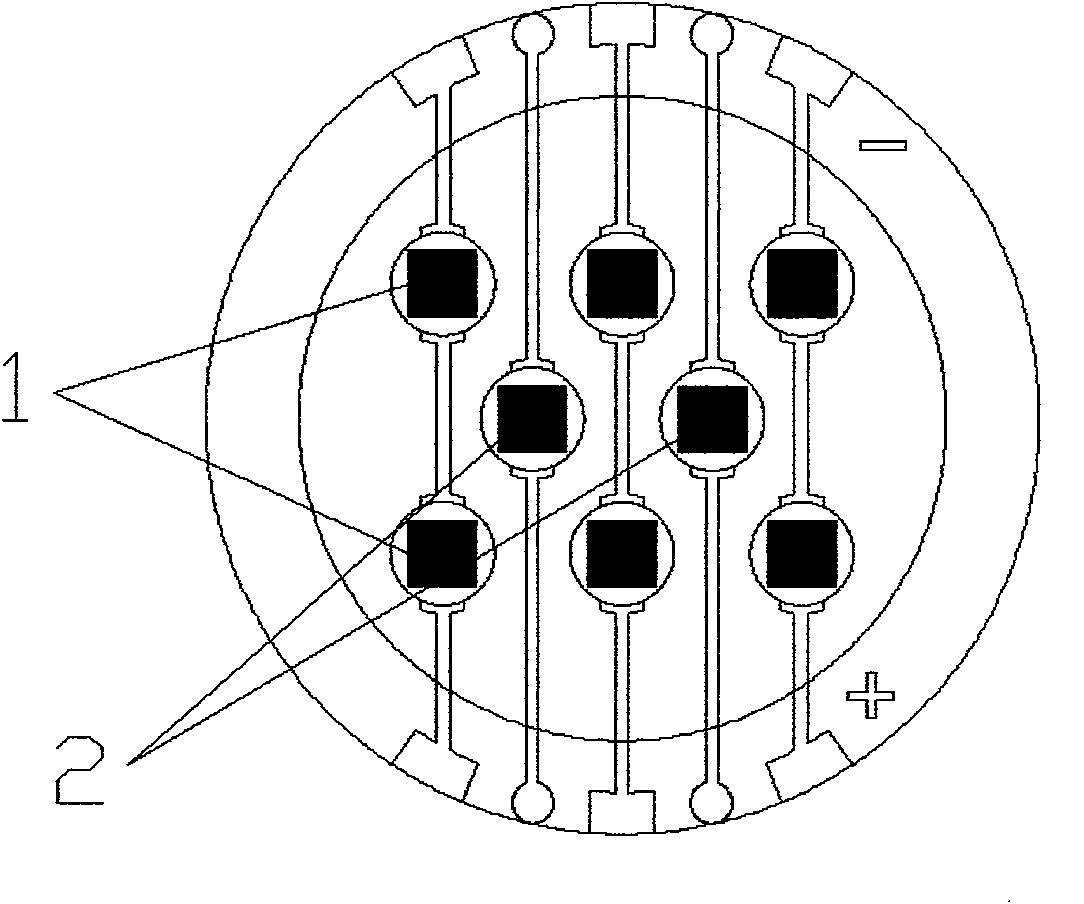

[0016] Example 1, such as figure 2 When the wavelength of the red LED2 is 620nm and the ratio of the white LED1 to the red LED2 is 3:1, the color temperature of the light source is controlled at 3000K±20K, the color rendering index is 90, and the luminous efficiency is 90lm / W.

Embodiment 2

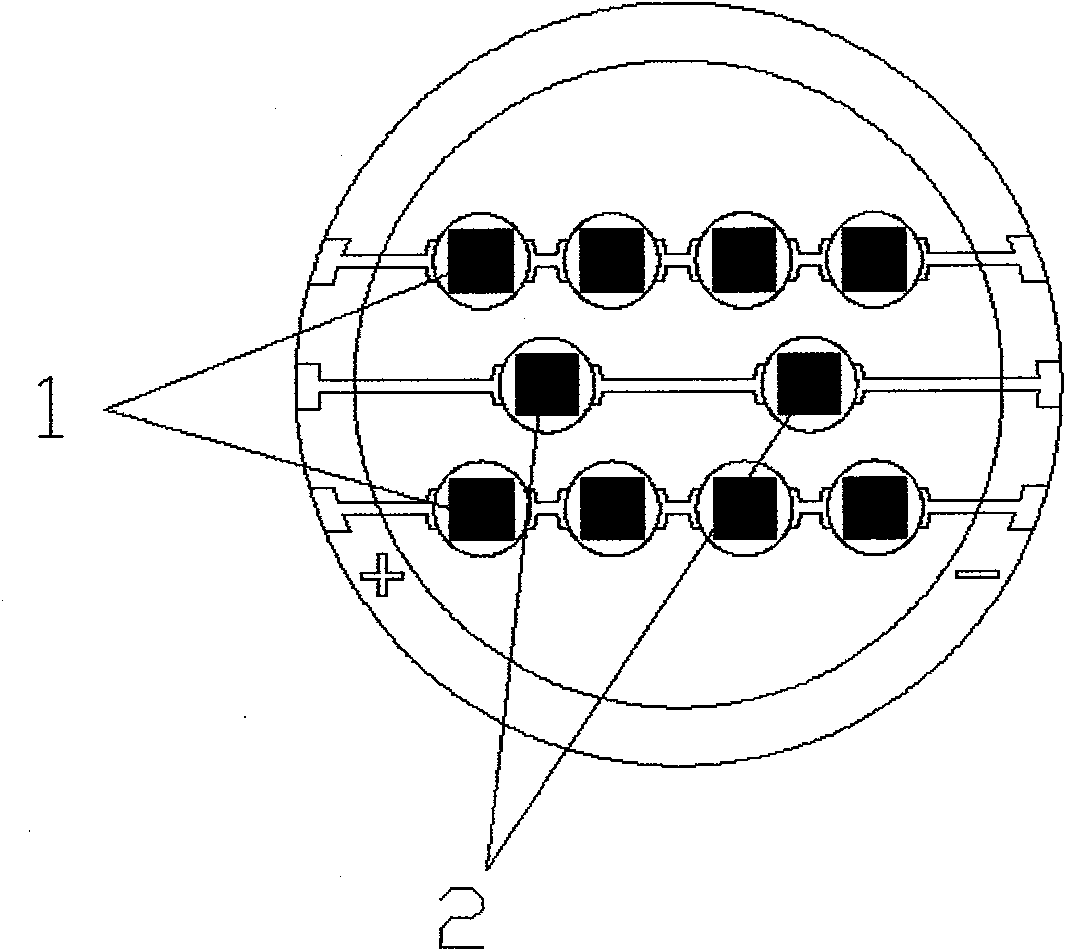

[0017] Example 2, such as image 3 When the wavelength of red LED2 is 640nm and the ratio of white LED1 to red LED2 is 4:1, the color temperature of the light source is controlled at 2900K±20K, the color rendering index is 95, and the luminous efficiency is 95lm / W.

Embodiment 3

[0018] Example 3, such as Figure 4 When the wavelength of red LED2 is 660nm and the ratio of white LED1 to red LED2 is 5:1, the color temperature of the light source is controlled at 2800K±20K, the color rendering index is 98, and the luminous efficiency is 100lm / W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com