Industrial vacuum tank vehicle

A technology of vacuum tanks and automobiles, which is applied in the direction of motor vehicles, goods transport vehicles, and vehicles used for freight transportation. It can solve the problems of heavy vehicle weight, reduced transportation capacity of a single vehicle unit, and heavy load of the filtration system, so as to simplify the overall layout. Avoid high temperature burning and enhance the effect of filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

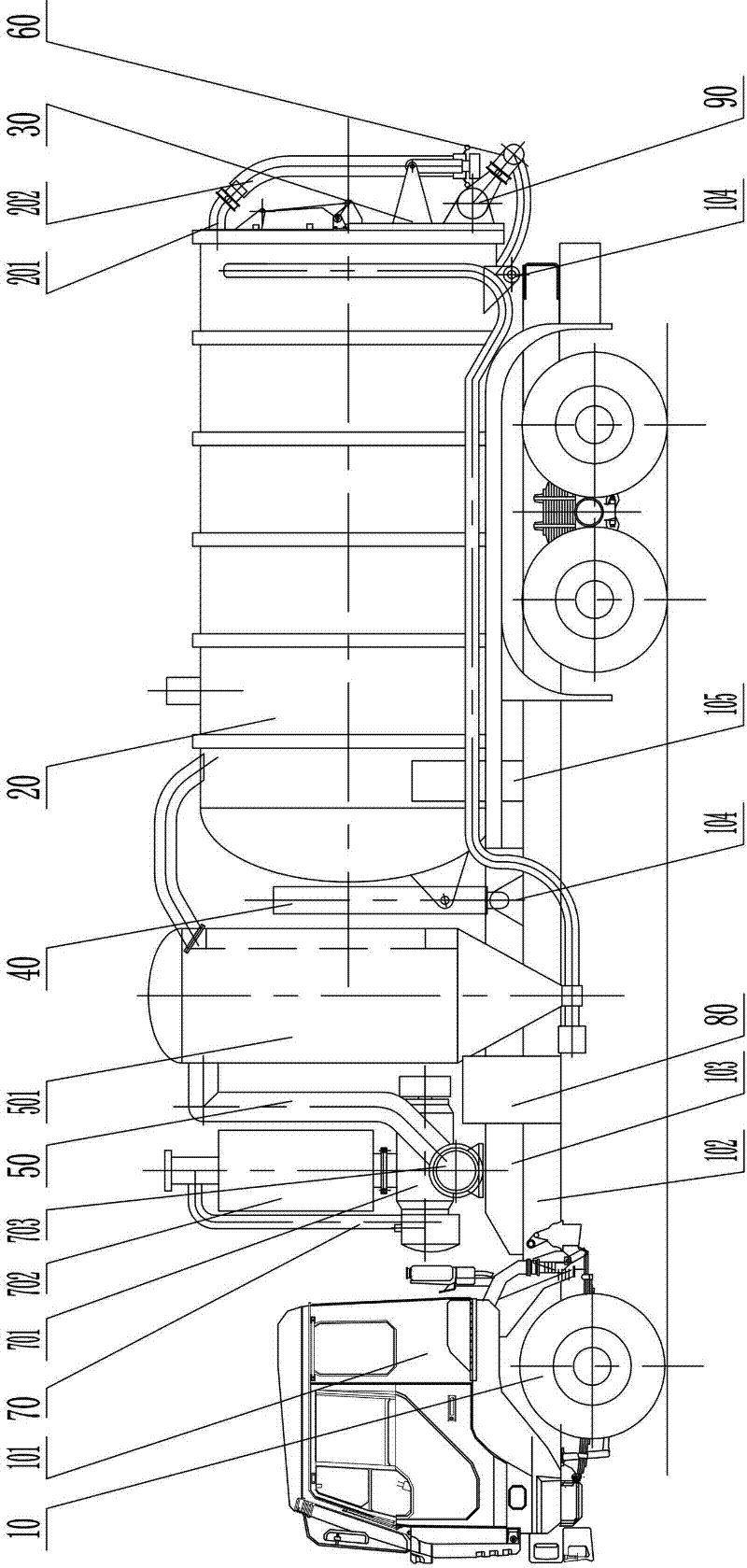

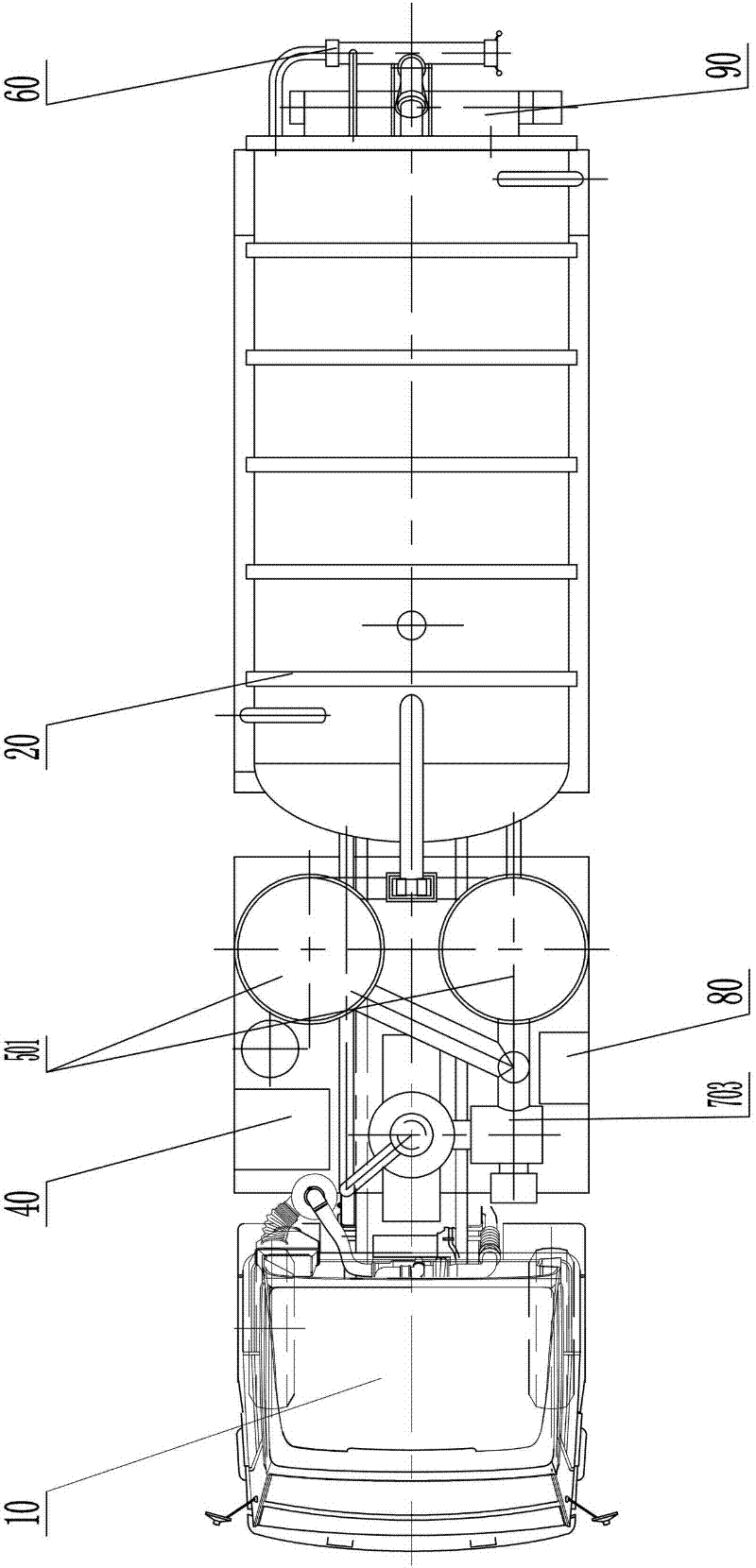

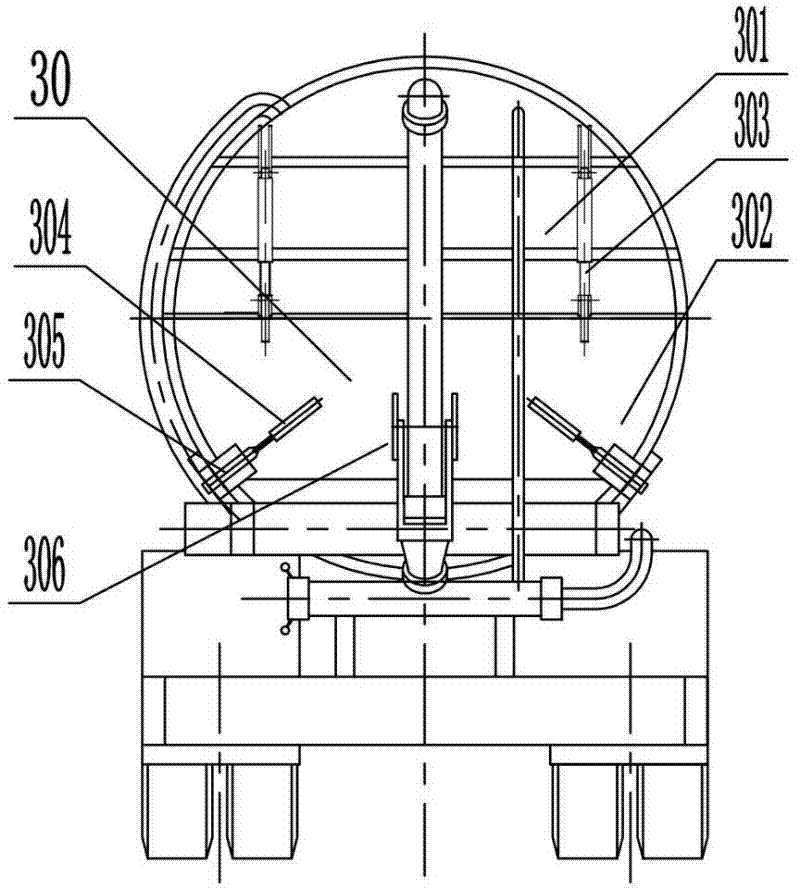

[0027] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the industrial vacuum tank vehicle of the present invention includes a chassis 10 and a storage tank 20 installed on the chassis 10, a tailgate assembly 30, a hydraulic dumping assembly 40, a double-circuit cyclone bag combination filter 50, and a pneumatic discharge Device 60, two-way vacuum system 70, control system 80 and screw unloader 90, the rear end of the storage tank 20 away from the cab 101 is hinged on the chassis 10, the front bottom of the storage tank 20 close to the cab 101 is connected to the hydraulic pressure The dump assembly 40 is hinged; the tailgate assembly 30 is installed at the tail end of the material storage tank 20, and the top of the material storage tank 20 tail end is provided with a suction pipe 202, and a 45-degree angle is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com