Granular green tea with verbena, lemon grass and sweet orange and preparation method thereof

Verbena, granular technology, applied in the field of preparation of granular verbena lemongrass sweet orange green tea, to achieve the effect of increasing nutrition and utilization value, improving utilization efficiency, and increasing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

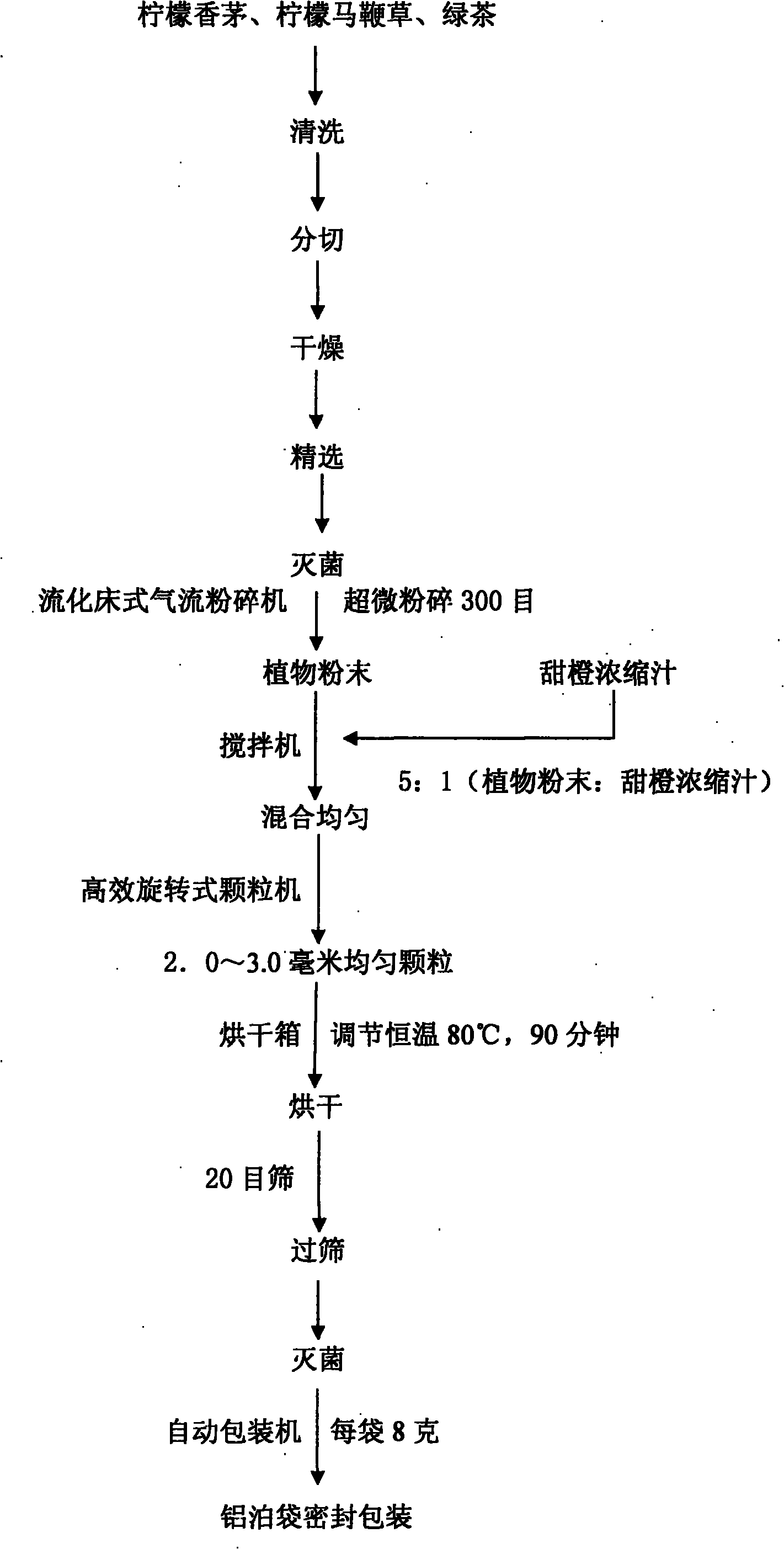

Image

Examples

Embodiment 1

[0025] a. Lemongrass, lemon verbena, and green tea are cleaned, cut, dried, selected, and sterilized respectively;

[0026] b. put the sterilized lemongrass, lemon verbena, and green tea into a superfine pulverizer, and pulverize them into plant powder with a particle size of 300 mesh;

[0027] c. put the pulverized lemongrass, lemon verbena, green tea and sweet orange concentrated juice together into a blender in a ratio of 2.8:1:3.6:1.5 and mix evenly;

[0028] d. Take the stirring mixture in c above and put it into a high-efficiency rotary granulator to make uniform granules of 2.0-3.0 mm;

[0029] e. Put the uniform particles in the above d into a drying box, adjust the constant temperature to 80°C, and dry for 90 minutes;

[0030] f. Pass the dried particles through a 20-mesh sieve, remove the fine powder below 20 mesh, and take the particles on the sieve;

[0031] g. Sterilizing the particles in f above;

[0032] h. Put the sterilized granules into an automatic packag...

Embodiment 2

[0035] a. Lemongrass, lemon verbena, and green tea are cleaned, cut, dried, selected, and sterilized respectively;

[0036] b. put the sterilized lemongrass, lemon verbena, and green tea into a superfine pulverizer, and pulverize them into plant powder with a particle size of 300 mesh;

[0037] c. Put the pulverized lemongrass, lemon verbena, green tea and sweet orange concentrated juice together in a blender in a ratio of 2.4:1:3.4:1.4 and mix evenly;

[0038] d. Take the stirring mixture in c above and put it into a high-efficiency rotary granulator to make uniform granules of 2.0-3.0 mm;

[0039] e. Put the uniform particles in the above d into a drying box, adjust the constant temperature to 80°C, and dry for 90 minutes;

[0040] f. Pass the dried particles through a 20-mesh sieve, remove the fine powder below 20 mesh, and take the particles on the sieve;

[0041] g. Sterilizing the particles in f above;

[0042] h. Put the sterilized granules into an automatic packagin...

Embodiment 3

[0045] a. Lemongrass, lemon verbena, and green tea are cleaned, cut, dried, selected, and sterilized respectively;

[0046] b. put the sterilized lemongrass, lemon verbena, and green tea into a superfine pulverizer, and pulverize them into plant powder with a particle size of 300 mesh;

[0047] c. put the pulverized lemongrass, lemon verbena, green tea and sweet orange concentrated juice into a blender in a ratio of 3.3:1:3.8:1.6 and mix evenly;

[0048] d. Take the stirring mixture in c above and put it into a high-efficiency rotary granulator to make uniform granules of 2.0-3.0 mm;

[0049] e. Put the uniform particles in the above d into a drying box, adjust the constant temperature to 80°C, and dry for 90 minutes;

[0050] f. Pass the dried particles through a 20-mesh sieve, remove the fine powder below 20 mesh, and take the particles on the sieve;

[0051] g. Sterilizing the particles in f above;

[0052] h. Put the sterilized granules into an automatic packaging machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com