Vehicle circuit breaker production monitoring system and method

A technology of monitoring system and circuit breaker, applied in circuits, electrical components, electrical program control, etc., can solve problems such as untimely understanding of processing information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

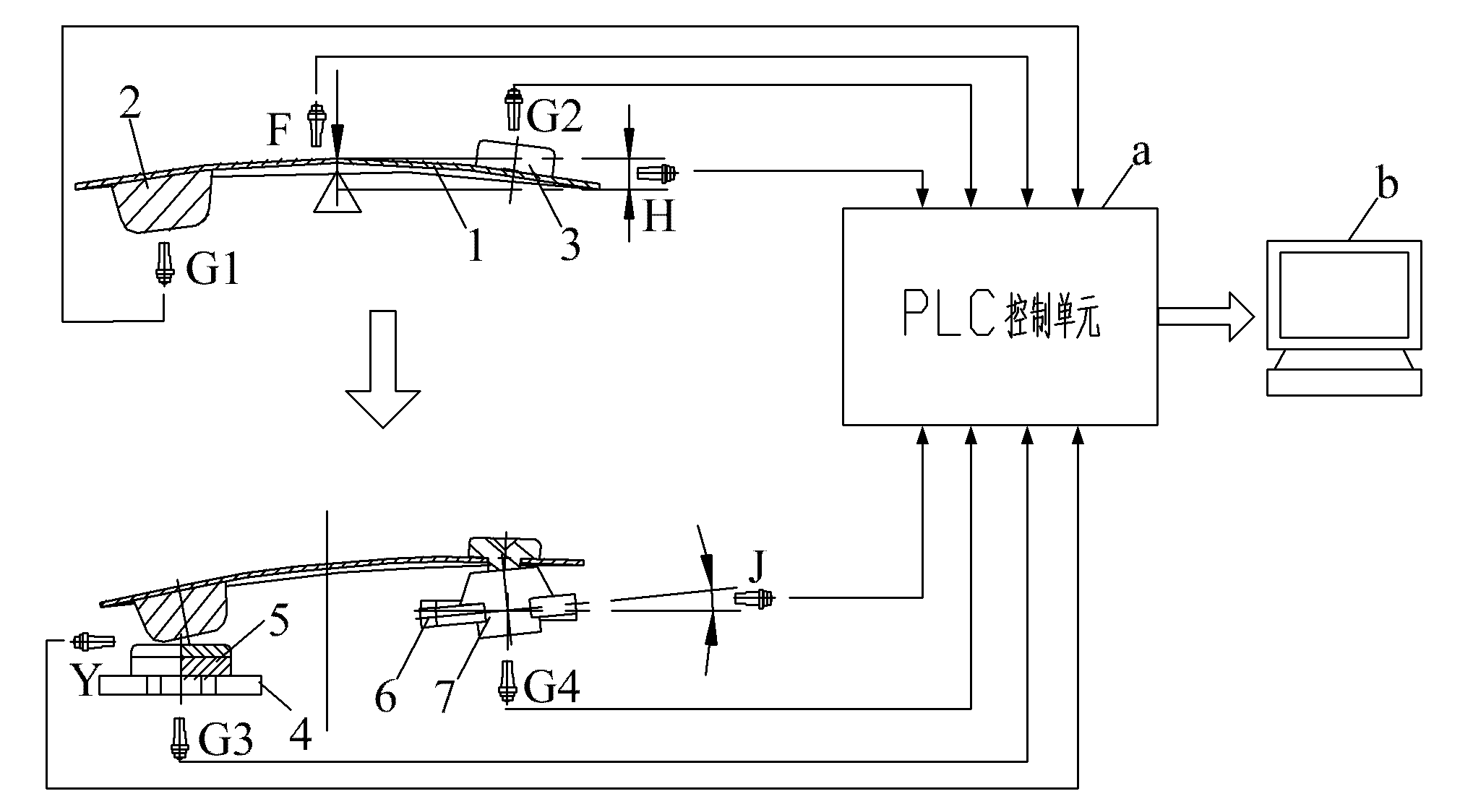

[0031] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is that the vehicle circuit breaker production monitoring system includes a sensor group, a PLC control unit a and a computer b;

[0032] The sensor group is composed of a pressure sensor F, a moving contact sensor G1, a rivet sensor G2, a height sensor H, an angle sensor J, a static contact sensor G3, a welding chip sensor G4 and a preload sensor Y;

