A preparing method of an antibacterial reverse osmosis membrane support body

A reverse osmosis membrane and support technology, which is applied in the field of antibacterial reverse osmosis membrane support preparation, can solve the problems of complicated operation and too simple production process, and achieve the effects of fast mixing, increased mixing range and high batching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the antibacterial reverse osmosis membrane support body comprises the following steps:

[0049] a. Weaving: Use polyester long fibers to weave into gray cloth on a warp knitting machine;

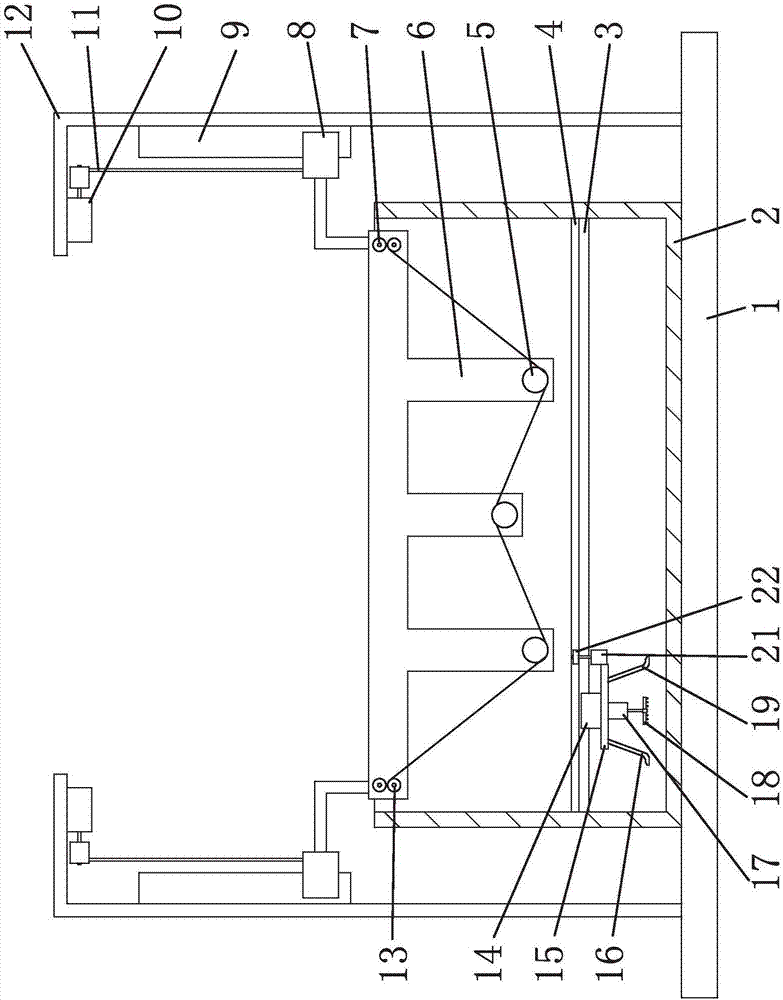

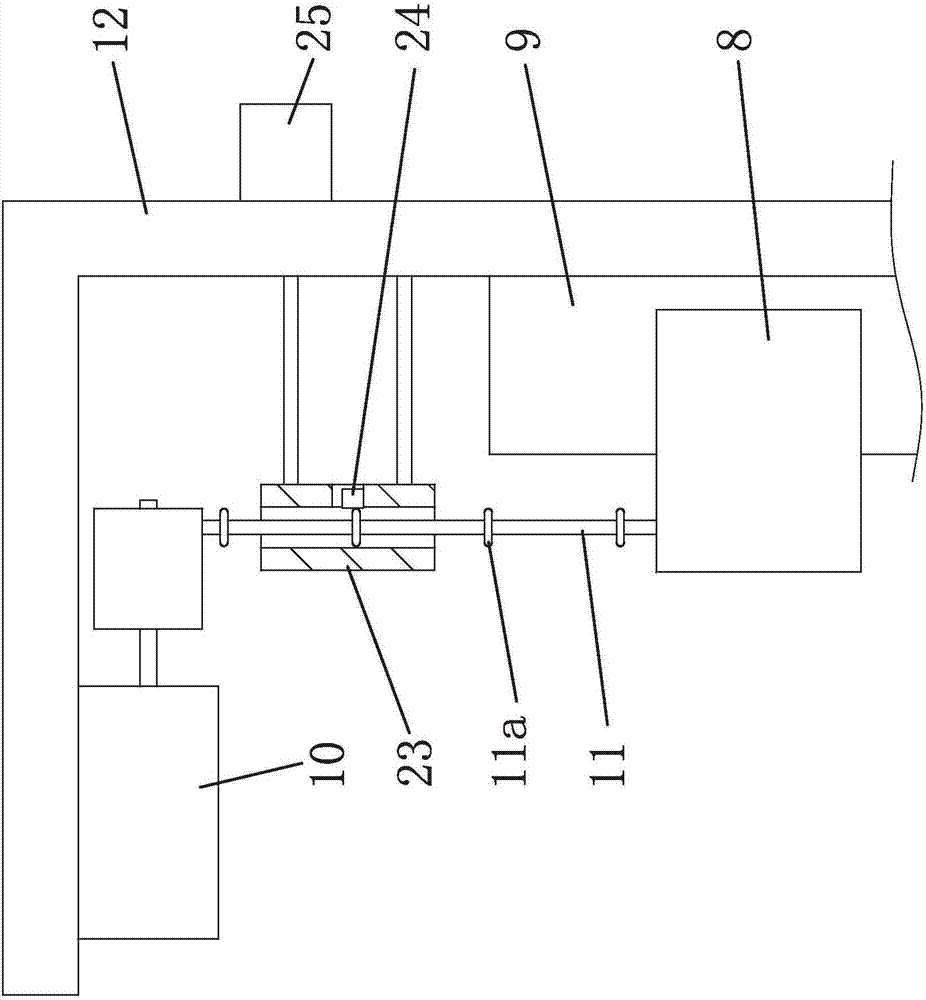

