Deepwater single-wall steel overhead bin cofferdam and construction method thereof

A technology of steel hanging box and deep water single, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of slow progress of the project, the need for cranes, and the difficulty of construction, so as to reduce the difficulty of construction, the construction process is simple, and the construction period is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

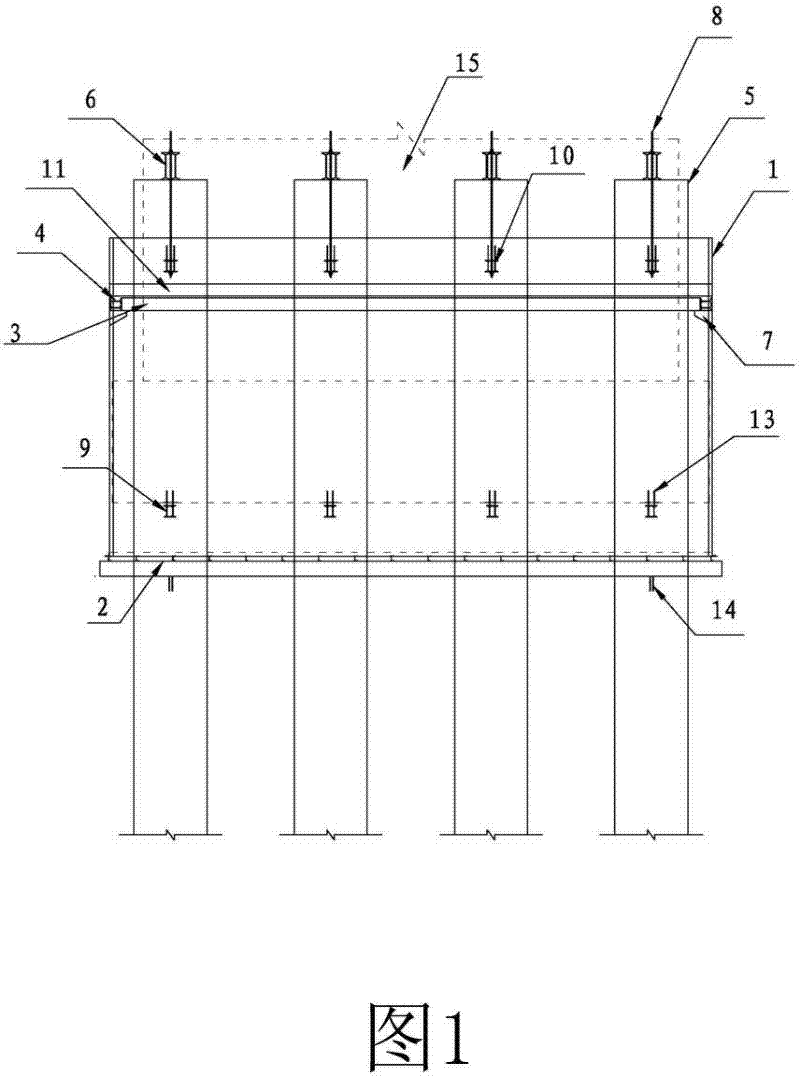

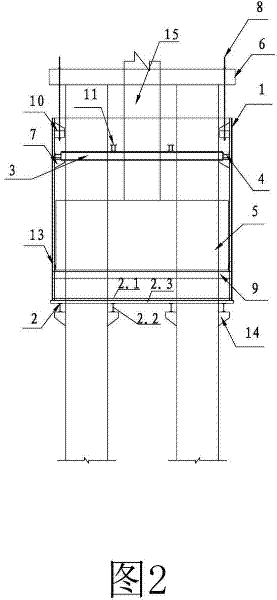

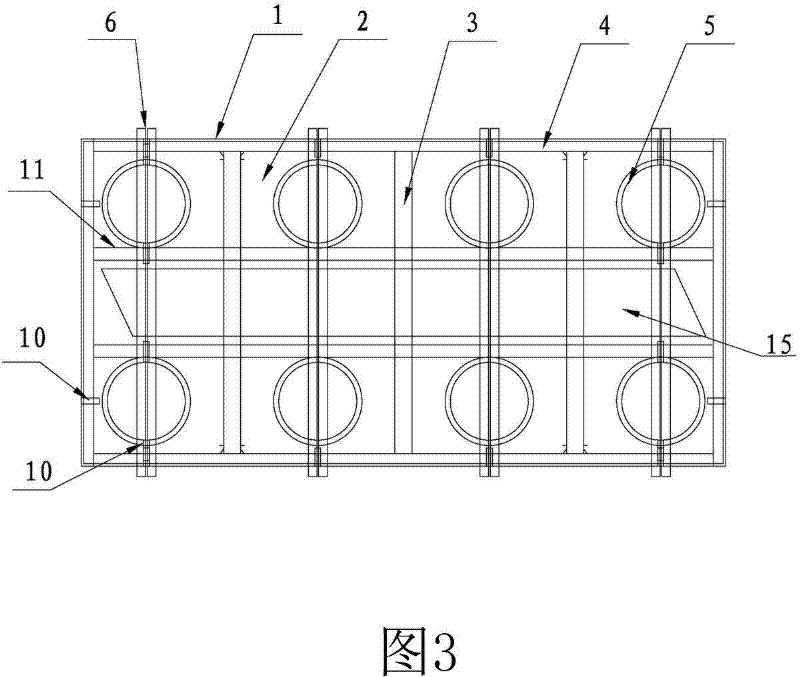

[0038] Examples see Figure 1 to Figure 5 As shown, a deep-water single-wall steel hanging box cofferdam is enclosed around the steel casing 5 of the proposed pile foundation 15 in the deep-water area, including an enclosure system, an internal support system and a suspension system. The enclosure system is a side enclosure Rectangular box shape surrounded by the protection system 1 and the bottom protection system 2, the side protection system includes side panels 1.1, horizontal back corrugations 1.2, vertical back corrugations 1.3 and angle steel 1.4, bottom enclosure system bottom plate 2.1, longitudinal back corrugations 2.2 and Horizontal back flute 2.3, the inner support system is supported on the inner side of the side plate, and the hanging system is connected to the side enclosure system. The hanging system is composed of lifting corbels 10, upper beams 6, lower beams 9 and booms 8. The corbel 10 is welded on the inner side of the side plate, the upper beam 6 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com