Candy and preparation method thereof

A confectionary and sucrose-free technology, which is applied in confectionary, confectionary industry, food science, etc., can solve the problems of high oil content and difficult coating of chocolate, and achieve the effect of rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Sweetener selection for sucrose-free chocolate

[0024] The sweetener is xylitol, sorbitol, maltitol, erythritol or isomalt. We compare the molding properties of sucrose-free chocolate.

[0025] sweetener

Embodiment 2

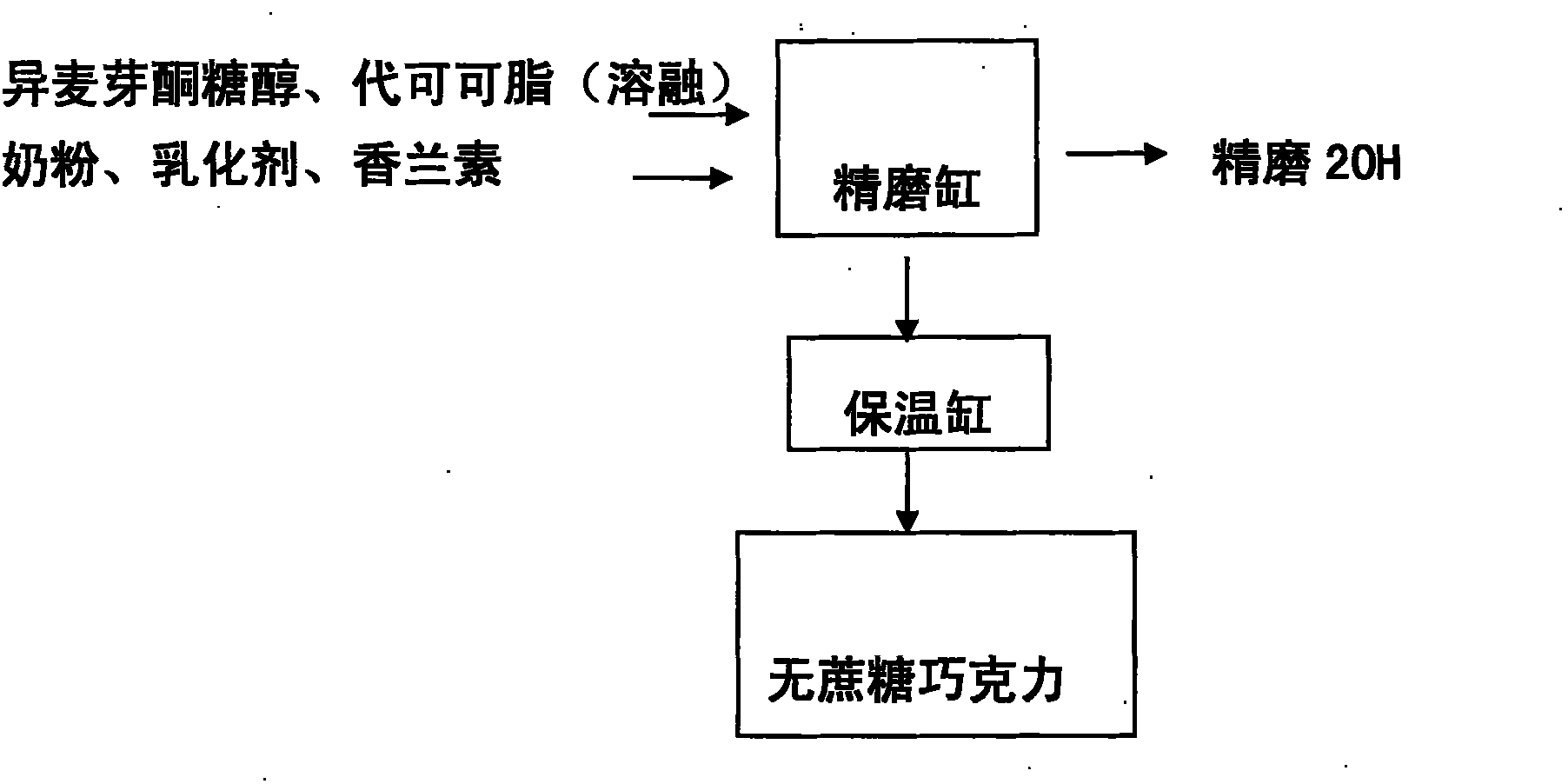

[0027] a. Prepare sugar-free chocolate:

[0028] Mix the sweetener, milk powder, cocoa butter, and vanilla and add it to the fine grinding tank containing chocolate. Heat the water bath to 70-75°C and start grinding. Grind for about 24 hours until the particle size of the chocolate is reduced to below 25 μm, and then cool it down. .

