Large circulating fluidized bed unit cooperative control device based on intensified combustion

A circulating fluidized bed and coordinated control technology, which is applied to the fuel, combustion type, and fluidized bed combustion equipment burning in the melting state. Large inertia and other problems, to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

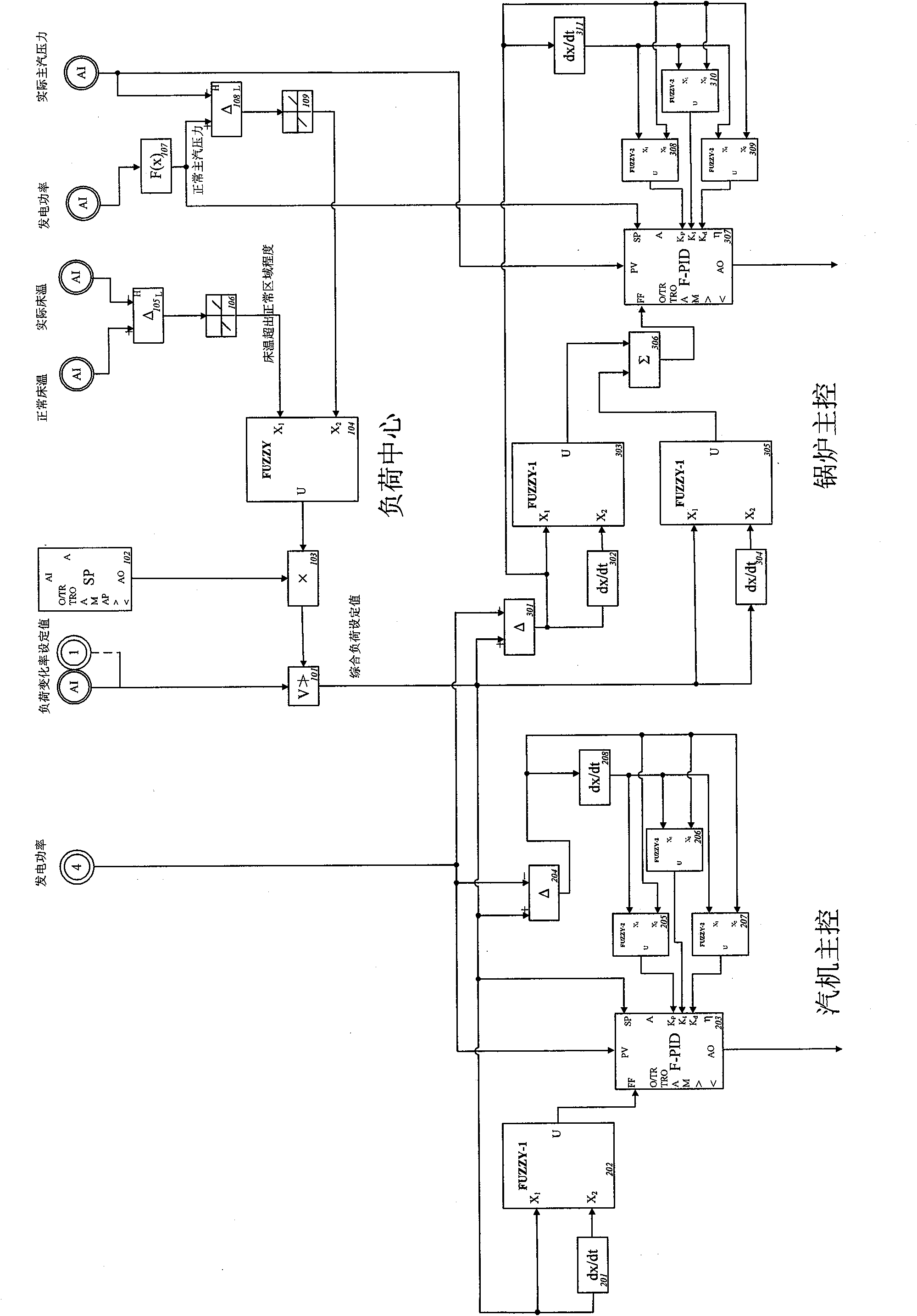

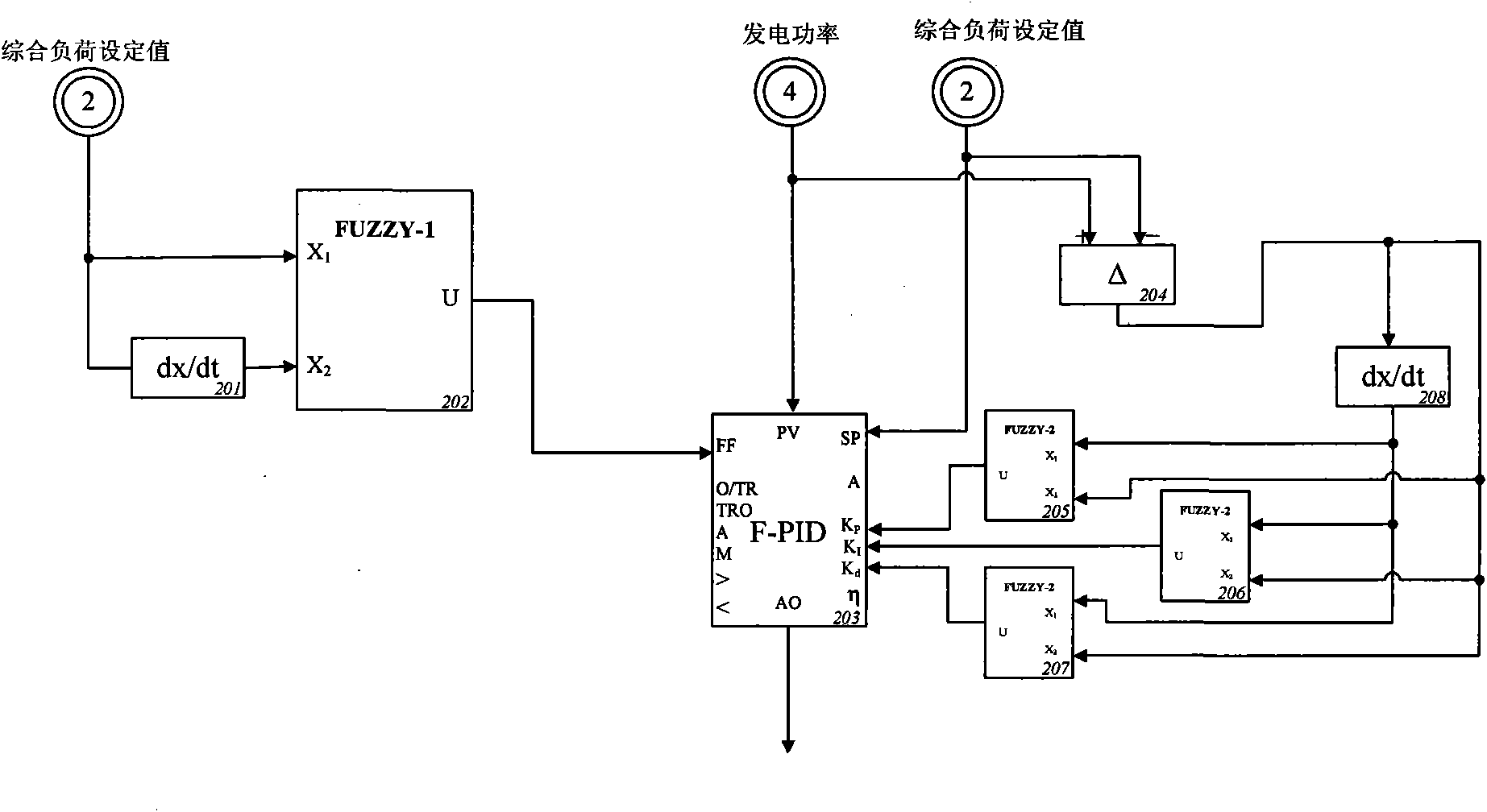

[0036] Take the 1025t / h circulating fluidized bed boiler as an example below to further illustrate the present invention, see Figure 1 to Figure 4 . The boiler adopts a single furnace structure without an external heat exchanger, and the composition of the main control circuit is shown in figure 1 , which is based on the enhanced combustion circulating fluidized bed unit coordination control device, including the load control center circuit, the main control circuit of the steam turbine and the main control circuit of the boiler.

[0037] This example is developed on the platform of distributed control system (DCS), and adopts the control structure combining fuzzy feedforward control and feedback control of fuzzy self-adjusting PID.

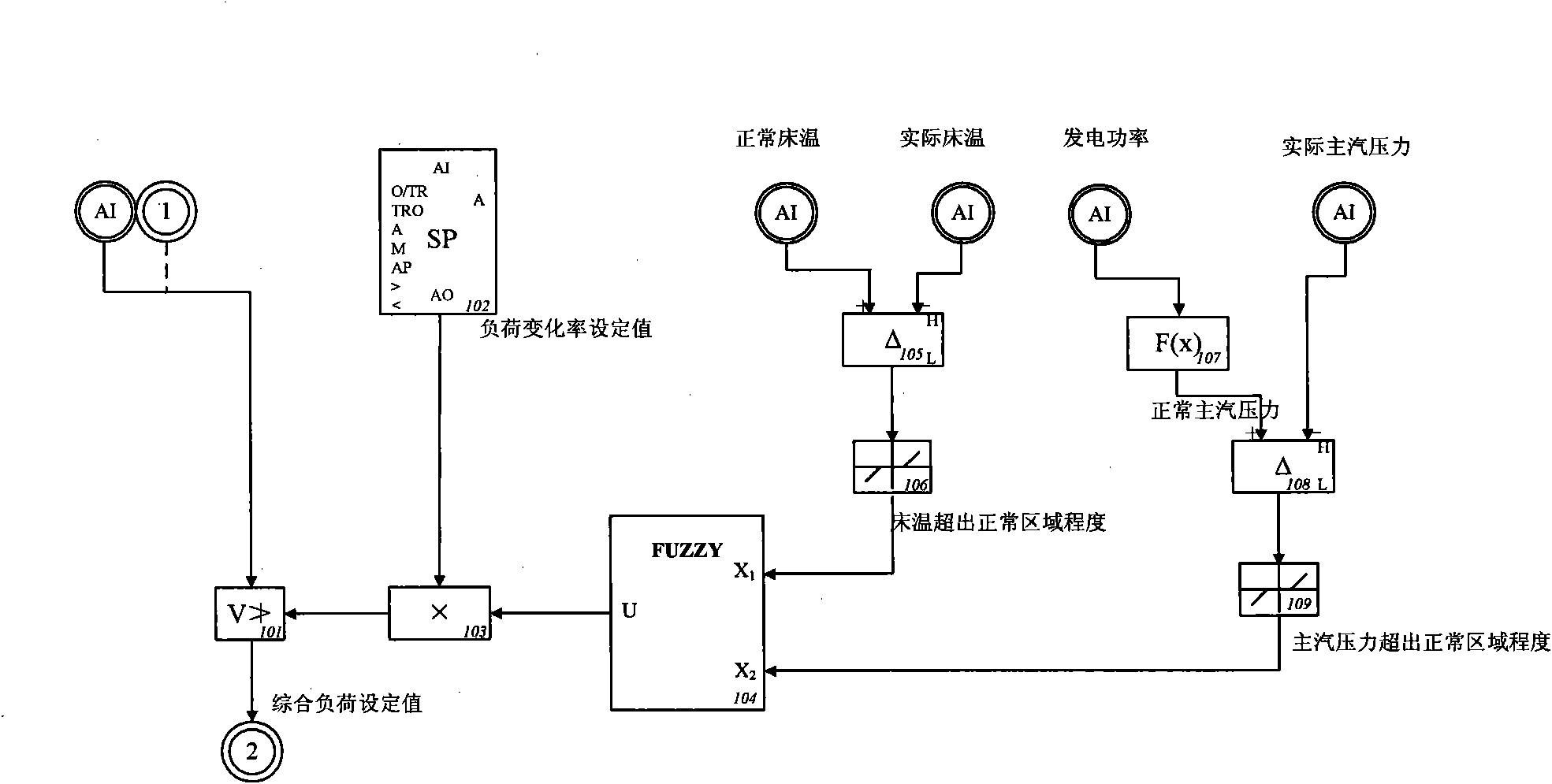

[0038] For the load control center circuit of the present invention, see figure 2 . Its main functions in the coordination device of the new circulating fluidized bed unit are similar to the conventional coordination control: form the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com