System and method for inspecting a wafer

A wafer and defect detection technology, used in measurement devices, semiconductor/solid-state device testing/measurement, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

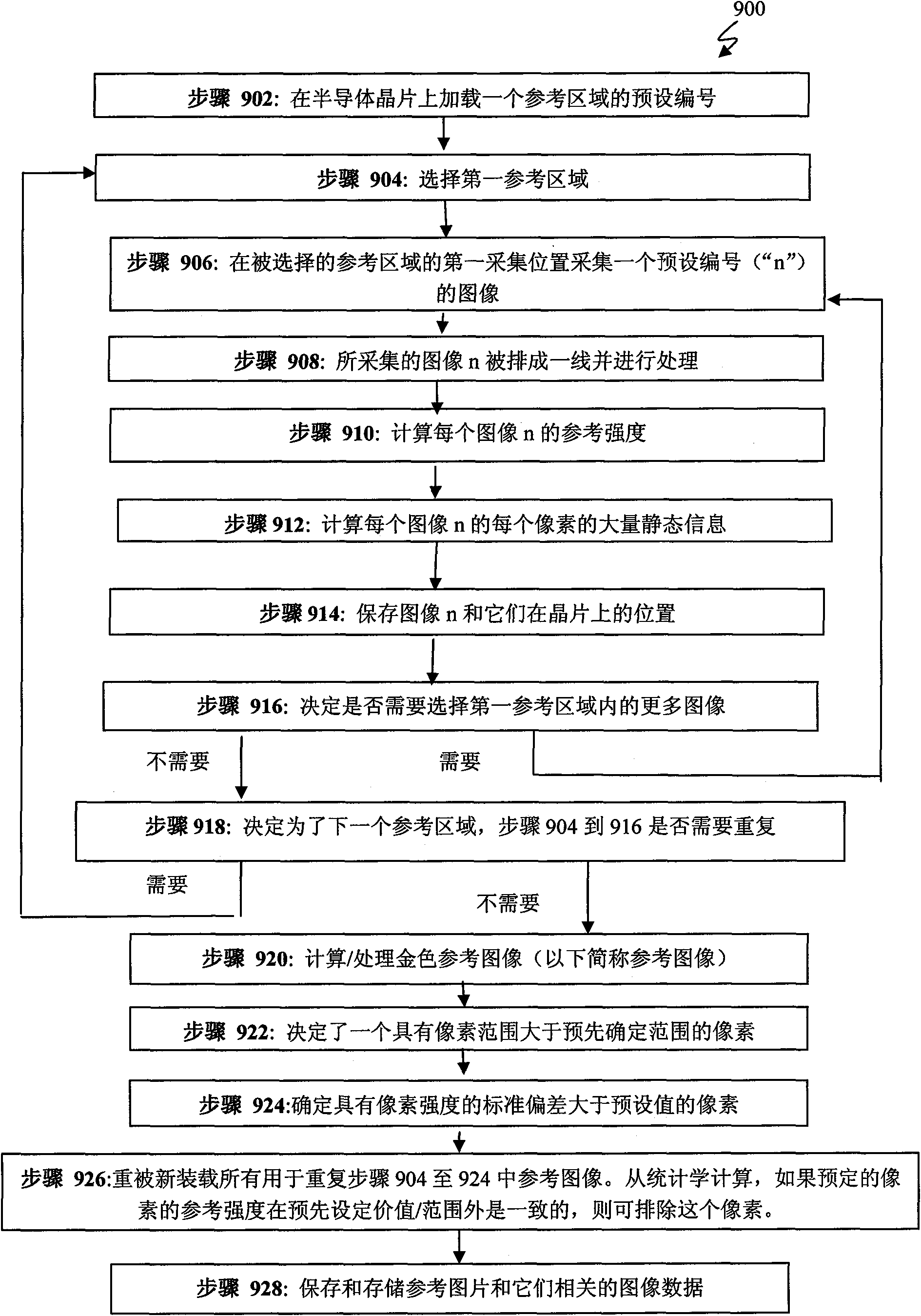

Method used

Image

Examples

Embodiment Construction

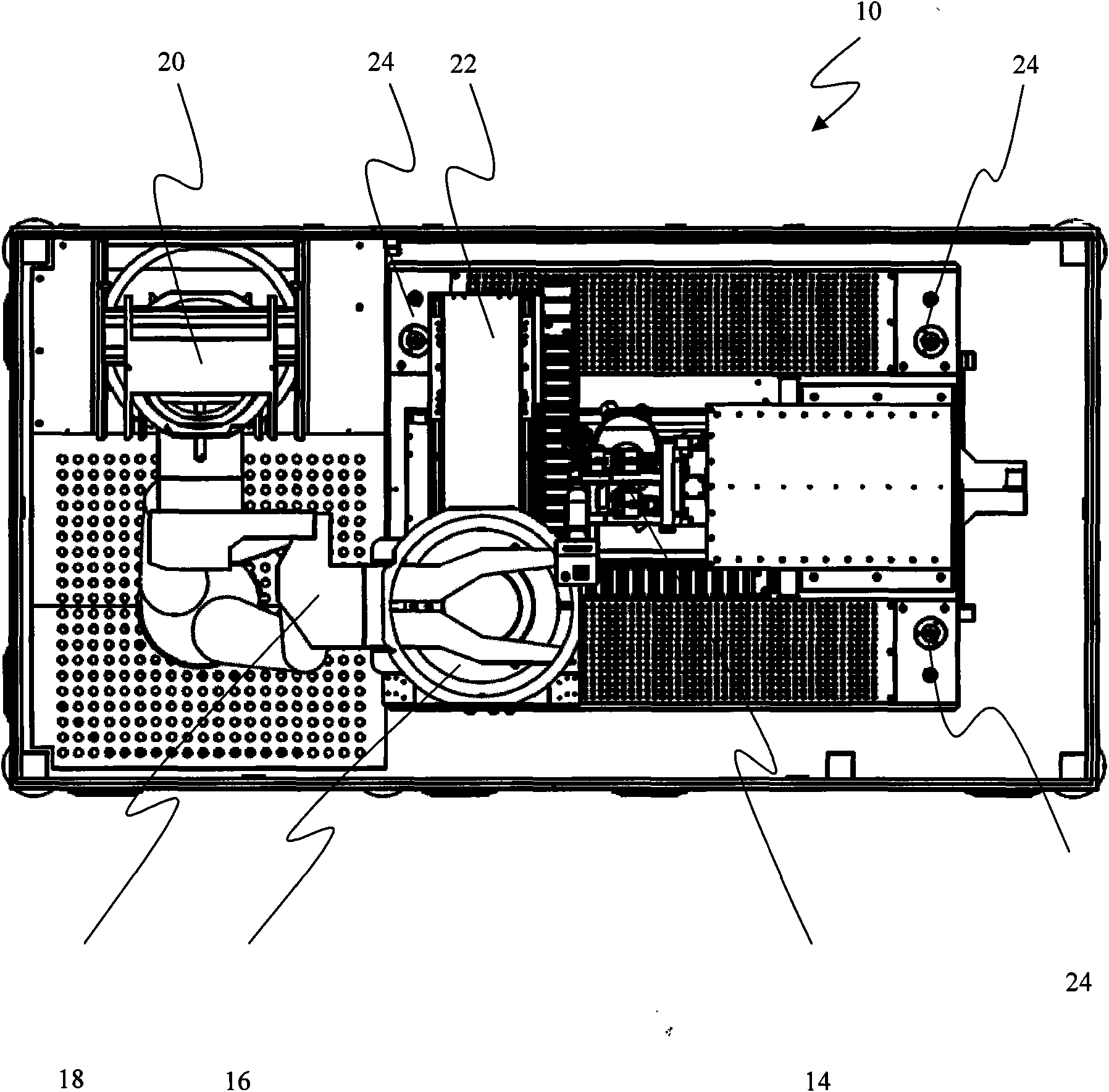

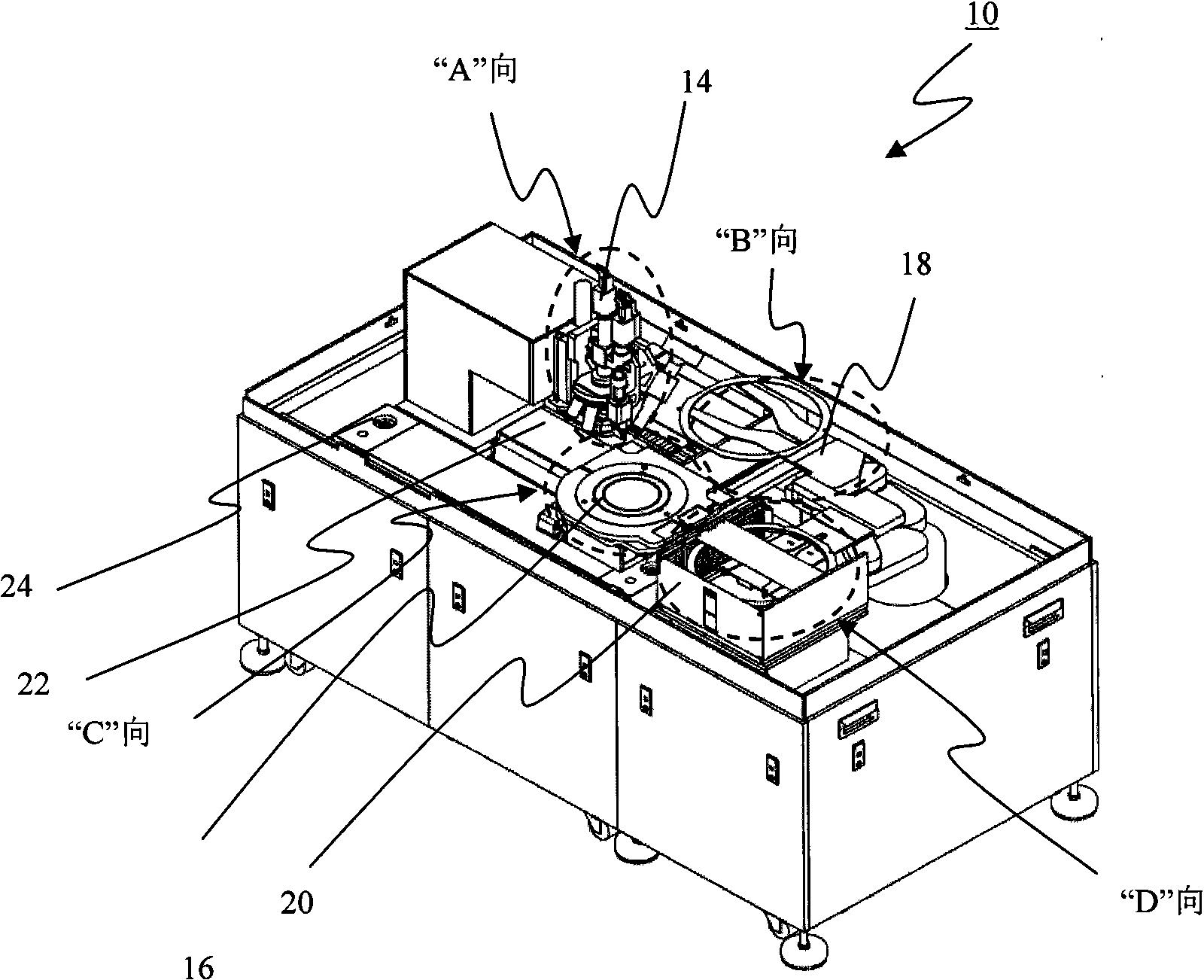

[0063] The inspection of semiconductor components, eg semiconductor wafers and chips, is an increasingly important step in the processing and manufacturing of semiconductors. Due to the increasing complexity of circuits on semiconductor wafers and the improvement of quality standards for semiconductor wafers, there is an increasing need for improved inspection systems and inspection methods for semiconductor wafers.

[0064] Although current semiconductor wafer inspection systems and inspection methods can provide configuration and design flexibility, they cannot simultaneously generate bright-field and dark-field images for dynamic inspection of semiconductor wafers. In addition, flexibility in the semiconductor wafer inspection system is required And the components of the relevant structure of the adjustable space, such as illuminator, camera or image acquisition device, objective lens, filter and its mirror. Due to the increasing complexity of semiconductor wafer electronic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com