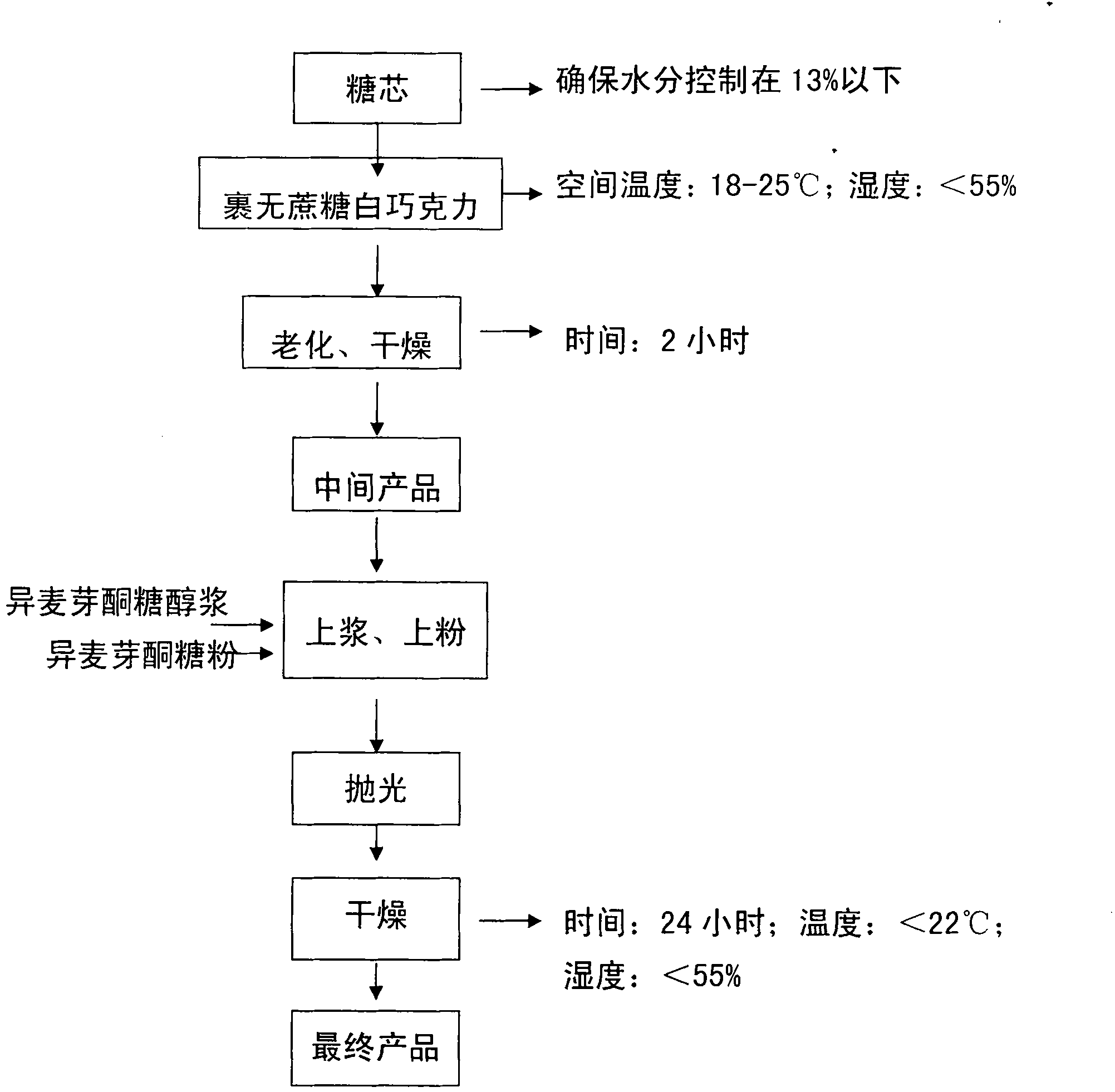

[0029] b. Preparation of sucrose-free chocolate-coated sucrose-free confectionery:

[0030] Slowly heat the above-mentioned sucrose-free chocolate and keep it warm at 45-50°C. The sucrose-free chocolate will remain in a flowing state, and then add the chocolate slowly to the rolling sugar core in the pot in the same way as the pulping method, and then turn on the fan to cool and set the shape That's it.

[0031] c. Coating:

[0032] Sugar-free chocolate is coated with gum arabic powder and sprayed with isomalt to complete the coating.

