Key-press input module

A technology of input modules and buttons, applied in simulators, instruments, computer control, etc., can solve the problems of complex circuits, inconvenient use, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

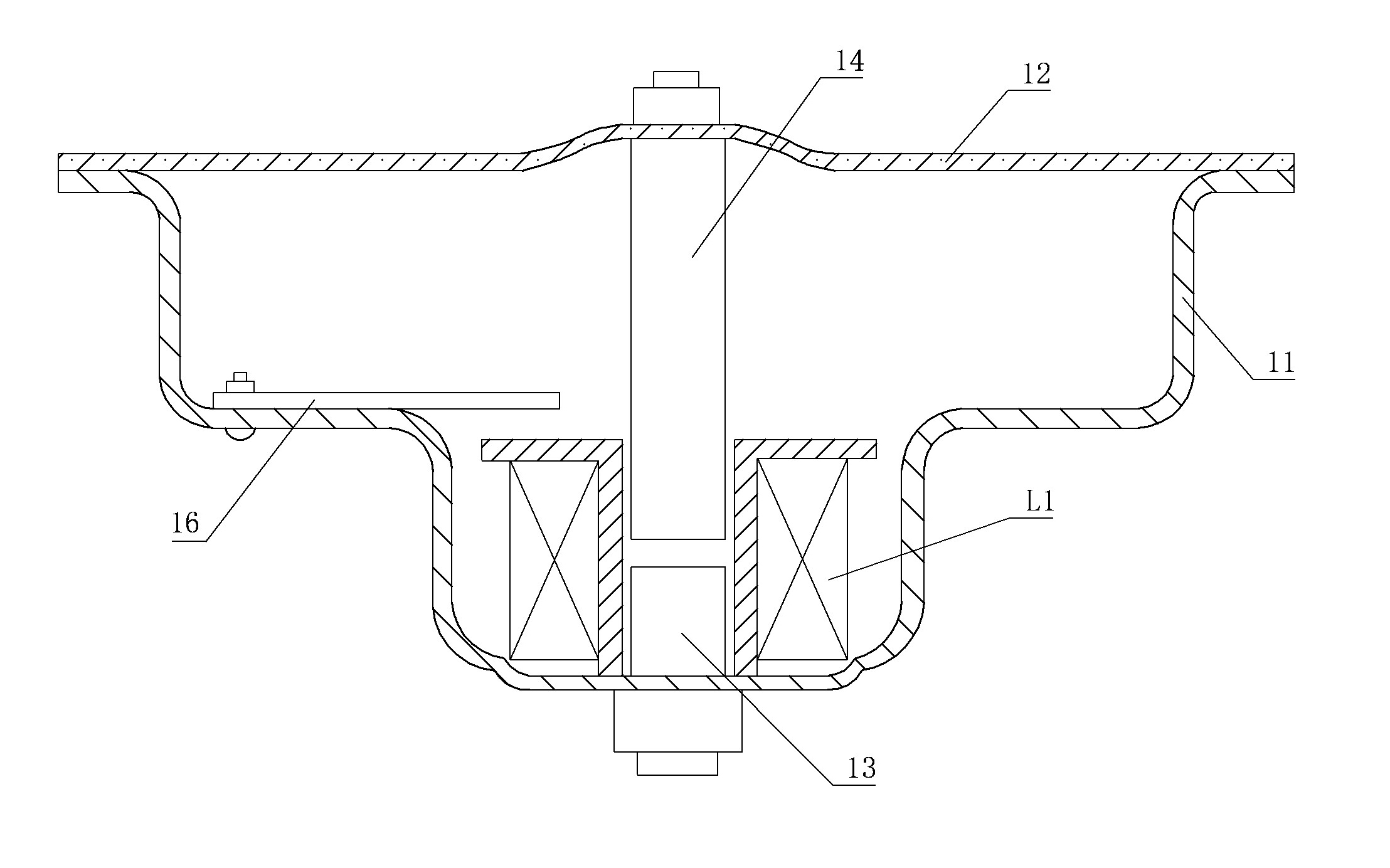

Embodiment 1

[0054] Embodiment 1: See Figure 1, Figure 5 , in the figure, the electric horn intelligent control device includes a bowl-shaped bottom shell 11, a static iron core 13, a moving iron core 14, a coil L1, a vibrating membrane 12, and a control circuit. The vibrating membrane 12 covers the top of the bowl-shaped bottom shell 11. The iron core 13 is fixed in the middle of the bowl-shaped bottom shell 11, and a moving iron core 14 is arranged above the static iron core 13. The moving iron core 14 is fixedly connected with the middle part of the vibrating membrane 12, and the coil L1 is set on the static iron core 13 and Outside the moving iron core 14, the circuit board 16 containing the control circuit is fixed on the inner wall of the bowl-shaped bottom shell 11. The control circuit contains a micro-processing module 1, a power supply module 2, a coil drive module 3, a key input module 4, and a vibrating membrane vibration The signal detection module 5, the microprocessing modul...

