Porous-structure composite material for IUD (Intrauterine Device) and producing method thereof

A porous structure and composite material technology, applied in medical science, surgery, etc., can solve problems such as side effects such as bleeding and pain that cannot be overcome, and achieve the effects of improving effective utilization, increasing porosity, and reducing bleeding and pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 25g of micron copper particles, 70g of medical grade low-density polyethylene (LDPE), and 5g of di-tert-butyl hydroquinone (DTBHQ), and use methods such as premixing, blending, injection or injection molding to prepare the The dense structure low-density polyethylene-based copper-containing composite material of the porogen; then use ethyl acetate as the extraction solvent to remove DTBHQ from the dense-structure low-density polyethylene-based copper-containing composite material in a Soxhlet extractor, and then The composite material after the extraction of the porogen is vacuum dried to remove ethyl acetate, and a porous structure composite material for intrauterine contraceptive devices is prepared.

Embodiment 2

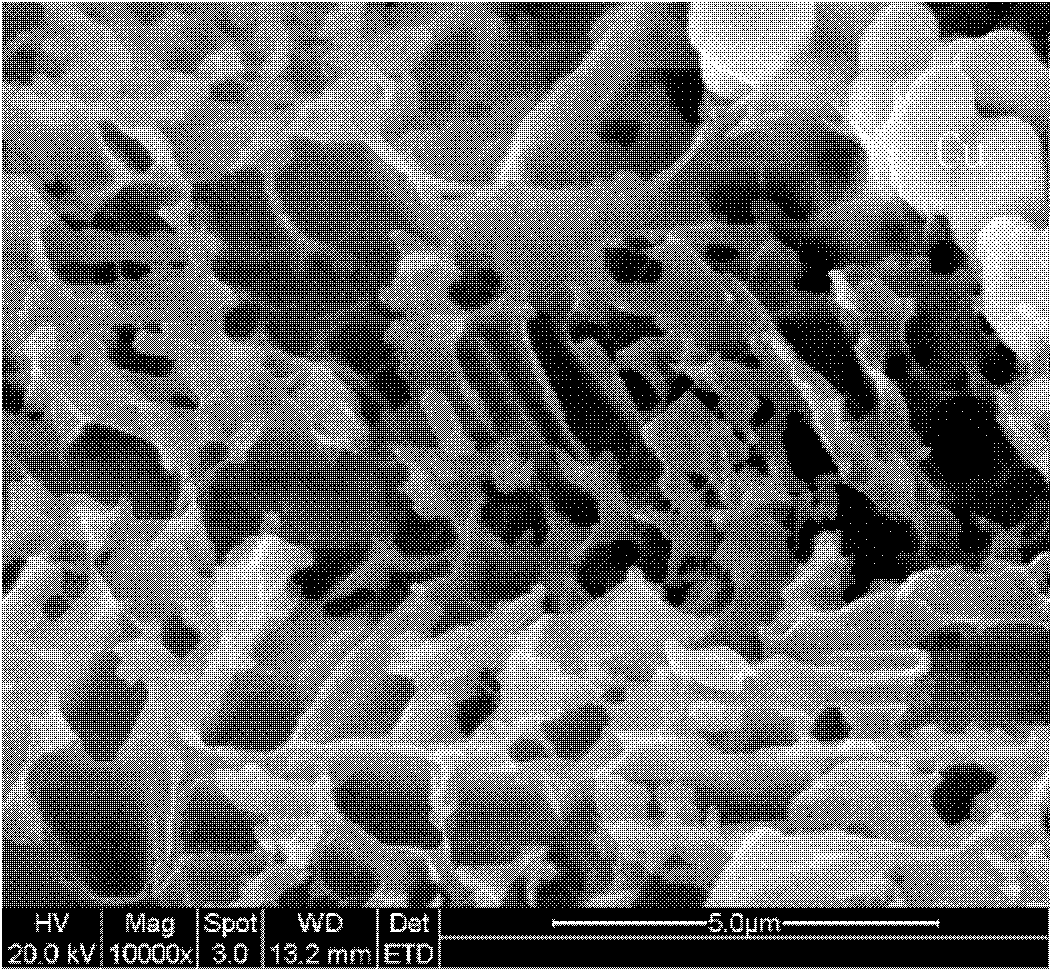

[0041] Weigh 20g of nano-copper particles, 65g of medical grade silicone rubber (SIR), 15g of tertiary butyl hydroquinone (TBHQ), and add a small amount of vulcanizing agent, using methods such as premixing, blending, injection molding or injection molding and vulcanization Firstly, a dense structure silicone rubber-based copper-containing composite material containing a porogen is prepared; then acetone is used as an extraction solvent to remove the TBHQ from the dense structure silicone rubber-based copper-containing composite material by immersion in acetone for a long time, and then After the porogen is extracted, the composite material is vacuum dried to remove the acetone, and a porous structure composite material for IUD is prepared.

[0042] Examples 3-25 are all prepared by a method similar to Example 1 or Example 2, wherein the prepared porous structure composite material for intrauterine contraceptive device is the original composition and the extraction solvent used an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap