Method for reclaiming phosphorous compound

A phosphorus compound and phosphorus-enriched technology, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems that have not been reported, and achieve the effects of broad market prospects, obvious economic benefits, and high agricultural use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The dewatering filtrate of urban sewage plant sludge is rich in phosphorus, which is a typical phosphorus-rich sewage. The test took the sludge dewatering filtrate of a sewage plant in Chaohu City as the research object, and its pH value was 7.2, P0 4 3- The concentration is 1.4mmol / L. First, 732-type cation exchange resin was used to remove heavy metals in the filtrate, the liquid-solid ratio was 5mL / g, the reaction time was 30min, and the stirring speed was 250rpm. Then, add 40g / L magnesium chloride and 10g / L ammonium chloride solution (Mg:N:P=1.3:1.3:1) in the filtrate, adopt the pH value of the potassium hydroxide adjustment solution of 4mol / L at 9.5-10.5 In between, the solution was stirred at a speed of 400rpm for 15min, and a precipitate was formed. After filtering with filter paper, the desired struvite precipitate is obtained.

[0029] The results show that the sludge dewatering filtrate is rich in phosphorus. When the liquid-solid ratio of cation exchange ...

Embodiment 2

[0031] Step 1: The poultry manure is taken from a breeding center in Shanghai. The poultry manure is mainly chicken manure with a moisture content of 72%. After incinerating for 3 hours under aerobic conditions at 800°C, the required poultry manure ash sample was obtained. After grinding, the average particle size was 150 μm, and the P content (in P 2 o 5 Total) is 12%; the second step: extract the phosphorus in the excrement ash with the hydrochloric acid stripping method, the extraction liquid-solid ratio is 50ml / g, and the concentration of hydrochloric acid is 0.2mol / L, and the extraction time is 120min, and the horizontal rotating speed is 150rpm; the third Step: Add 40g / L magnesium chloride and 10g / L ammonium chloride solution (Mg:N:P=1.3:1.3:1) to the extract, and use 4mol / L sodium hydroxide to adjust the pH value of the solution at 9.5- Between 10.5 and the solution was stirred at 400rpm for 15 minutes, and a precipitate formed. After filtering with filter paper, the ...

