Method for performing automatic surfacing repair on damaged metal part

A metal parts, automatic surfacing welding technology, applied in metal processing equipment, welding equipment, welding accessories, etc., can solve the problems of uneven quality of manual repair, difficulty in batching, high surfacing layer, etc. The effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

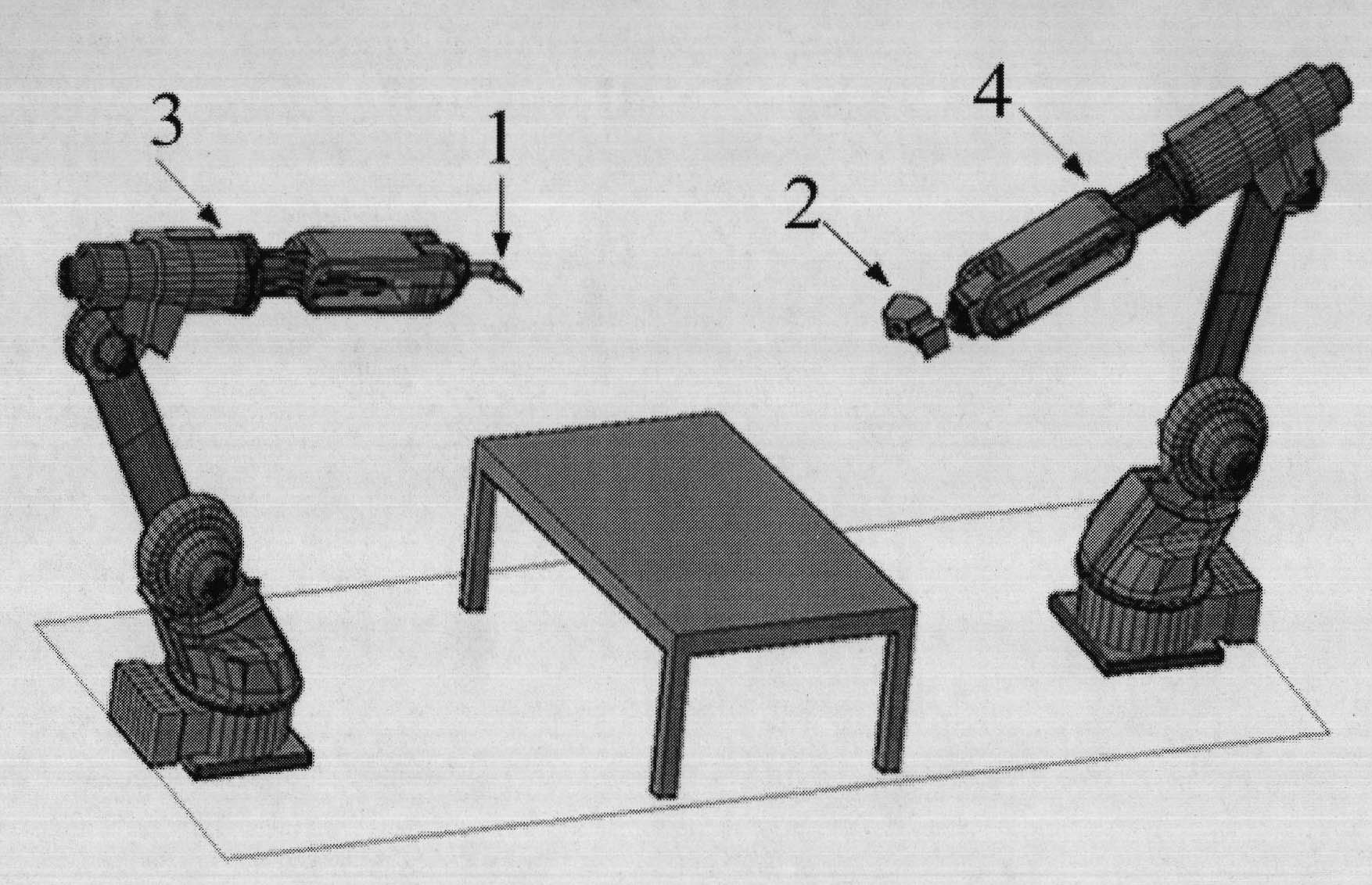

[0014] The system consists of two parts, measuring robot and arc welding robot. Among them, the measurement robot is composed of a line structured light sensor 2 and a 1# six-degree-of-freedom robot arm 4, and the robot arm uses the HP6 robot of motoman company. The arc welding robot consists of a welding torch (1) and a 2# six-degree-of-freedom mechanical arm (3). The integrated product selects MOTOMAN-SSA2000 arc welding robot from motoman company.

[0015] work process:

