Elevation angle automatic regulation variable spray nozzle

An automatic adjustment and elevation angle adjustment technology, applied in the direction of the injection device, etc., to achieve the effect of simple overall structure, stable performance, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

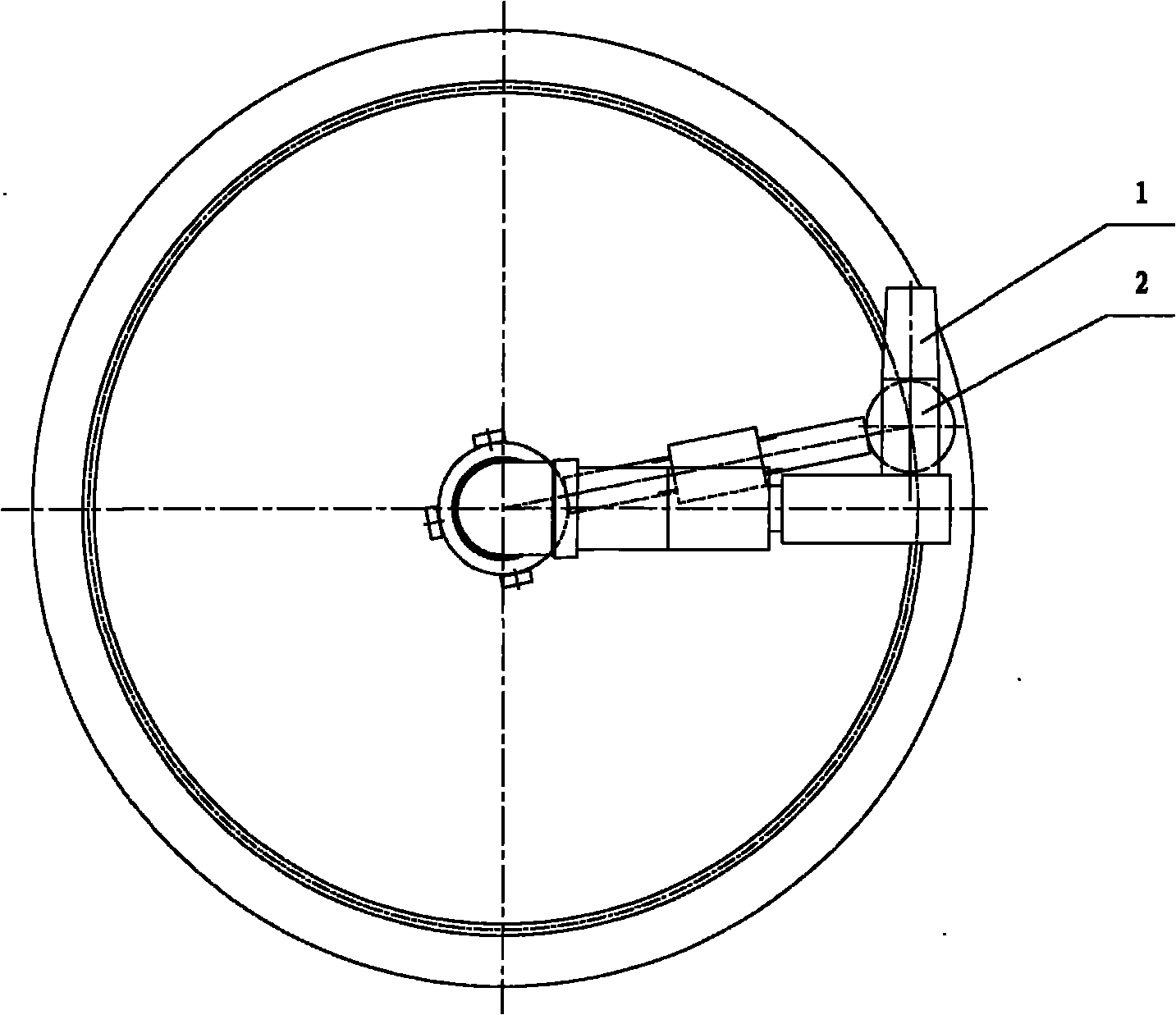

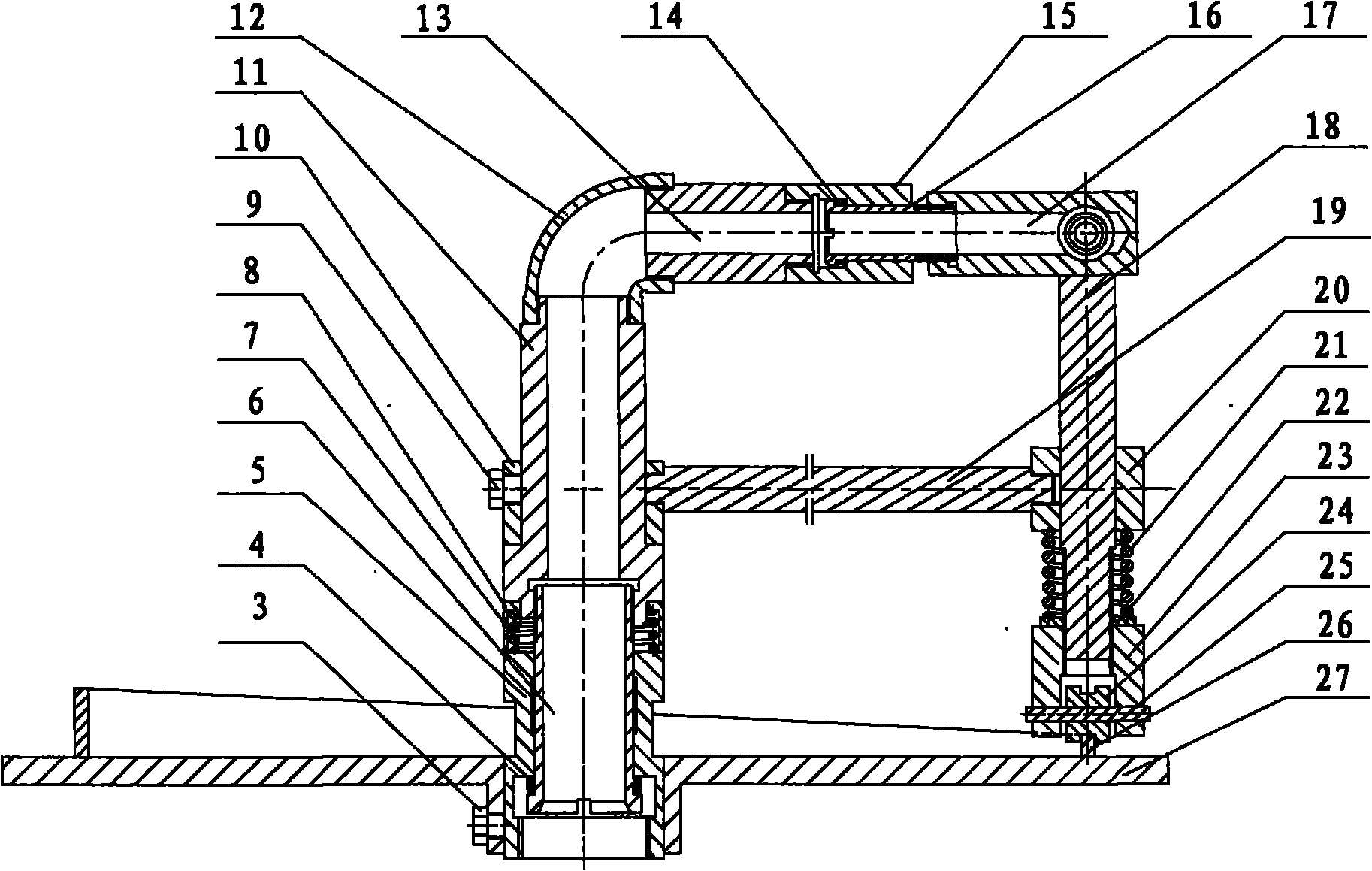

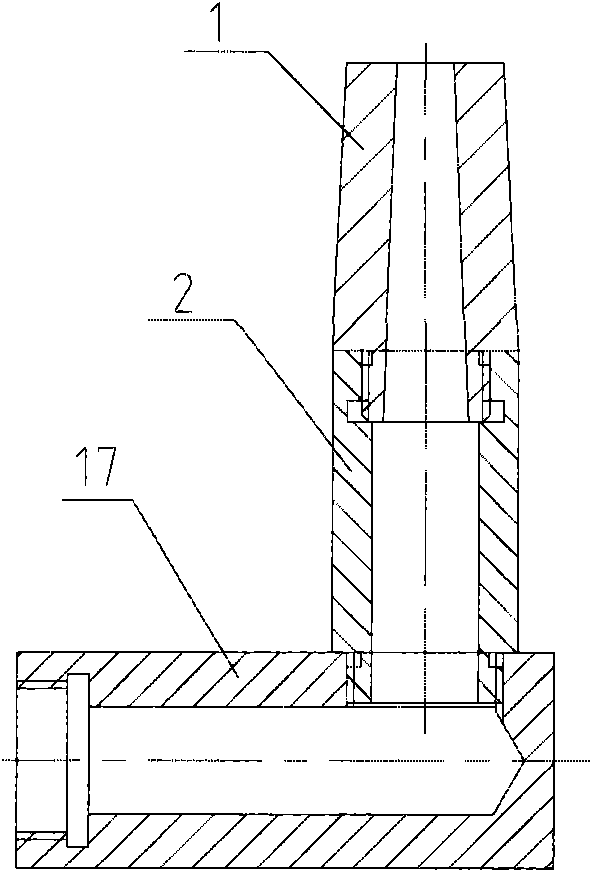

[0013] The elevation angle automatic adjustment variable sprinkler nozzle is composed of four parts: the nozzle assembly, the rotating connector, the elevation angle adjustment mechanism, and the flow channel mechanism. The key parts of the present invention are the spray head assembly, the rotary connection piece and the elevation angle adjustment mechanism. The present invention realizes variable spraying by changing the elevation angle of the spray head and further changing the range of the spray head.

[0014] The working process is as follows: the elevation angle is automatically adjusted and the variable sprinkler head is powered by the reaction force of the water flow. The rotating shaft 16 and the shaft sleeve 15 form a rotating pair, so that the spray body 2 and the nozzle 1 can rotate on a vertical plane with the adapter 17 and the rotating shaft 16 as axes. The guide rail 26 is welded on the chassis 26, and is fixed on the swivel connection seat 5 by the bolt 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com