Embodiment 3

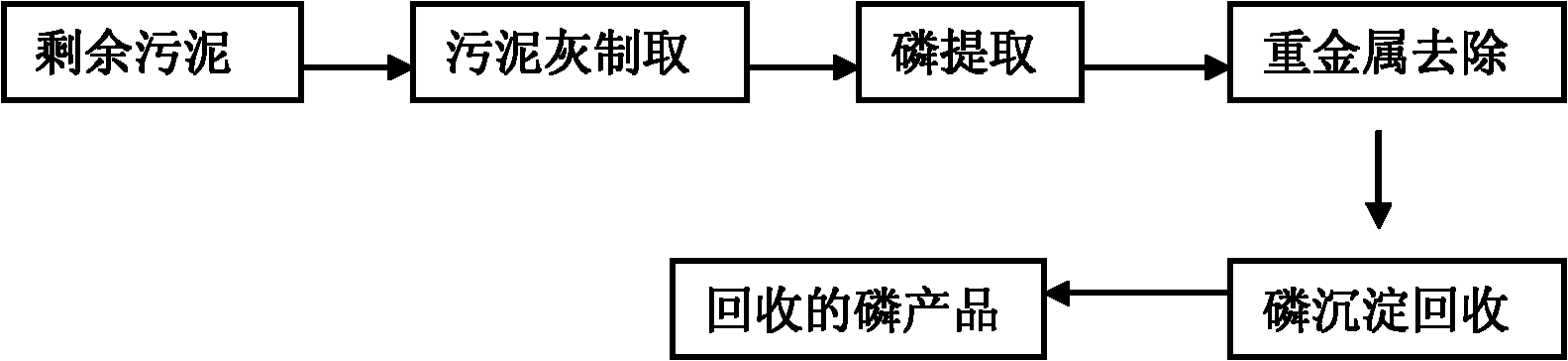

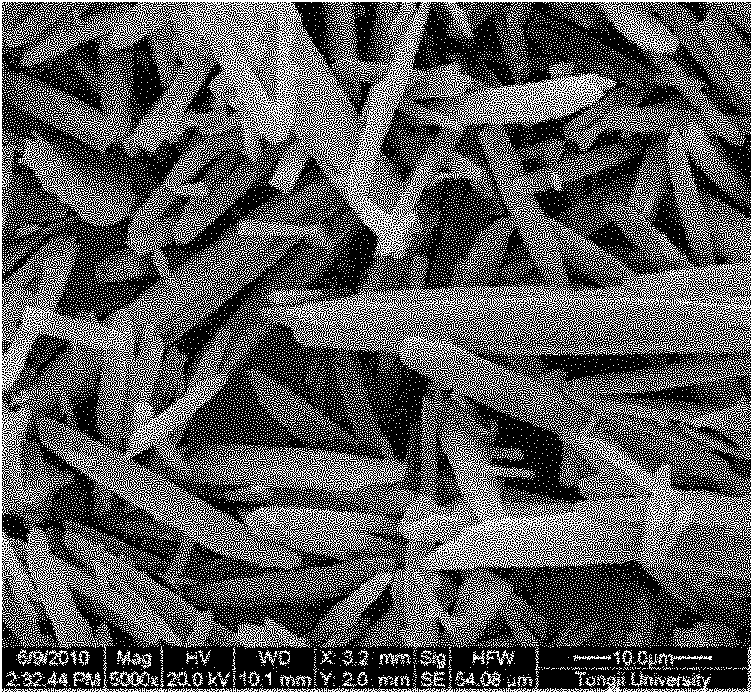

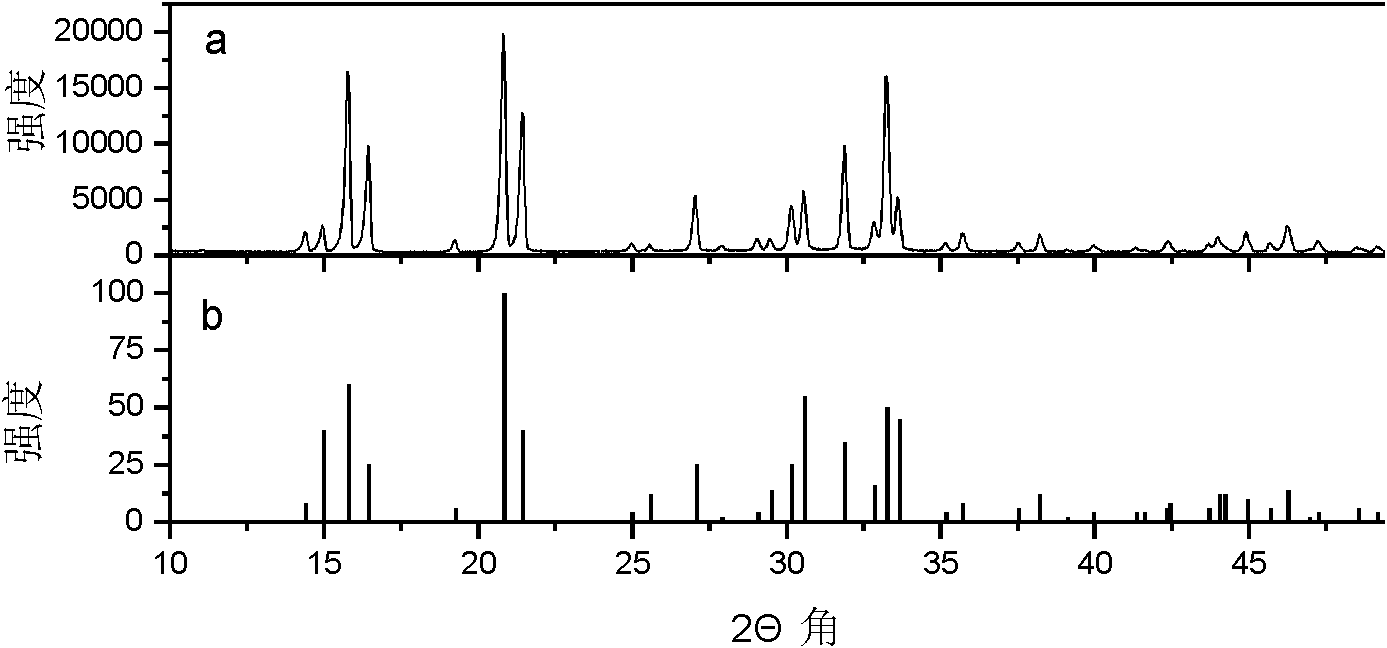

[0034]figure 1 It is a schematic diagram of the technological process of reclaiming phosphorus from sludge ash of urban sewage plant in the present invention. Step 1: The dewatered sludge is taken from an urban sewage plant in Shanghai, with a water content of 83.5%. Obtain the required sludge ash sample after being incinerated under aerobic conditions at 800°C for 3 hours, the average particle size after grinding is 150 μm, and the P content in the sludge ash (in P 2 o 5 Total) is 15%; Second step: extract the phosphorus in sludge ash with hydrochloric acid stripping method, extracting liquid-solid ratio is 50ml / g, and hydrochloric acid concentration is 0.2mol / L, and extraction time is 120min, and horizontal rotating speed is 150rpm; Three steps: use 732 type cation exchange resin to remove heavy metals in the extract, the liquid-solid ratio is 25mL / g, the reaction time is 30min, and the stirring speed is 250rpm; the fourth step: add 40g / L magnesium chloride and 10g / L ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com