[0050] b. Shaping: Carry out high-temperature shaping to the gray cloth through a shaping device, the shaping temperature is 160-200°C, and the speed is 20-26m / min; in this embodiment, the shaping temperature is 180°C, and the speed is 24m / min;

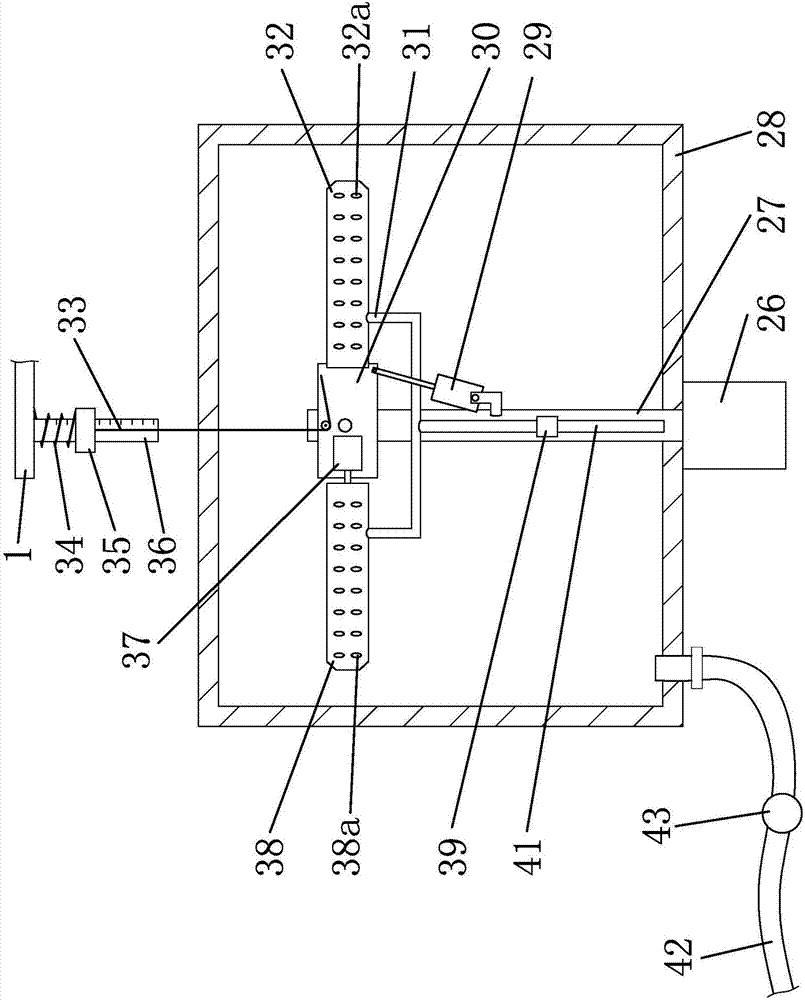

[0051] c. Padding finishing liquid: make finishing liquid, arrange the shaped embryos in the padding device for padding finishing liquid;

[0052] d. Finishing: first pre-bake the padded gray cloth at a temperature of 95-105°C for 5-8min, then bake at a temperature of 110-118°C for 3-8min, then wash with water, and finally dry to obtain antibacterial Reverse osmosis membrane support body: In this embodiment, firstly, the padded gray cloth is prebaked at a temperature of 100° C. for 6 minutes, and then baked at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com