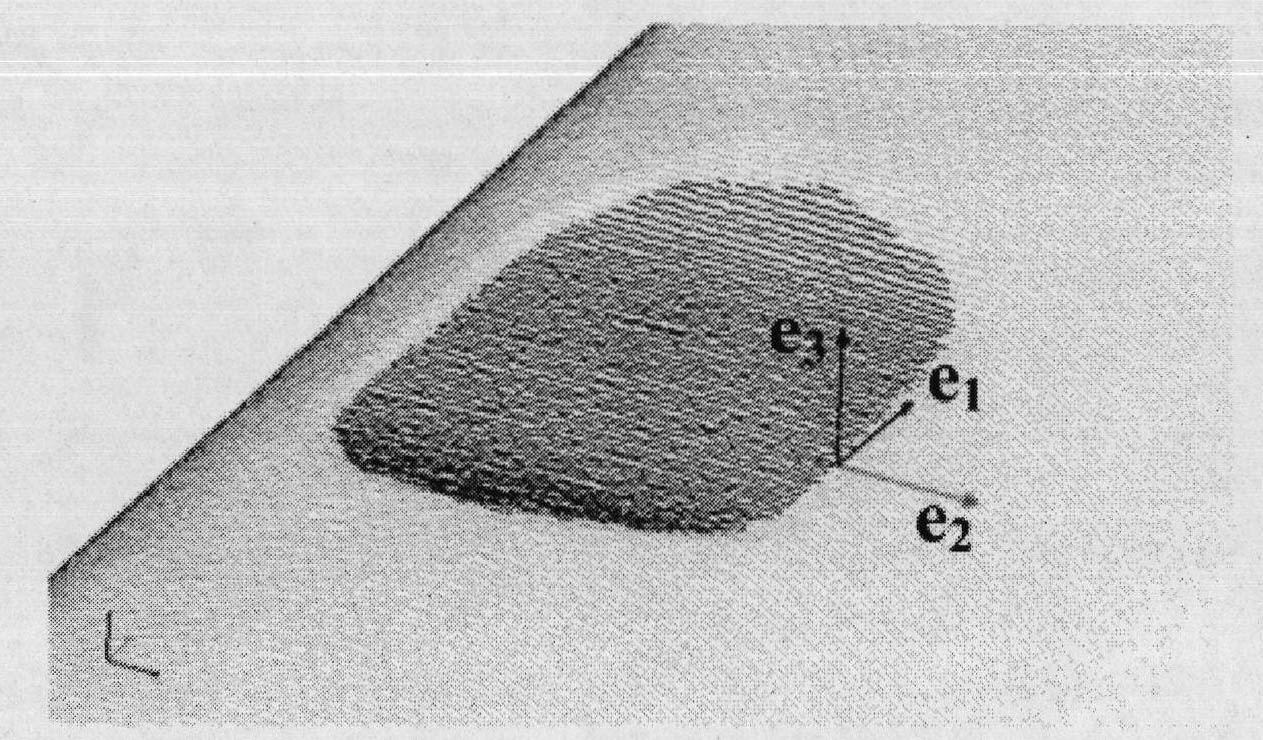

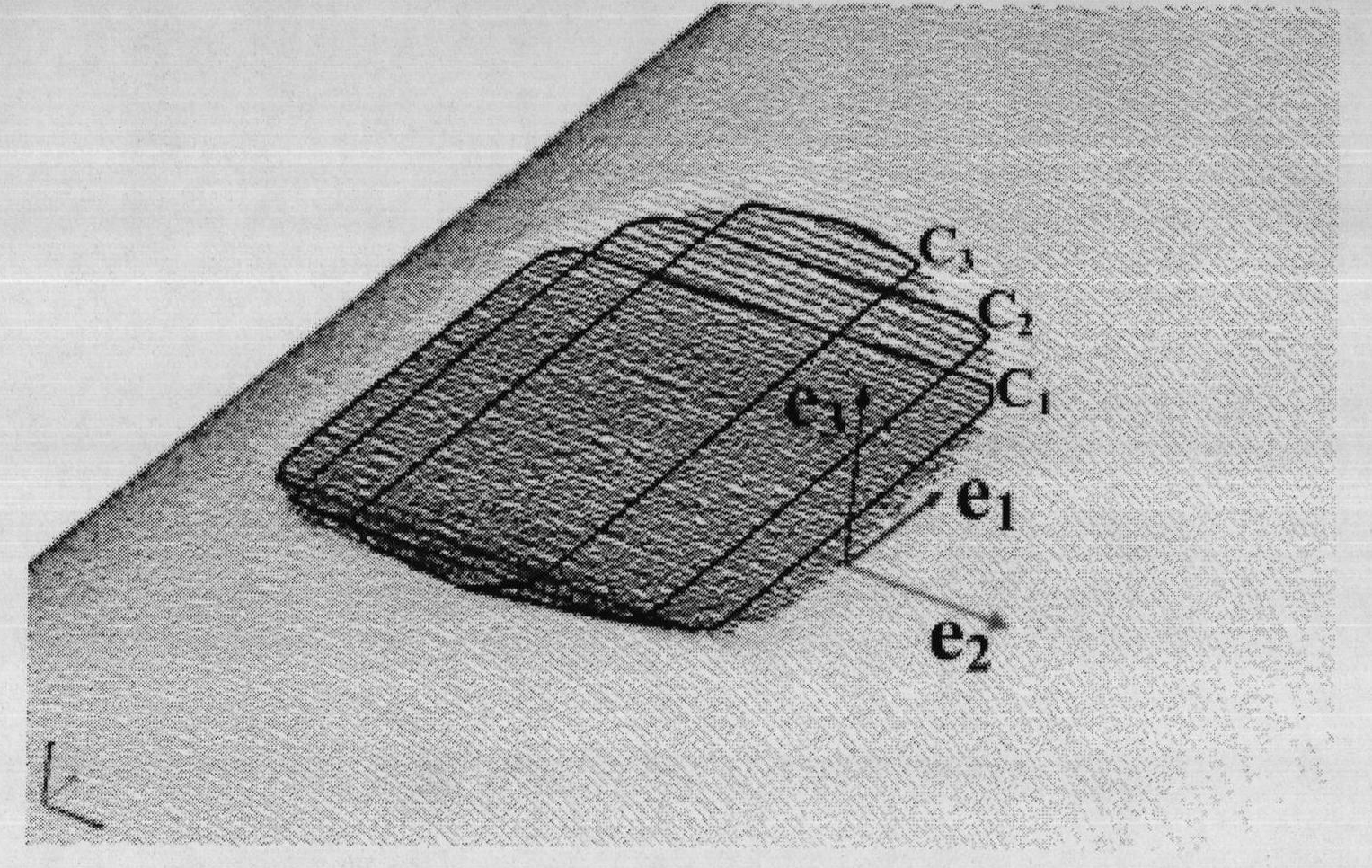

[0016] The working process of the system includes three parts: scanning and positioning of damaged parts, extraction of damaged areas, and automatic generation of repair paths.

[0017] (1) Surface scanning and positioning of damaged parts:

[0018] The data of the metal part profile obtained by the application of the measuring robot is the 3D point cloud data in the base coordinate system of the measuring robot. The relationship between the base coordinate system of the measuring robot and the base coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com