Lead-free calcium barium zirconate titanate piezoelectric ceramics and preparation method thereof

A barium calcium zirconate titanate, lead-free piezoelectric technology, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve environmental pollution and other problems, achieve great application potential and preparation process Stable, reliable, performance-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

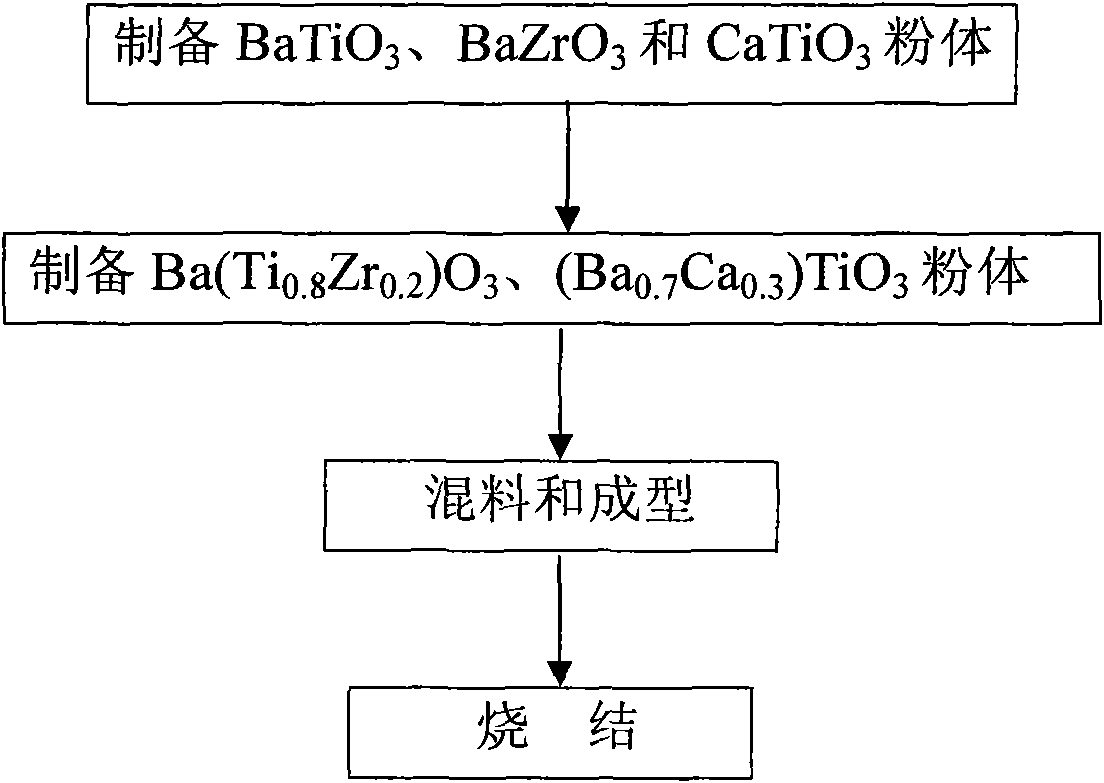

Method used

Image

Examples

Embodiment 1

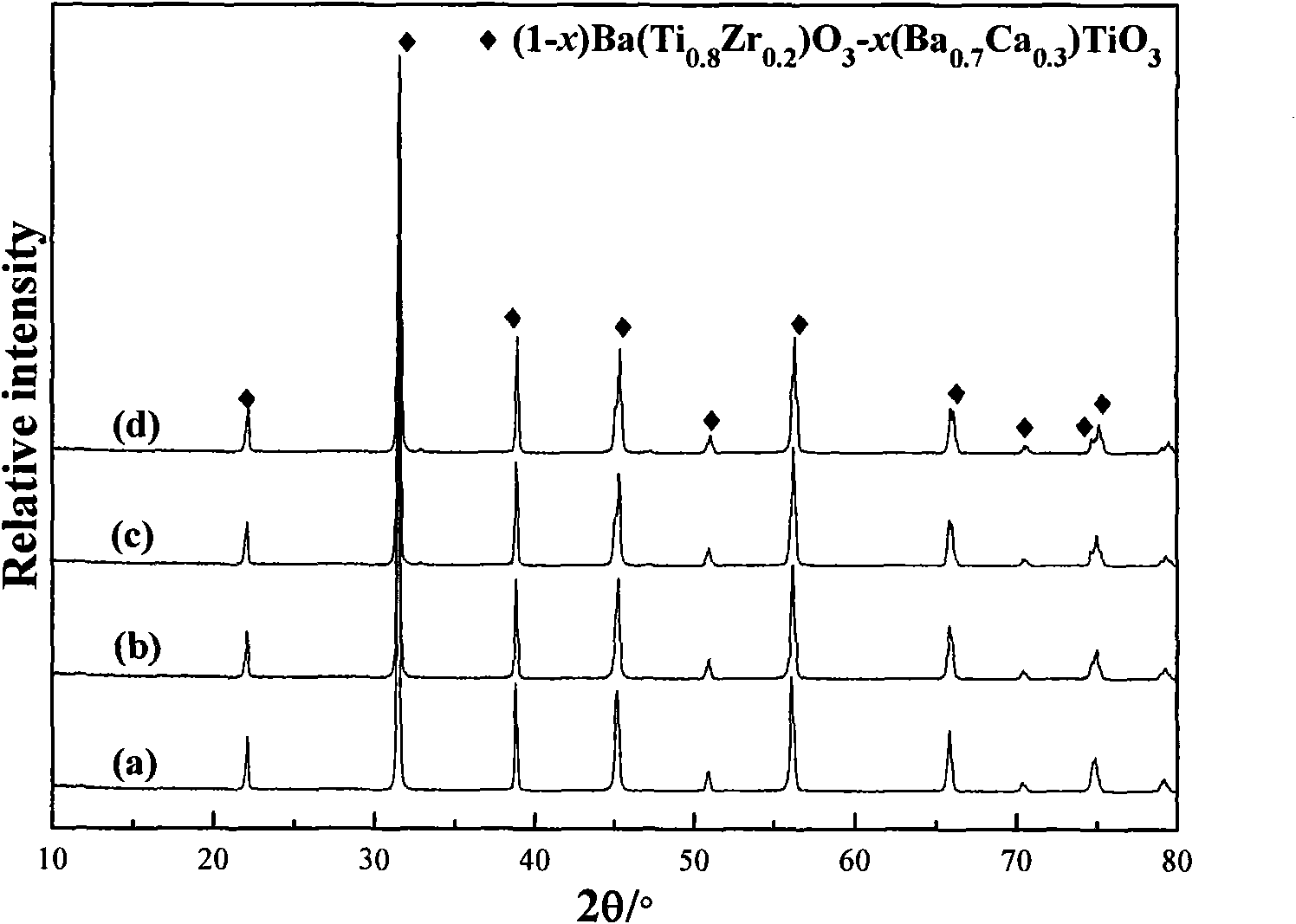

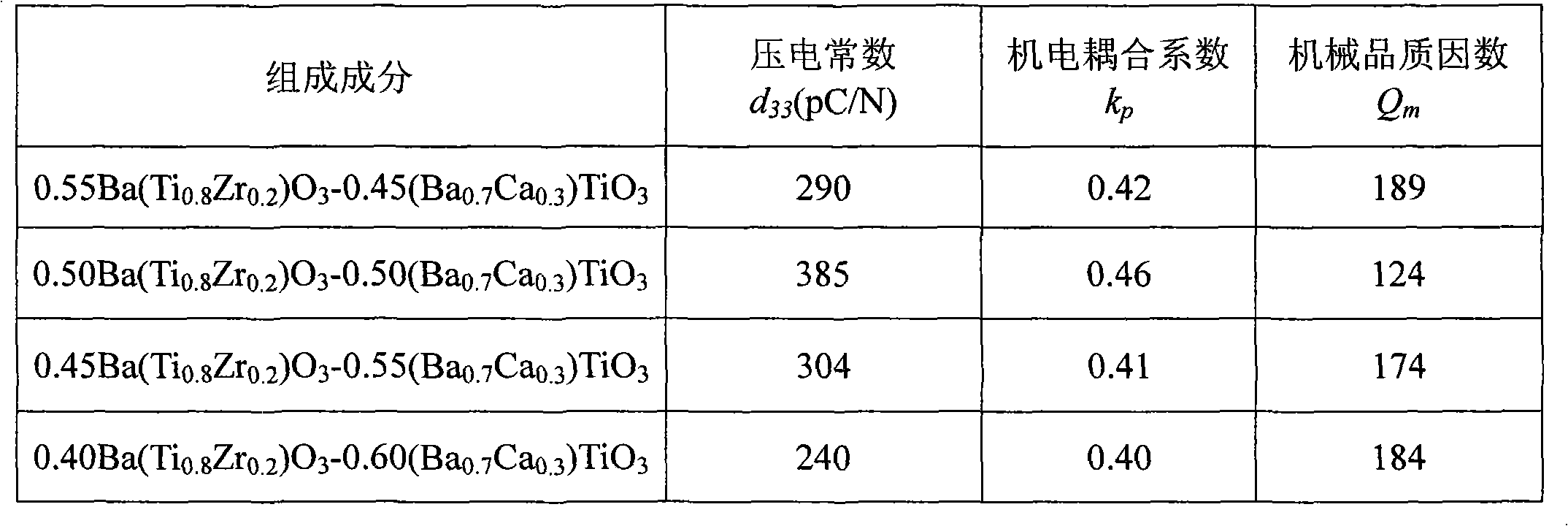

[0018] The composition of this example is (1-x)Ba(Ti 0.8 Zr 0.2 )O 3 -x(Ba 0.7 Ca 0.3 )TiO 3 , where x=0.45.

[0019] The first step is to prepare BaTiO 3 , BaZrO 3 and CaTiO 3 powder; preparation of BaTiO 3 Powder: let n represent the amount of substance to analyze pure BaCO 3 、TiO 2 As raw material, according to n(BaCO 3 ):n(TiO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol medium for 12h, drying the powder at 50°C for 14h, pre-calcining at 1100°C for 4h to obtain BaTiO 3 powder; preparation of BaZrO 3 Powder: Analytical pure BaCO 3 , ZrO 2 As raw material, according to