Wide rim deep LIP automobile aluminium alloy wheel casting mould filling exhaust method

A technology of aluminum alloy wheel hub and exhaust method, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve problems such as protruding air holes, and achieve the effects of convenient use, low cost, and remarkable exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation

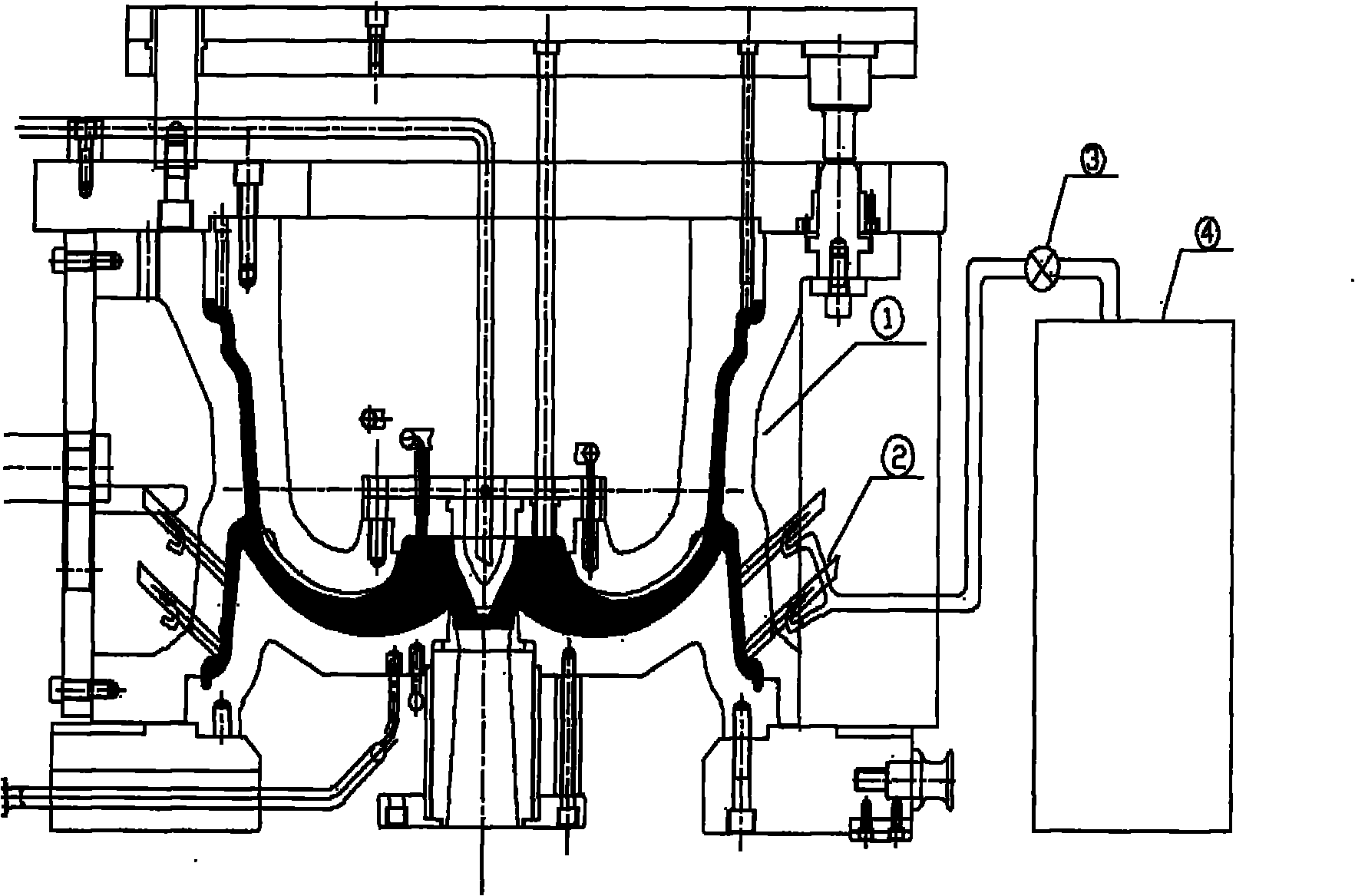

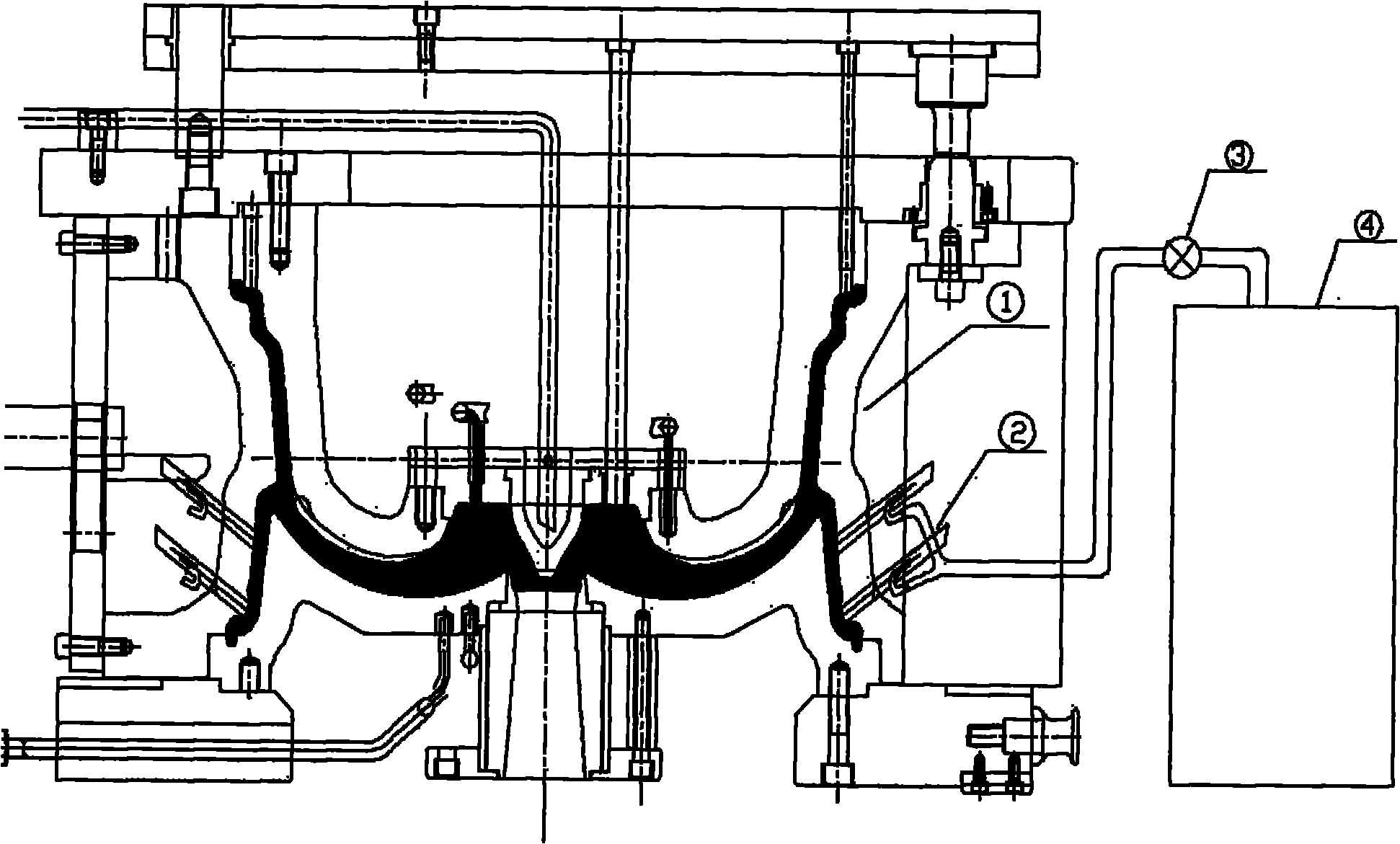

[0009] Such as figure 1 As shown, a wide rim deep LIP automotive aluminum alloy wheel hub casting filling exhaust method, including side mold 1, exhaust plug 2, compressed air control valve 3, low pressure casting system control cabinet 4, exhaust plug 2 is set on the side At the position of mold 1, install 8 exhaust plugs in this area according to the diameter of the hub. One end of the exhaust plug 2 is connected to the compressed air control valve 3, and the compressed air control valve 3 is connected to the control cabinet 4 of the low-pressure casting system. The compressed air The air pressure parameter is 280Kpa. Open the compressed air control valve when the aluminum liquid is about to start filling, and remove the gas inside the mold cavity through the exhaust plug according to the Berlek principle, so that the mold cavity is under a slight negative pressure during the filling process; The exhaust time of the air plug is 15 seconds. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com