[0033] The pressure sensor F is used to monitor the pressure on the memory metal sheet 1 of the vehicle circuit breaker during processing to form an arc;

[0034] The moving contact sensor G1 is used to monitor whether the moving contact 2 is welded at the position set by the memory metal sheet 1 of the vehicle circuit breaker, and send the monitoring result to the PLC control unit a;

[0035] The rivet sensor G2 is used to monitor whether the rivet 3 is welded at the position set by the memory metal sheet 1 of the vehicle circui...

specific Embodiment approach 2

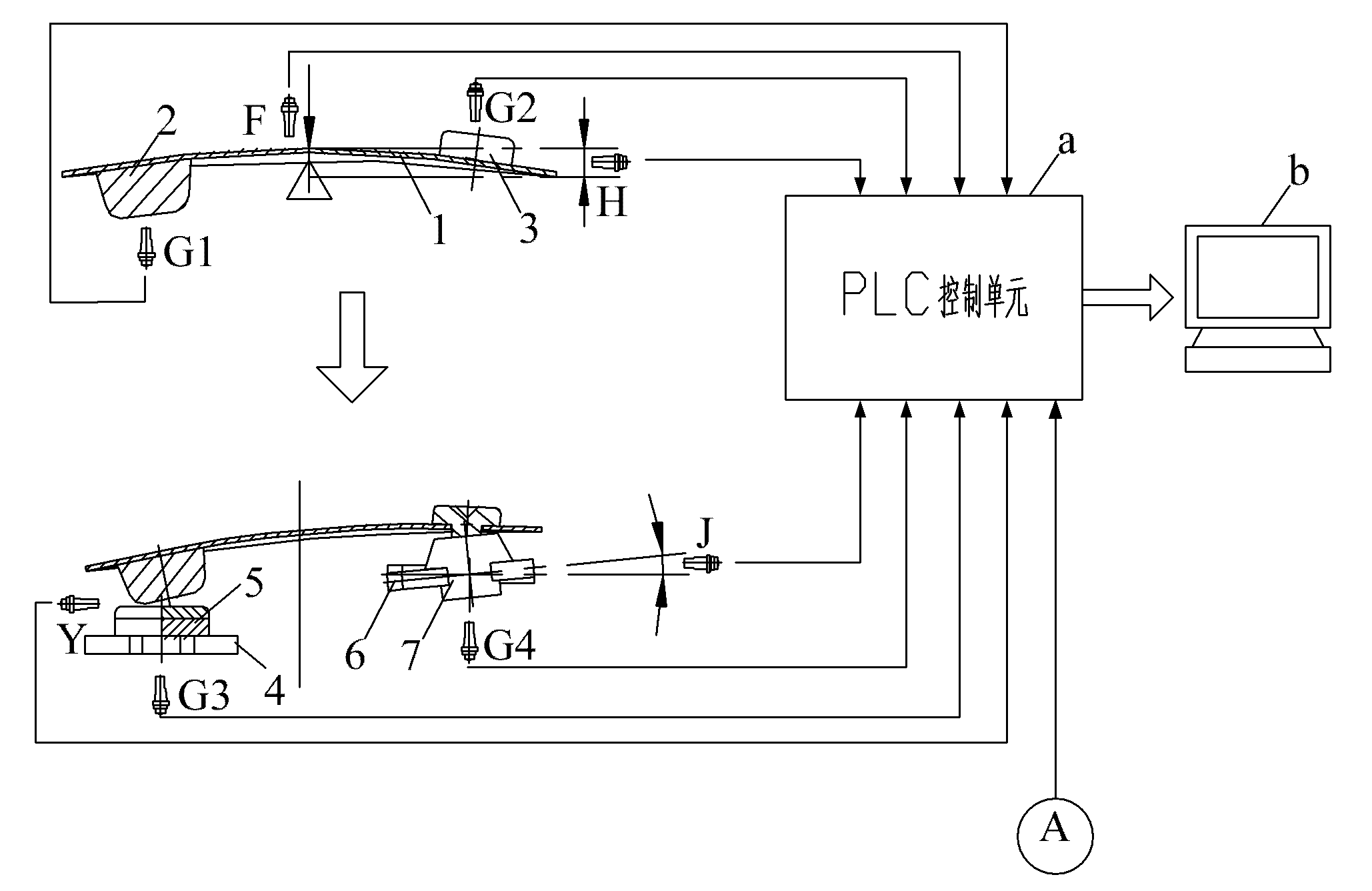

[0043] Specific implementation mode two: combination figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that it further includes an ammeter for monitoring the welding current and sending the welding current data to the PLC control unit a. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

