High-flux filter material, preparation method thereof and self-inhalation medical mask made of high-flux filter material

A manufacturing method and high-throughput technology, applied in chemical instruments and methods, applications, clothing, etc., can solve problems such as large air resistance and inability to achieve spontaneous breathing, and achieve small air resistance, good ventilation performance, and good ventilation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

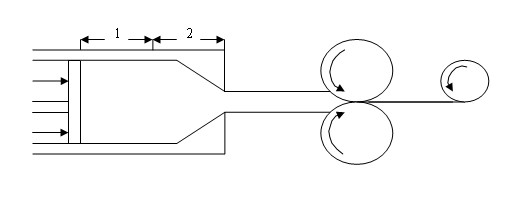

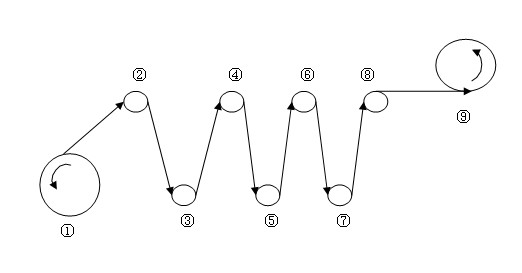

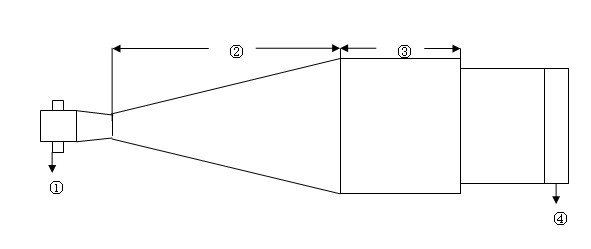

[0033] Such as figure 1 , figure 2 , image 3 As shown, the manufacturing method of the high-throughput filter material is: firstly, the polytetrafluoroethylene microporous membrane is made. To improve the flux of PTFE microporous membrane, the thickness of PTFE microporous membrane must be reduced. At present, the thickness of PTFE microporous membrane is 5-10 μm. Because it is too thick, the flux cannot be improved. To reduce the thickness, the stretching ratio must be increased, and the stretching ratio is limited by the ductility of the PTFE baseband. Due to the various models, molecular weight ranges, specific gravity, bulk density, and average particle size of PTFE resins, the elongation at break is also different.

[0034] The tensile ratio test of three specifications is as follows:

[0035] PTFE resin model

601A (DuPont, USA)

F106 (Daikin, Japan)

F104 (Daikin, Japan)

molecular weight

15 million-20 million

600,000-5 million

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com