Method for building impermeable tailings dams with high scattered piles by waste rocks

A tailings dam and rock drainage technology, which is applied in filling, construction, solid waste removal, etc., can solve problems such as raising the elevation of the tailings dam crest, prolonging the service life, and insufficient volume of the dump site, so as to reduce land occupation , extend the service life, reduce the effect of land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in detail below in conjunction with the examples.

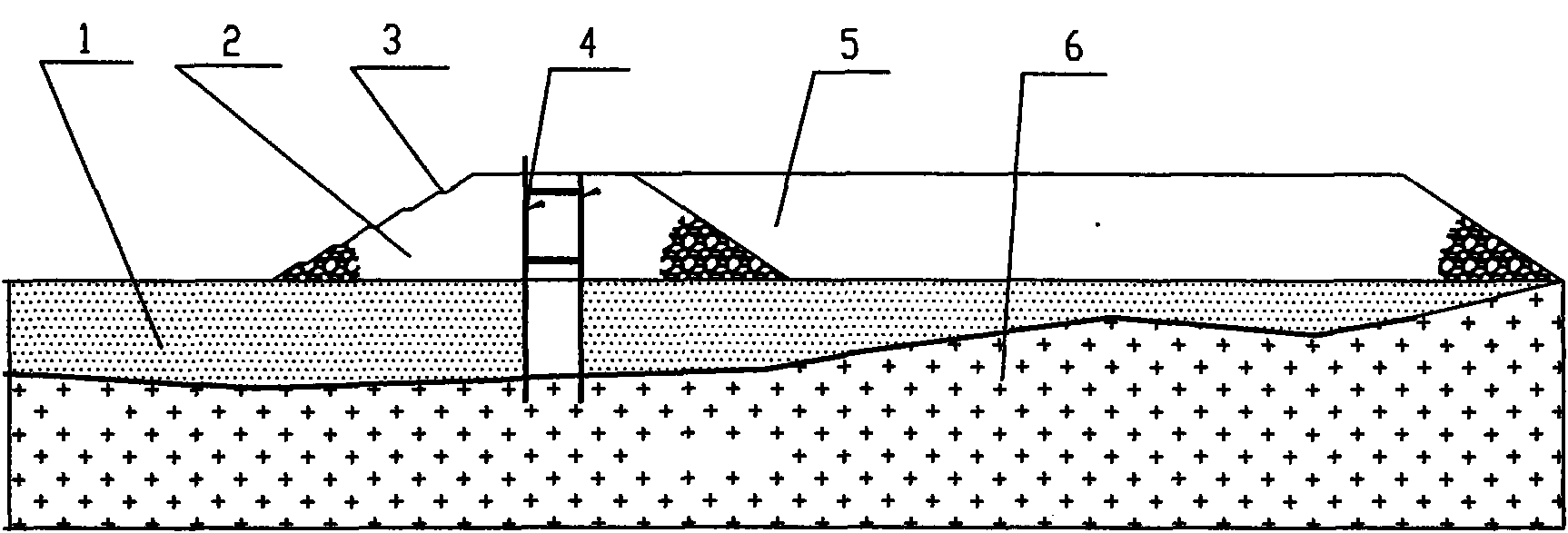

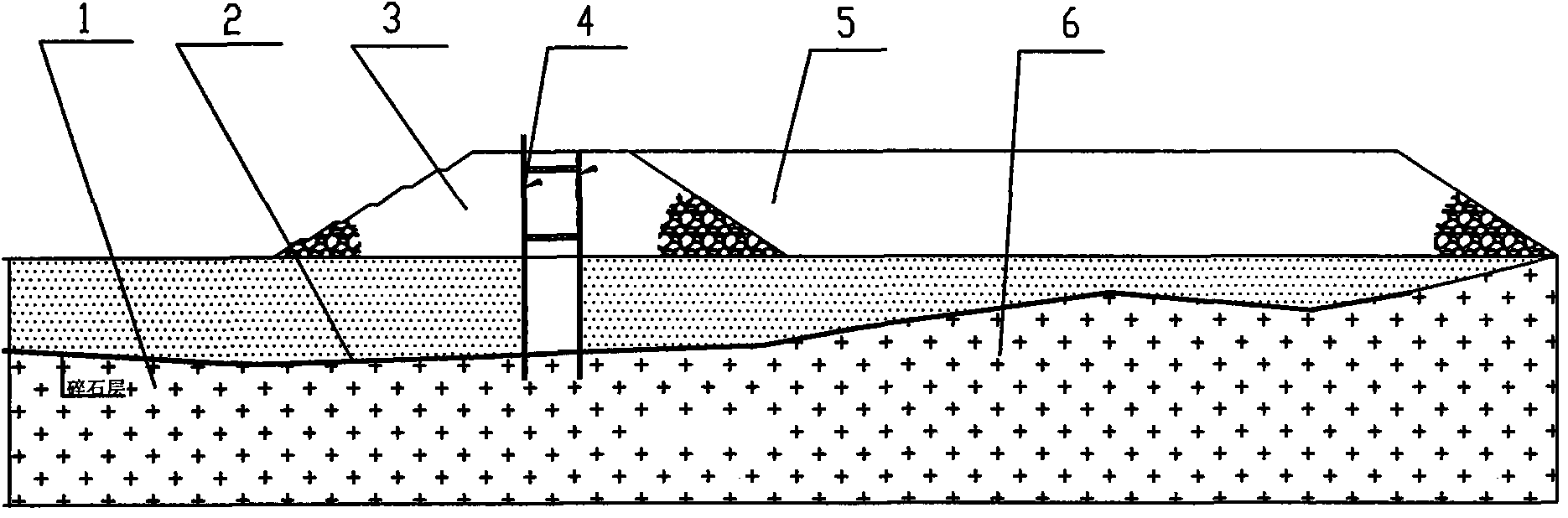

[0023] Such as figure 1 Shown, the method for building high bulk impermeable tailings dams by row rock of the present invention is characterized in that comprising the following steps:

[0024] 1) Analysis of tailings sand carrying capacity

[0025] According to the physical and mechanical properties of the tape-discharged rocks and the physical and mechanical indicators obtained from the tailings sand test, the bearing capacity of the tailings sand is calculated through the formula of L.Prandtl,

[0026] 2) Design double-layer reinforced concrete anti-seepage wall 4

[0027] The cut-off wall 4 is a double-layer reinforced concrete frame structure, and a transverse wall is arranged between the double-layer cut-off walls.

[0028] 3) Make the double-layer reinforced concrete anti-seepage wall foundation,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com