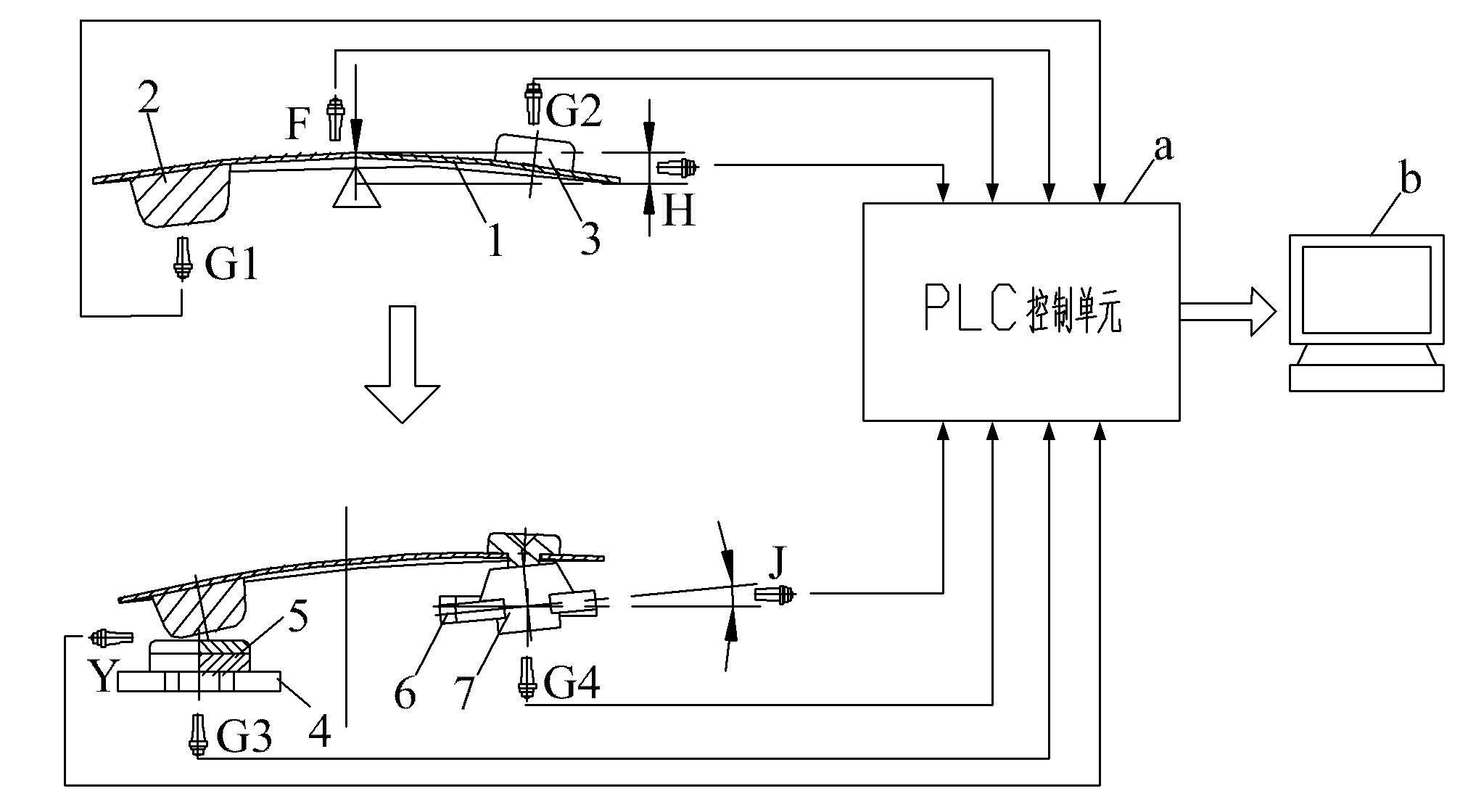

[0044]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the movable contact sensor G1, the rivet sensor G2, the static contact sensor G3, the welding chip sensor G4, the height sensor H and the angle sensor J adopt photoelectric switch sensors . E3S-GS15N photoelectric switch sensor manufactured for Yueqing Omron Sensor Factory. Pressure sensor F and preload sensor Y are SD-21R sensors produced by Yueqing Outer Electric Co., Ltd. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap