Environment-friendly and energy-saving constant pressure hot water boiler

A hot water boiler, environmental protection and energy-saving technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low thermal efficiency, insufficient boiler combustion, environmental pollution, etc. Reasonable, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

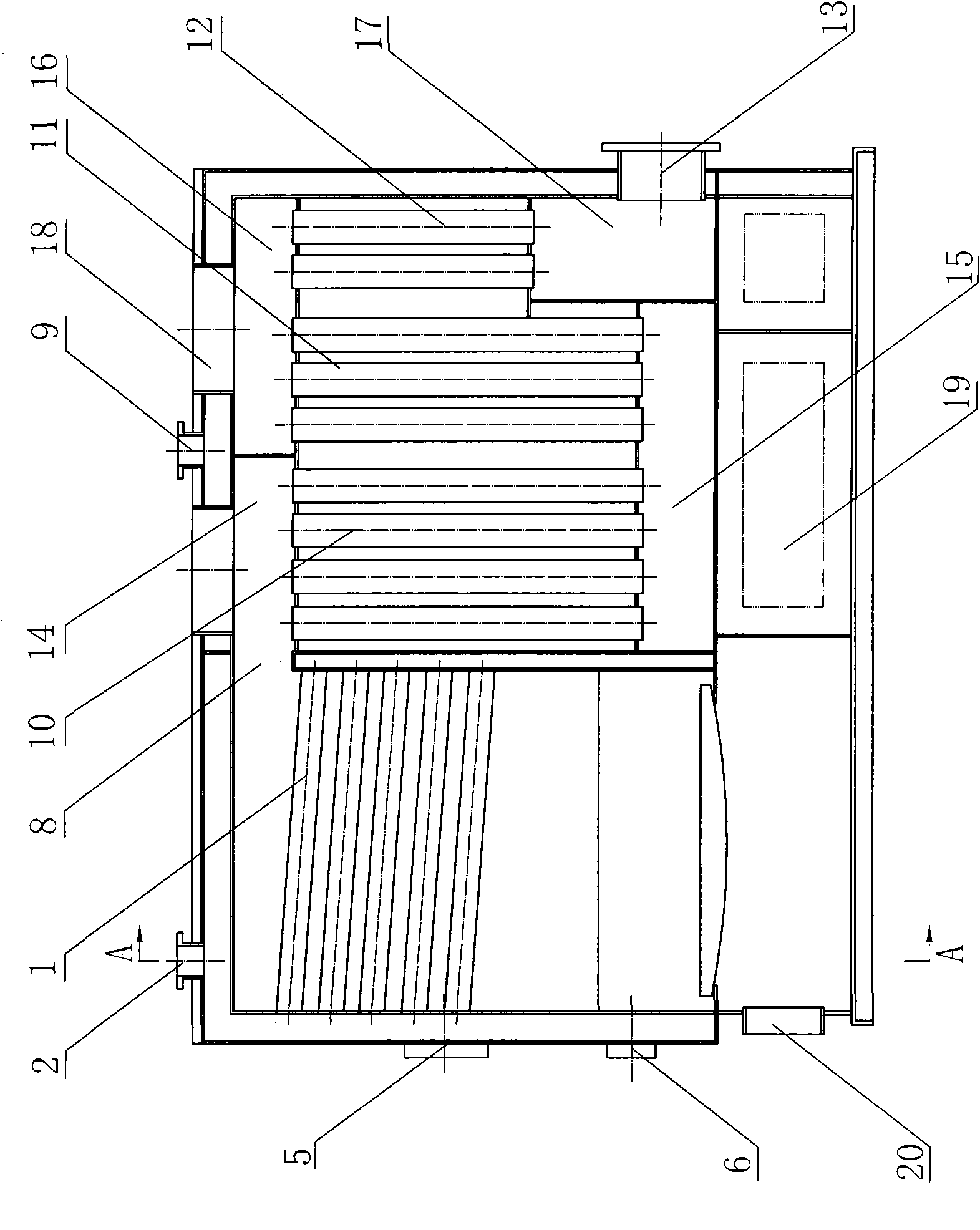

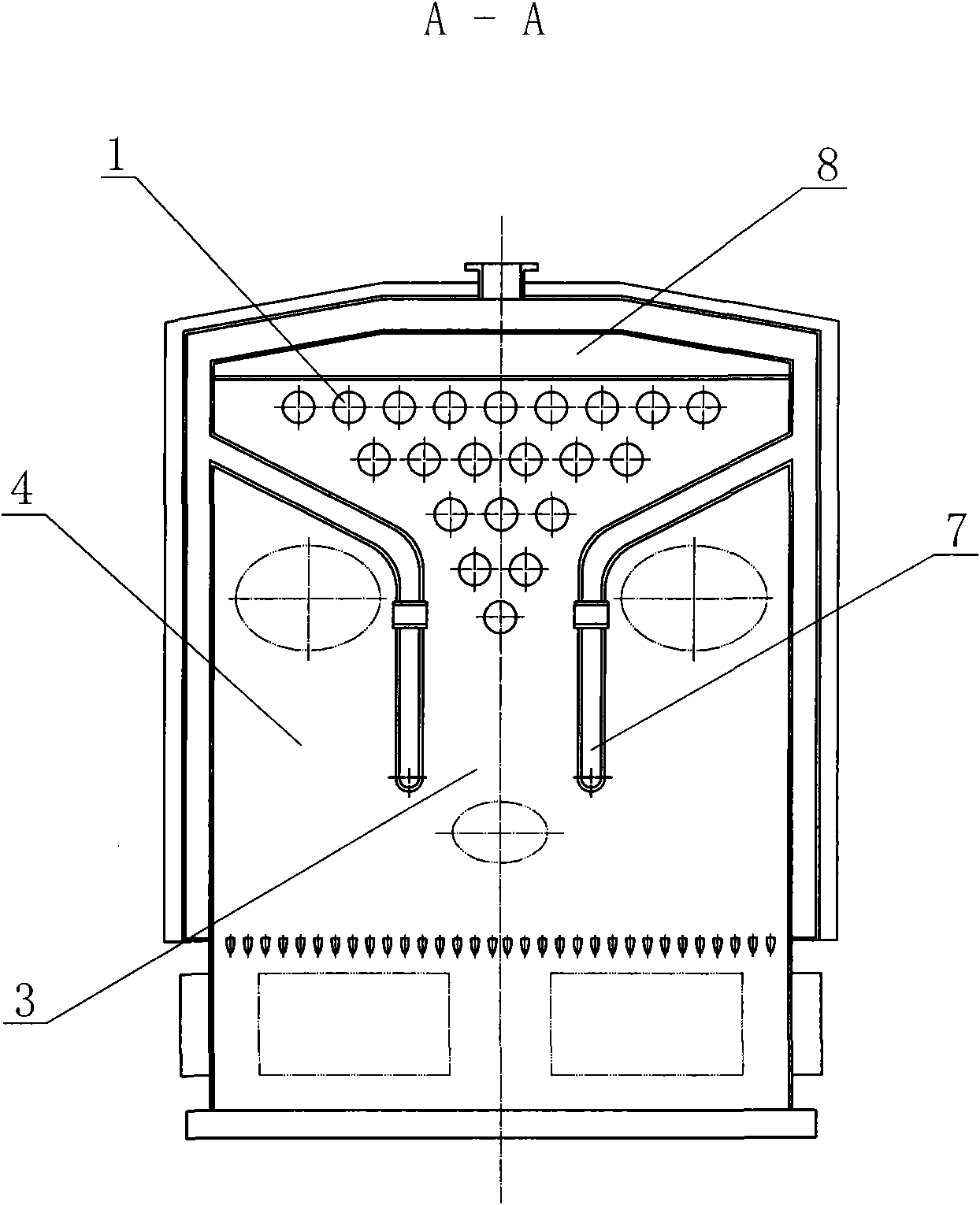

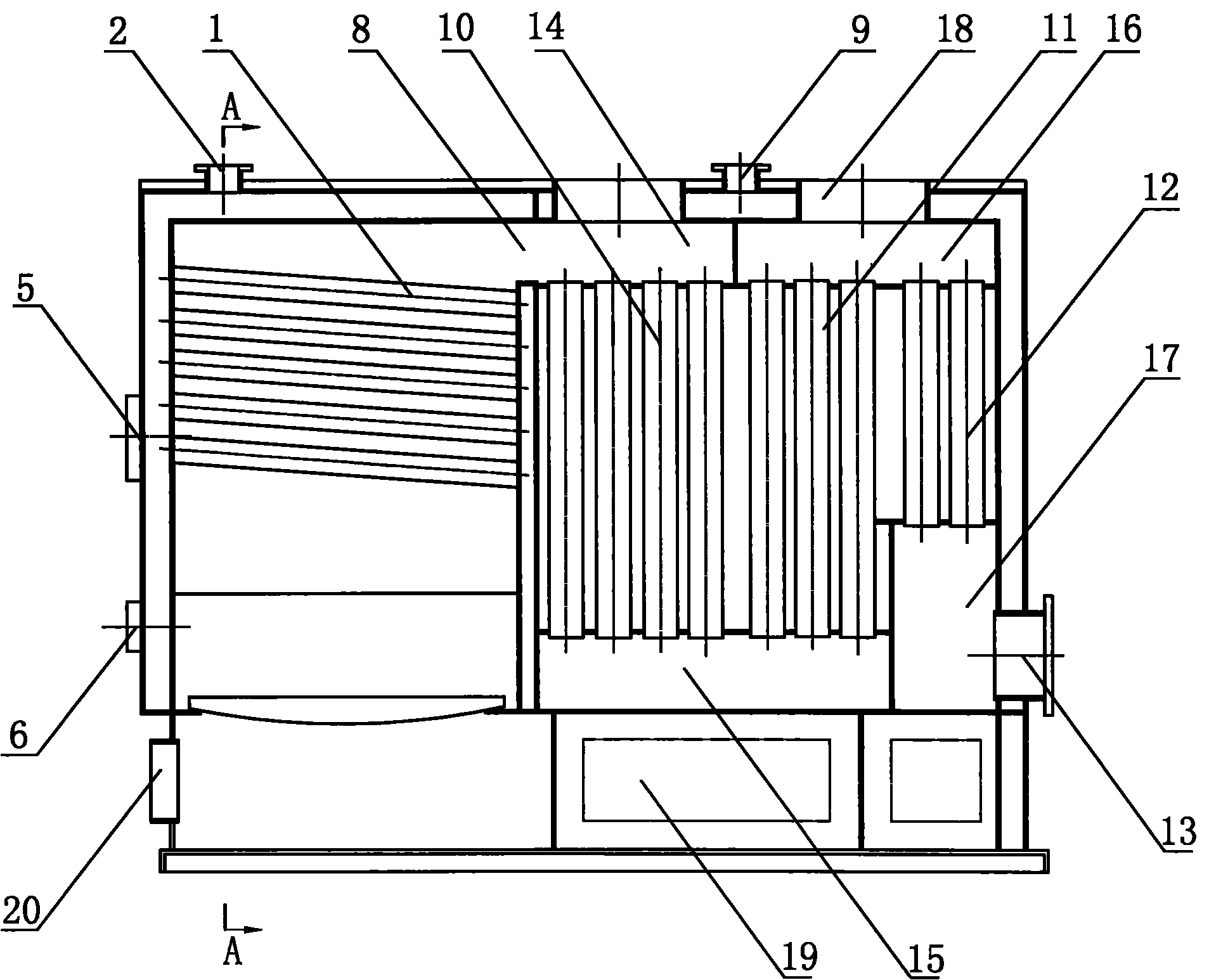

[0011] From figure 1 —— figure 2 It can be seen that the present invention is composed of a combustion chamber and a preheating chamber; the combustion chamber is composed of a convection pipe 1, a water outlet 2, a combustion zone 3, a coal storage area 4, and a water jacket of the combustion chamber; the water jacket of the combustion chamber is connected with a water outlet 2; The chamber water jacket communicates with the preheating water jacket through the transmission port; the water jacket partition wall 7 connected with the combustion chamber water jacket divides the combustion chamber into one to two combustion areas and one to four coal storage areas, and the combustion area 3 is connected to the coal storage area. Zone 4 is connected under the water jacket partition wall 7; there is a coal filling port 5 on the furnace wall at the upper end of the coal storage zone 4, and there is a slag cleaning port 6 on the furnace wall of the combustion zone 3; there are severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com