Embodiment 3

[0034] Candy A is an ordinary candy consisting of a gelled center, powdered sugar and a crispy coating

[0035] Candy B is the candy of the present invention

[0036]Candy C is m&m chocolate, which is a candy composed of sugar chocolate and sugar crispy coating. 100 candy consumers were randomly selected to taste three kinds of candies. 90% of candy consumers think that candy B has a smoother taste than candy A; 95% of candy consumers think that candy B has distinct layers and better taste than candy C. 89% of candy consumers like candy B because it tastes better than candy A and C.

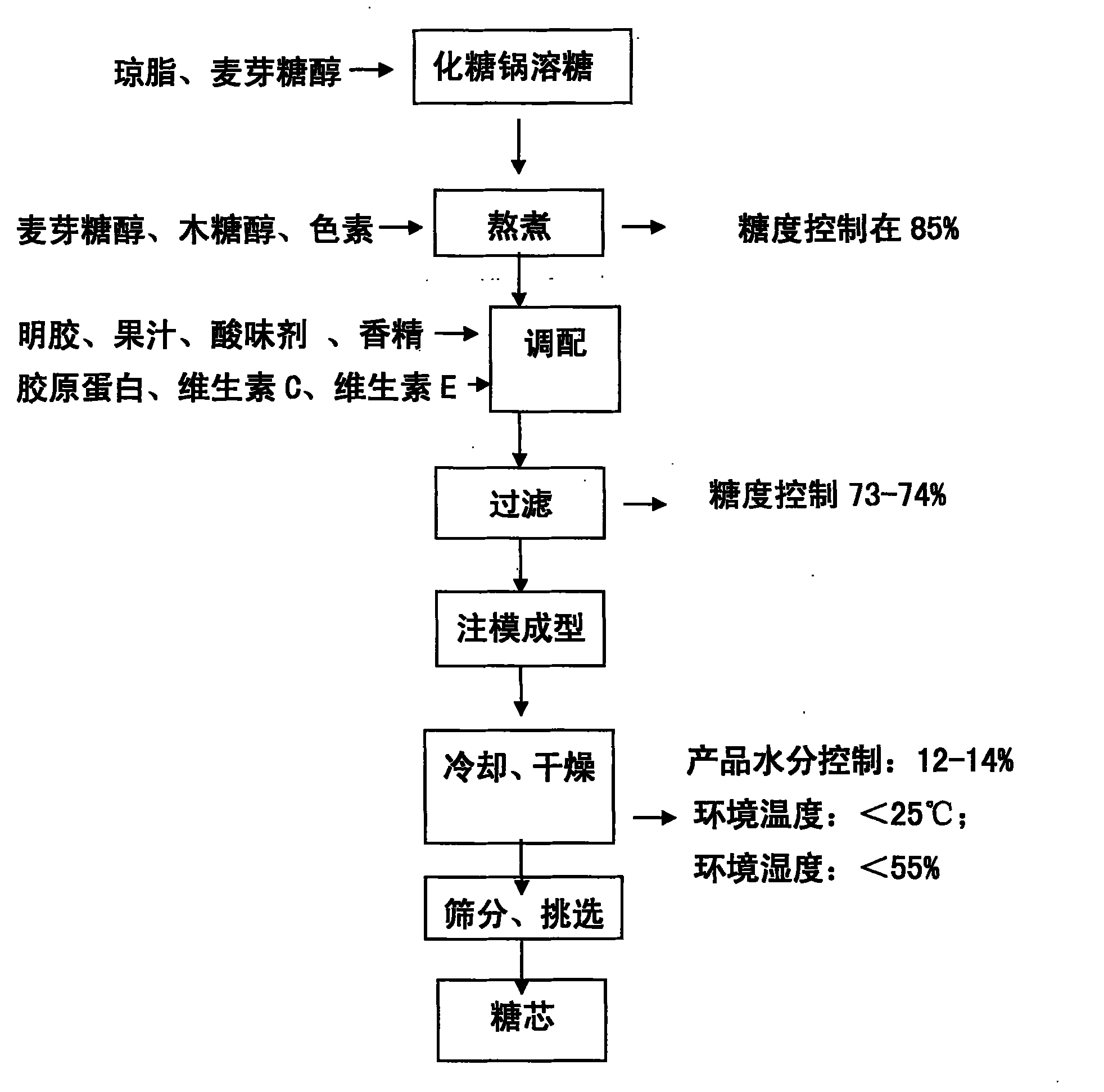

[0037] The technology of the sugar core is produced on the basis of the traditional gummy technology combined with a sugar-free formula. First, part of the maltitol is mixed with agar to facilitate its dispersion and dissolution, and then xylitol is added to cook to the specified sugar level. The key point is Brix control. The gel candy core adopts the process of sugar-free gel candy. Maltito...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com