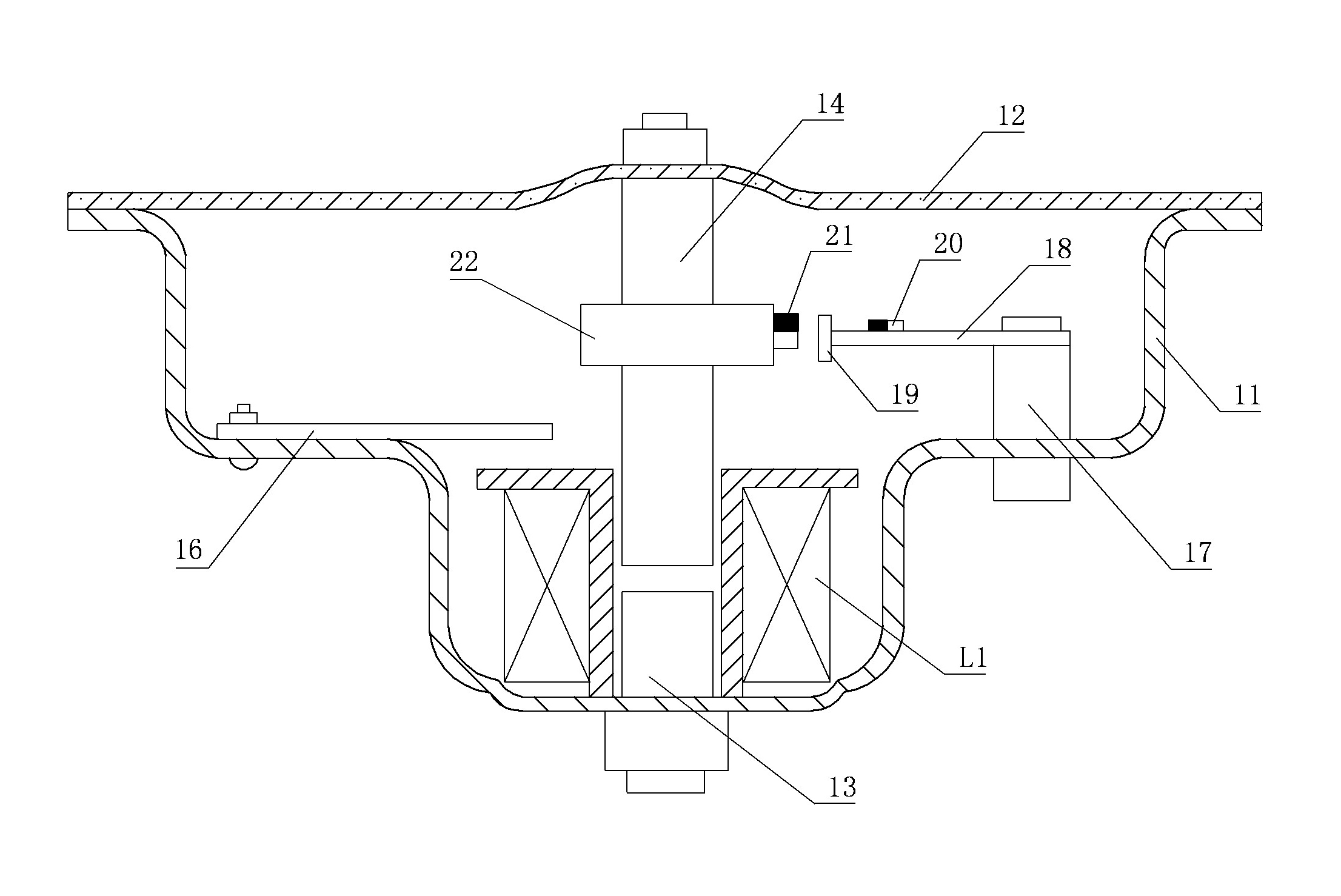

Embodiment 2

[0079] Embodiment 2: Referring to Fig. 2 and Fig. 6, the numbers in the figure are the same as those in Embodiment 1, and the representative meanings are the same, and the working process is basically the same, and the similarities will not be repeated. The difference is: the vibration signal detection of the vibrating membrane The module 5 contains a linear Hall sensor 19, the output terminal of the linear Hall sensor 19 is connected to the analog signal input terminal AN2 of the microcontroller U1, the source of the field effect transistor V2 is grounded, and a pillar 17 is vertically fixed on the inner wall of the bowl-shaped bottom case 11 , a bracket 18 is horizontally fixed on the pillar 17, a linear Hall sensor 19 is installed at one end of the bracket 18 and the linear Hall sensor 19 is close to the moving iron core 14, and the outer surface of the moving iron core 14 is provided with a fixed card 22, on which the fixed card 22 A permanent magnet 21 corresponding to the...

