Activated carbon-supported nitrile group ionic liquid-palladium catalyst for synthesizing polyketone and preparation method thereof

A technology of ionic liquid and activated carbon, which is applied in the field of catalysts for the synthesis of polyketones, can solve problems such as wear, loss of metal ions, and reduced catalytic activity, and achieve the effects of large contact area, increased reactivity, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

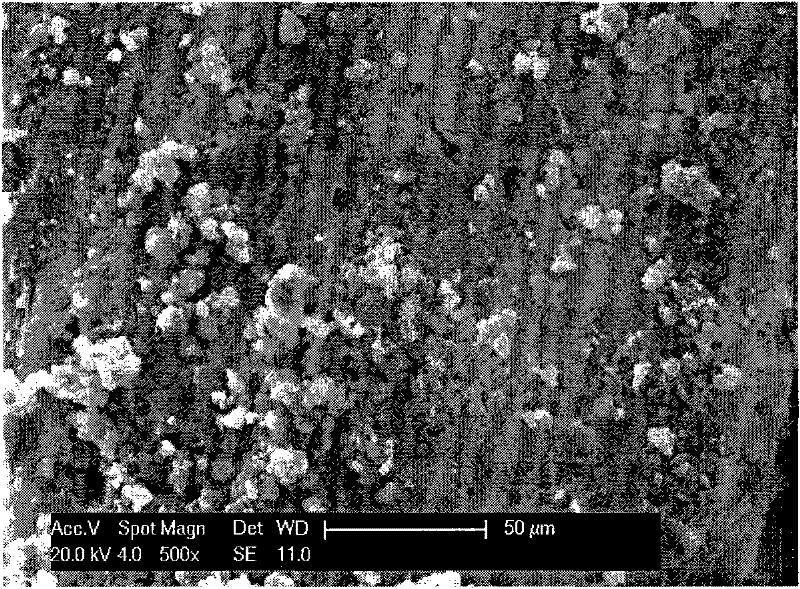

[0014] Weigh 10g of 50-60 mesh activated carbon, add 50mL of hydrochloric acid solution with a mass concentration of 20%, soak for 2h at a temperature of 50°C, add the obtained activated carbon into an ammonia solution with a mass concentration of 2% and heat it to 100°C for 10min, then Add 100mL of deionized water to the activated carbon after suction filtration and heat to 100°C for 10 minutes, then filter with suction and repeat three times to remove Cl - , NH 4 + , then add 100ml of deionized water, 15ml of hydrogen peroxide with a mass concentration of 30% and 5mL of a sodium hypochlorite solution with a mass concentration of 10%, and after treating at room temperature for 4 hours, filter, wash, and vacuum dry at a temperature of 40°C for 12 hours to obtain pretreated activated carbon , sealed and kept for later use.

[0015] Dissolve 0.2g of N-valeronitrile-N'-methylimidazolium hexafluorophosphate ionic liquid and 0.211g of palladium acetate in 15ml of acetone, stir at...

Embodiment 2

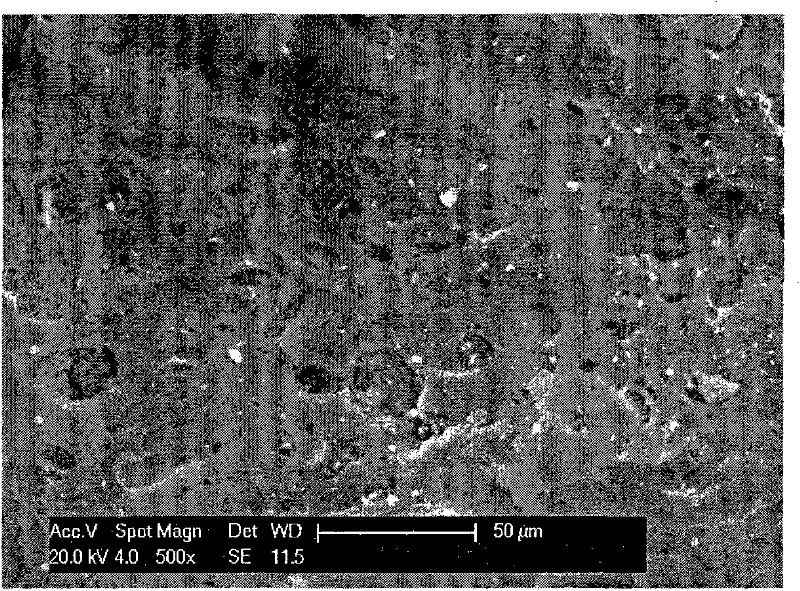

[0017] The steps of this example are the same as those in Example 1, except that the amount of N-valeronitrile-N'-methylimidazolium hexafluorophosphate ionic liquid is 0.15 g, and the amount of palladium acetate is 0.1477 g to obtain activated carbon-supported nitrile Ionic liquid catalyst, the theoretical loading mass of the catalyst is 7%Pd-15%[C 4 CNmim] + PF 6 - -1gC(b). The actual loading of palladium was determined to be 5.23% by using a 180-80 polarized Zeeman atomic absorption spectrometer from Hitachi, Japan.

Embodiment 3

[0019] The steps of this example are the same as in Example 1, except that the amount of N-valeronitrile-N'-methylimidazolium hexafluorophosphate ionic liquid is 0.1 g, and the amount of palladium acetate is 0.1055 g to obtain activated carbon-supported nitrile Ionic liquid catalyst, the theoretical loading mass of the catalyst is 5%Pd-10%[C 4 CNmim] + PF 6 - -1gC(c). The actual loading of palladium was determined to be 3.46% by using a 180-80 polarized Zeeman atomic absorption spectrometer from Hitachi, Japan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com