n(BaCO 3 ):n(ZrO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol medium for 12h, after drying the powder at 50°C for 14h, pre-calcining at 1100°C for 4h, to obtain BaZrO 3 powder; preparation of CaTiO 3 Powder: to analyze pure CaCO 3 、TiO 2 As raw material, according to n(CaCO 3 ):n(TiO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol med...

Embodiment 2

[0025] The composition of this example is (1-x)Ba(Ti 0.8 Zr 0.2 )O 3 -x(Ba 0.7 Ca 0.3 )TiO 3 , where x=0.50.

[0026] The first step is to prepare BaTiO 3 , BaZrO 3 and CaTiO 3 powder; preparation of BaTiO 3 Powder: let n represent the amount of substance to analyze pure BaCO 3 、TiO 2 As raw material, according to n(BaCO 3 ):n(TiO 2 )=1:1 Weighing the ingredients, ball milling in absolute ethanol medium for 12h, drying the powder at 60°C for 8h, pre-calcining at 1200°C for 2h, to obtain BaTiO 3 powder; preparation of BaZrO 3 Powder: Analytical pure BaCO 3 , ZrO 2 As raw material, according to n(BaCO 3 ):n(ZrO 2 )=1:1 Weighing ingredients, ball milling in absolute ethanol medium for 12h, after drying the powder at 60°C for 8h, pre-calcining at 1200°C for 2h, to obtain BaZrO 3 powder; preparation of CaTiO 3 Powder: to analyze pure CaCO 3 、TiO 2 As raw material, according to n(CaCO 3 ):n(TiO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol me...

Embodiment 3

[0032] The composition of this example is (1-x)Ba(Ti 0.8 Zr 0.2 )O 3 -x(Ba 0.7 Ca 0.3 )TiO 3 , where x=0.55.

[0033] The first step is to prepare BaTiO 3 , BaZrO 3 and CaTiO 3 powder; preparation of BaTiO 3 Powder: let n represent the amount of substance to analyze pure BaCO 3 、TiO 2 As raw material, according to n(BaCO 3 ):n(TiO 2 )=1:1 Weighing the ingredients, ball milling in absolute ethanol medium for 12h, drying the powder at 50°C for 20h, pre-calcining at 1000°C for 6h to obtain BaTiO 3 powder; preparation of BaZrO 3 Powder: Analytical pure BaCO 3 , ZrO 2 As raw material, according to n(BaCO 3 ):n(ZrO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol medium for 12h, after drying the powder at 50°C for 20h, pre-calcining at 1000°C for 6h, to obtain BaZrO 3 powder; preparation of CaTiO 3 Powder: to analyze pure CaCO 3 、TiO 2 As raw material, according to n(CaCO 3 ):n(TiO 2 )=1:1 Weighing ingredients, ball milling in anhydrous ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com