Supercooled liquid ice slurry continuous preparation device

A liquid ice and supercooling technology, applied in refrigeration and liquefaction, ice making, refrigerators, etc., to achieve good fluidity, reduce energy consumption, and promote commercial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

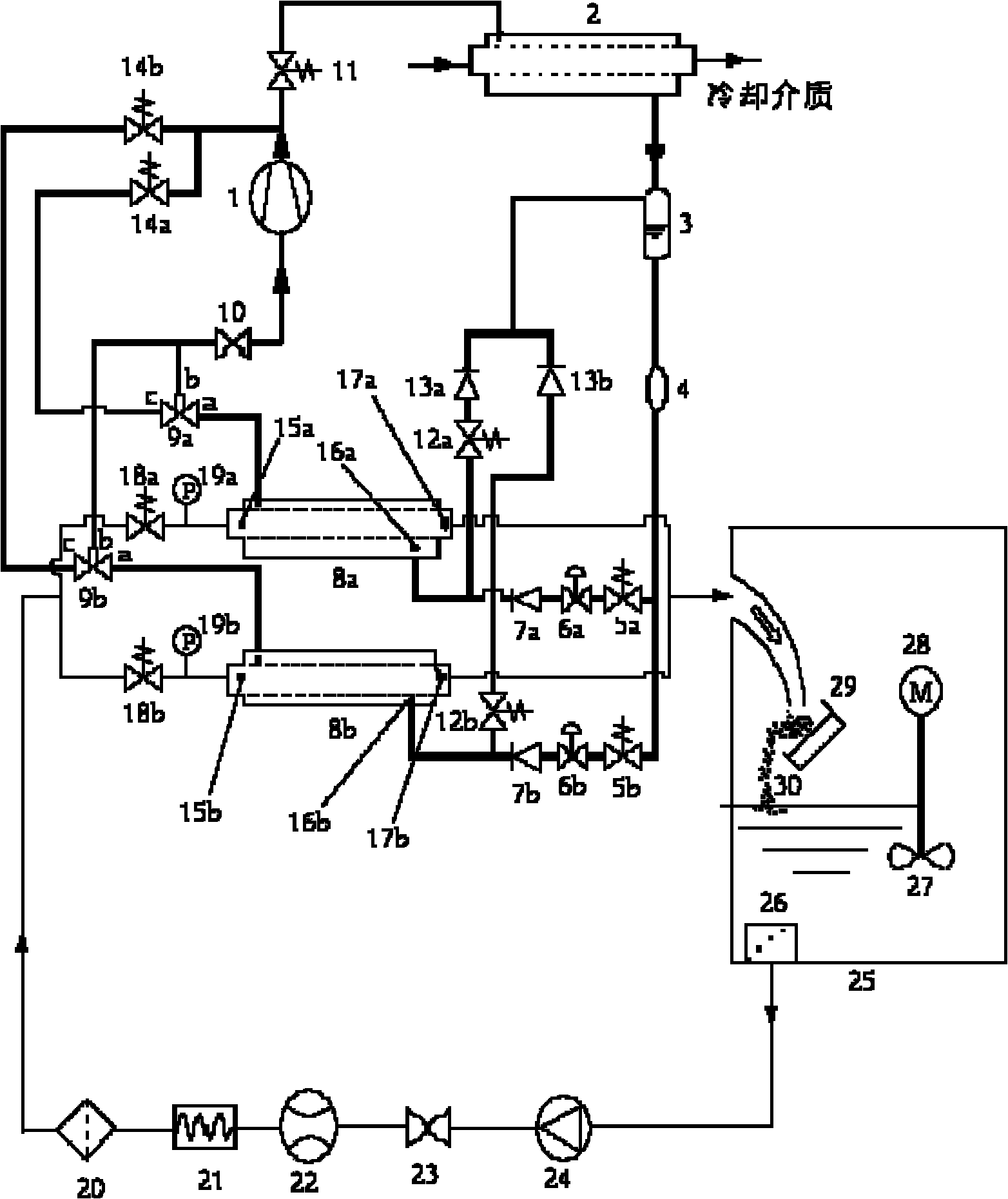

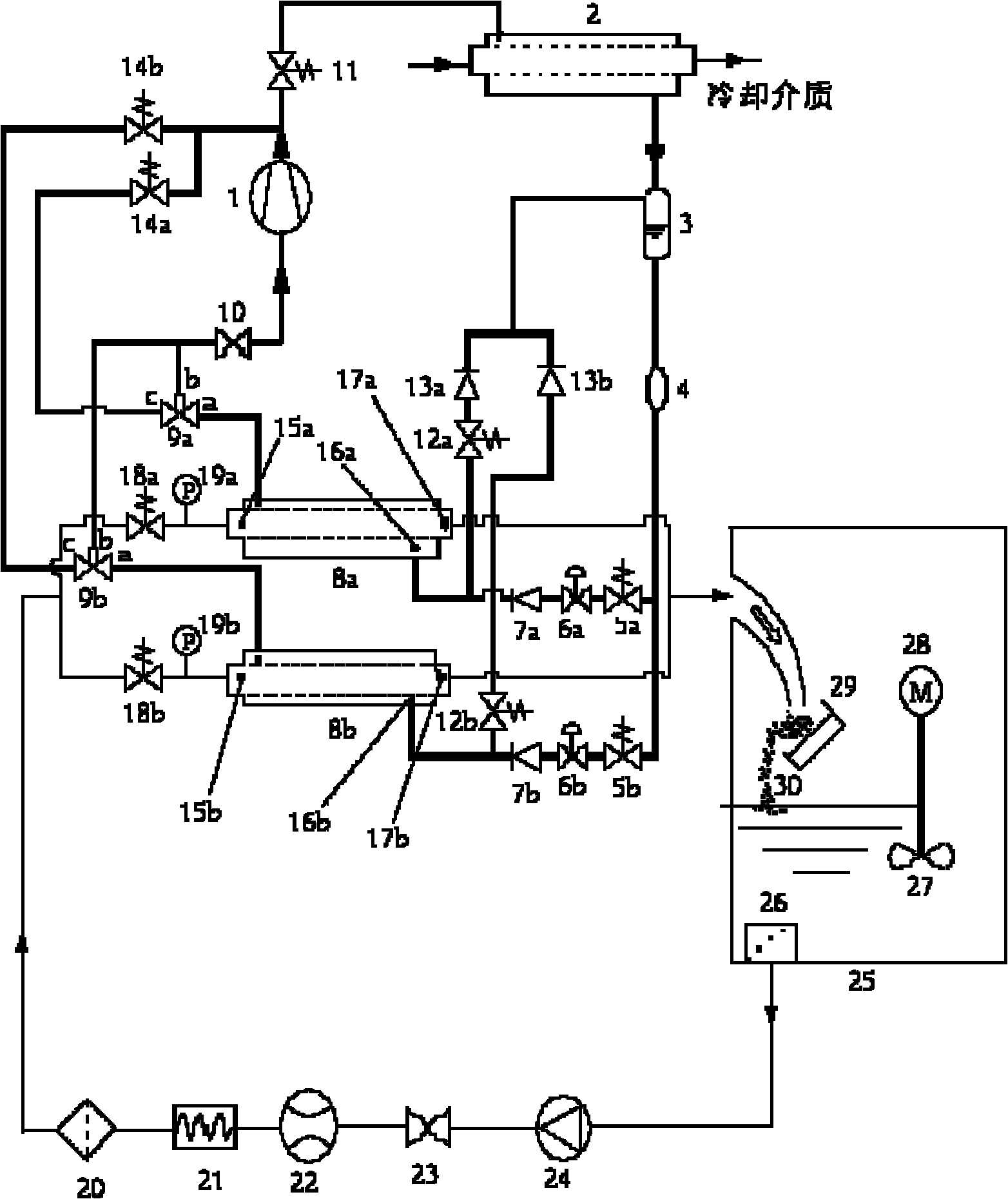

[0015] The device for continuously producing supercooled liquid ice slurry provided by the invention includes a refrigeration system and a supercooled liquid circulation system.

[0016] The present invention will be described in further detail by taking two supercoolers as examples below.

[0017] Such as figure 1 As shown, the subcooled liquid circulation system includes a subcooler assembly, a subcooled liquid circulation processing assembly and an ice storage tank.

[0018] The structure of the subcooler assembly is as follows: the subcoolers 8a and 8b are connected in parallel, and each subcooler can work simultaneously or switchable. Temperature sensors 15a, 17a, 16a are respectively provided at the inlet and outlet of the supercooled liquid and the inlet of the refrigerant of the subcooler 8a, and temperature sensors 15a, 17a, 16a are respectively arranged at the inlet and outlet of the supercooled liquid of the supercooler 8b and the inlet of the refrigerant The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com