Horizontal multi-shaft disc dryer

A disc dryer and drying technology, used in dryers, drying solid materials, heating to dry solid materials, etc., can solve the problems of small heat transfer area and low thermal efficiency, and achieve increased heat transfer area, improve thermal efficiency, The effect of size and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

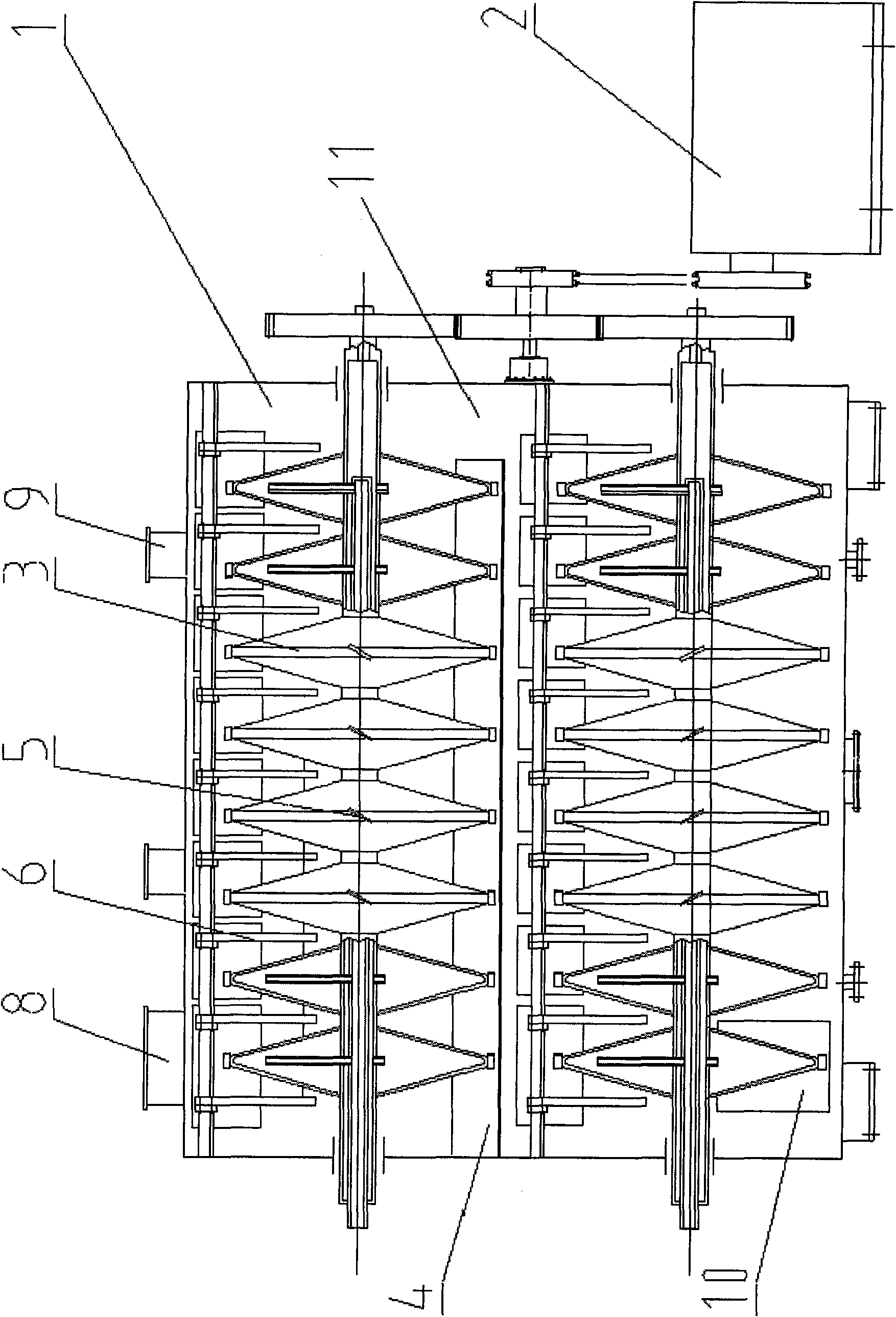

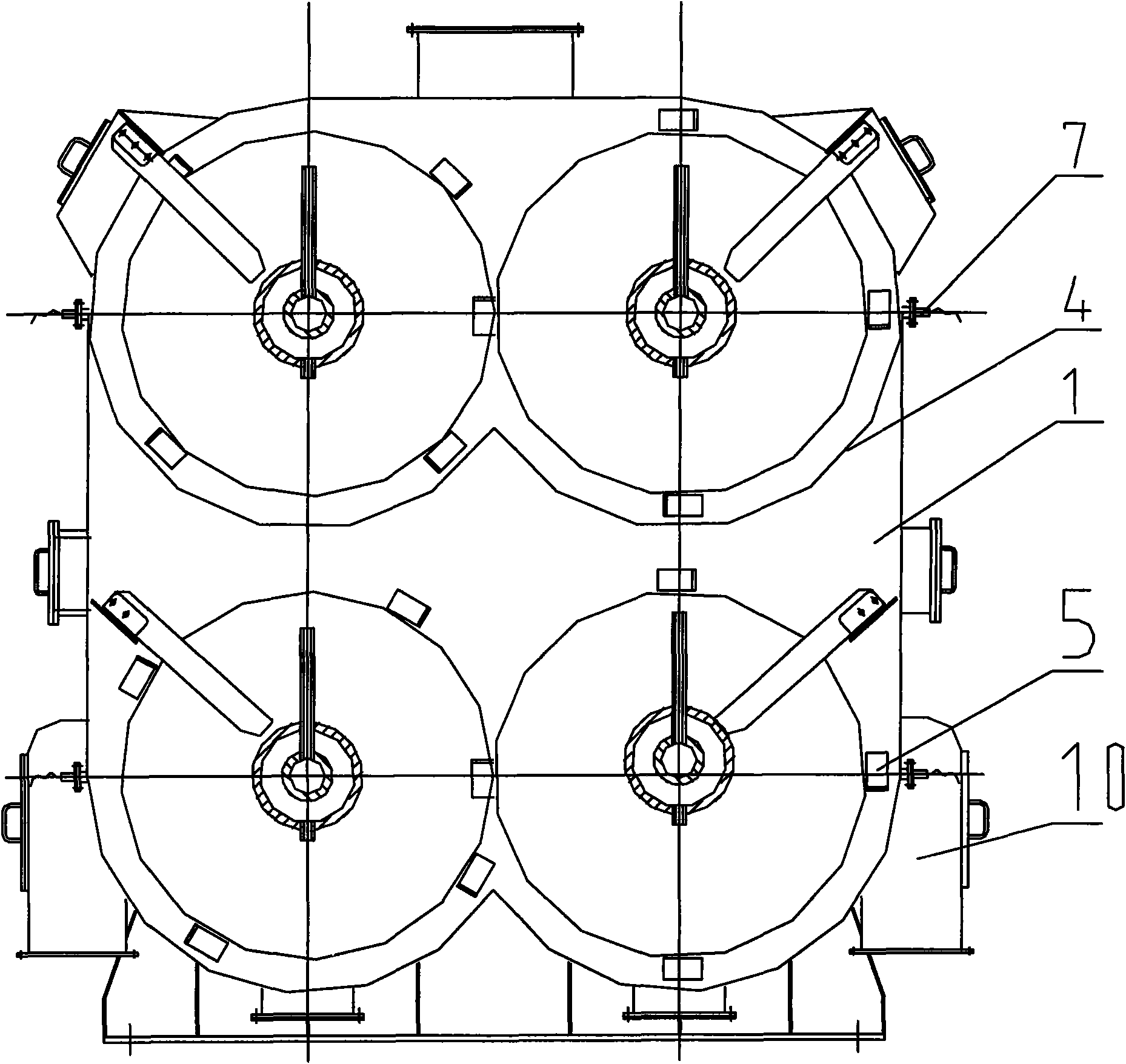

[0032] See attached Figure 1-2 , a horizontal multi-axis disc dryer comprising: a housing 1 provided with a feed port 8, a discharge port 10 and an exhaust port 9; the first and second drying layer units, including a Drying disc shaft 3, the drying disc installed on the drying disc shaft 3 and the pushing plate 5 installed on the outer circumference of the drying disc; and the power transmission mechanism 2 for rotating the drying disc shaft 3; wherein, The first and second dry layer units are installed in the housing 1, and a spacer 4 and a material channel 11 adjacent to the spacer 4 are arranged between the first and second dry layer units, so as to The material to be dried passes through the feeding port 8 , the first drying layer unit, the material channel 11 , and the second drying layer unit to the discharge port 10 in sequence.

[0033] Preferably, the horizontal multi-shaft disc dryer may further include a scraper 6 installed between each drying disc for scraping of...

Embodiment 2

[0046] The structure of the horizontal multi-shaft disc dryer in this embodiment is basically the same as that in Embodiment 1, and the similarities are omitted here, and the differences will be mainly described below.