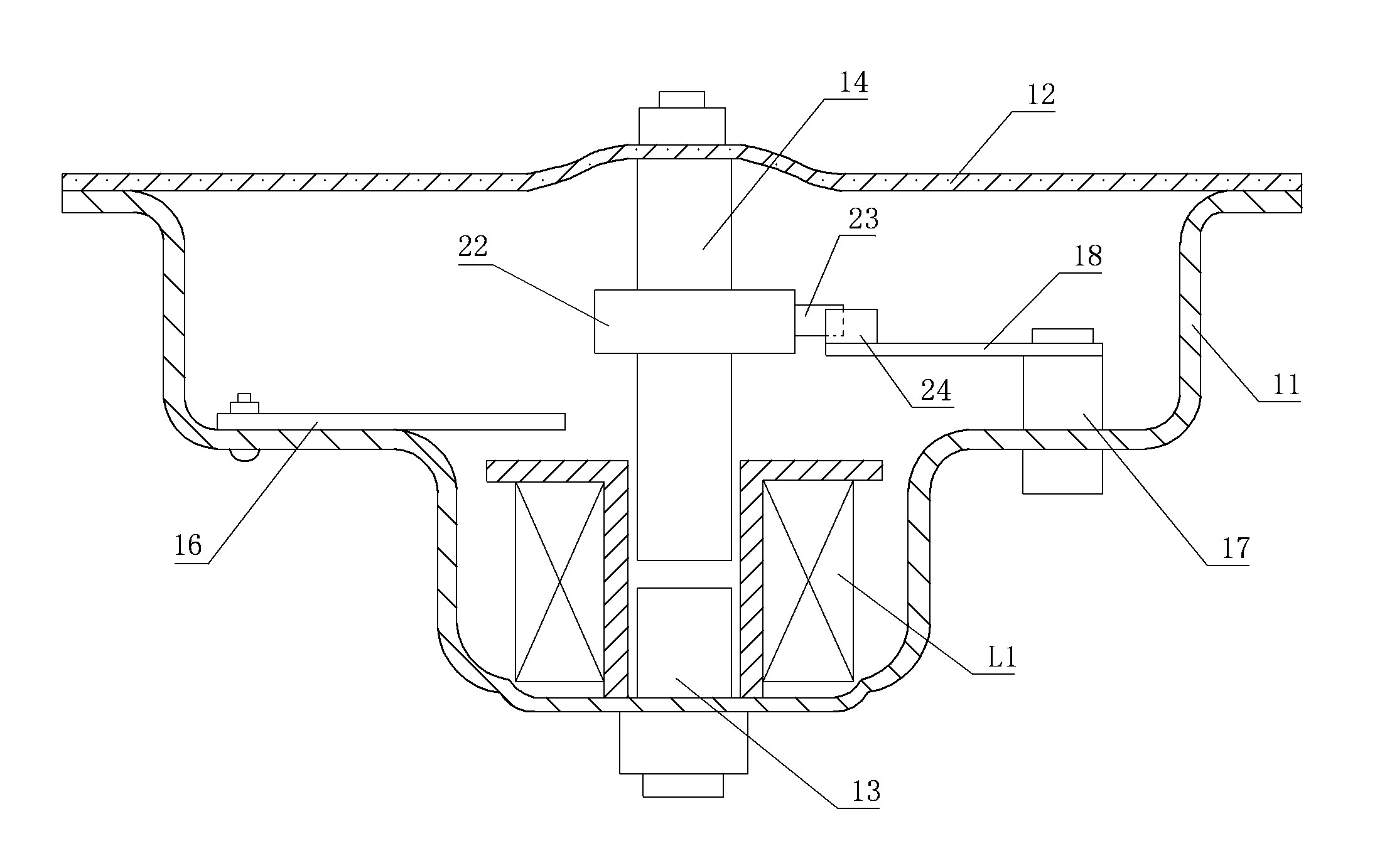

Embodiment 3

[0082] Embodiment Three: See Figure 3, Figure 7 , the numbers in the figure are the same as those in Embodiment 1, the representative meanings are the same, and the working process is basically the same. The photocoupler 24 contains emitting diode L2 and linear illuminance sensor U4, the anode of emitting diode L2 is connected to the power supply terminal of the single-chip microcomputer U1 through the resistor R10, the + terminal of the linear illuminance sensor U4 is connected to the power supply terminal of the single-chip microcomputer U1 through the resistor R11, and the linear illuminance sensor The + terminal of U4 is also connected to the analog signal input terminal AN2 of the single-chip microcomputer U1, a pillar 17 is vertically fixed on the inner wall of the bowl-shaped bottom shell 11, and a support 18 is fixed horizontally on the support 17, and a linear photocoupler 24 is installed on one end of the support 18 And the linear photocoupler 24 is close to the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com