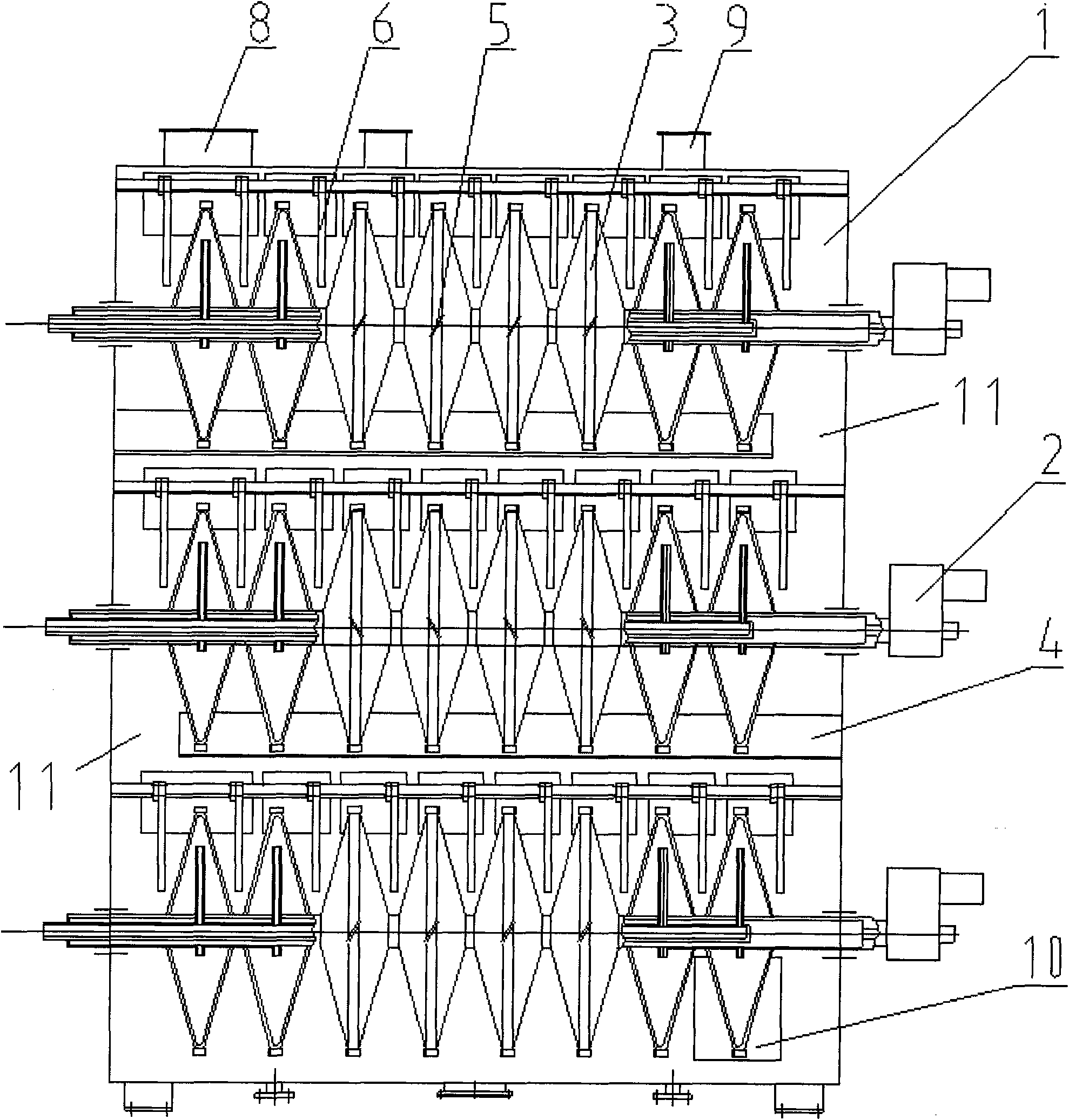

[0047] See attached image 3 And attached Figure 4 , the horizontal multi-shaft disc dryer also includes one or more drying layer units, and spacers 4 and material passages 11 adjacent to the spacers are arranged between all drying layer units, and the material passages 11 alternately They are arranged on the right and left sides of the corresponding spacer so that the material to be dried can pass through the drying layer unit and reach the discharge port 10 smoothly.

[0048] Preferably, the horizontal multi-shaft disc dryer may include: a housing 1, 6 power transmission mechanisms 2, 6 drying disc shafts 3, 2 spacers 4, a pusher plate 5 and a scraper 6, wherein, 6 drying disc shafts 3 are stacked up and down two or two to form three layers (upper, middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com