A device for simulating the initial solidification of molten steel in a mold

A mold and molten steel technology is applied in the field of simulating the initial solidification device of molten steel in the mold, which can solve the problems of difficult meniscus area, deterioration of product quality, subcutaneous inclusions, etc., to achieve reasonable process parameters and reduce quality defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

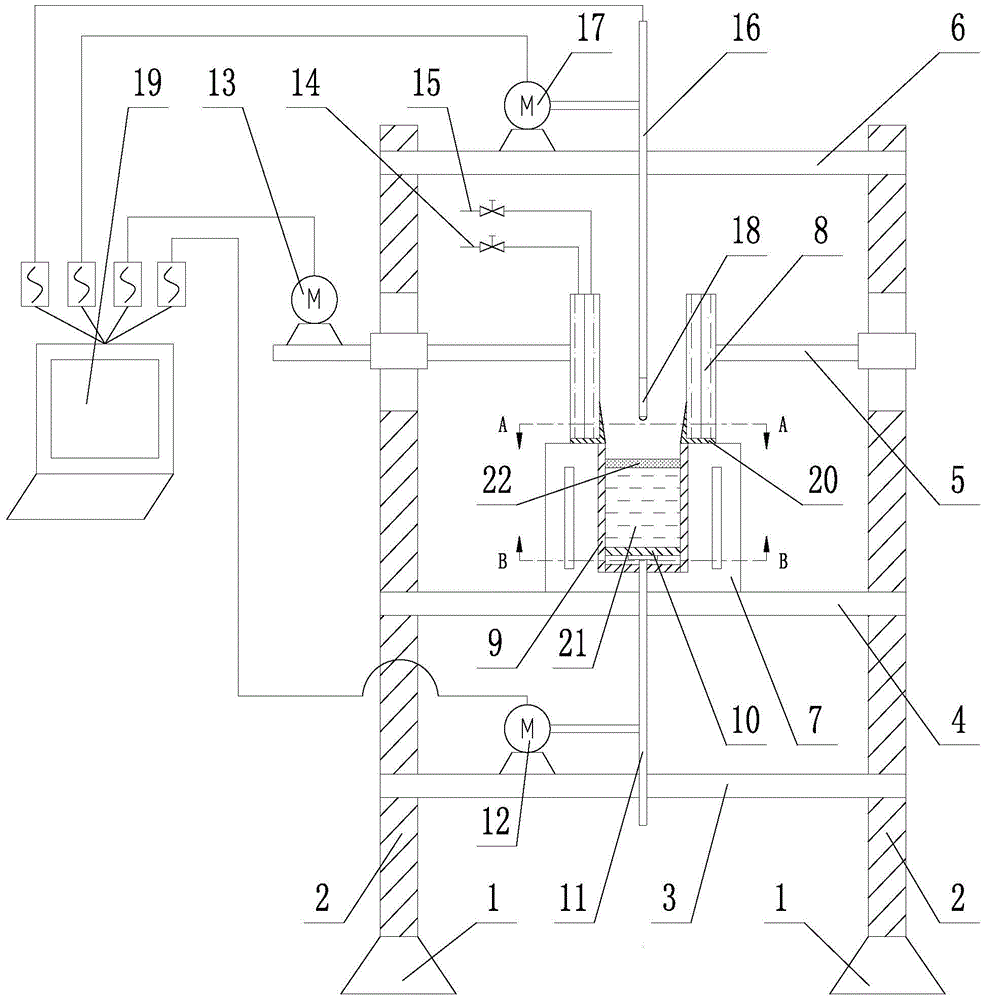

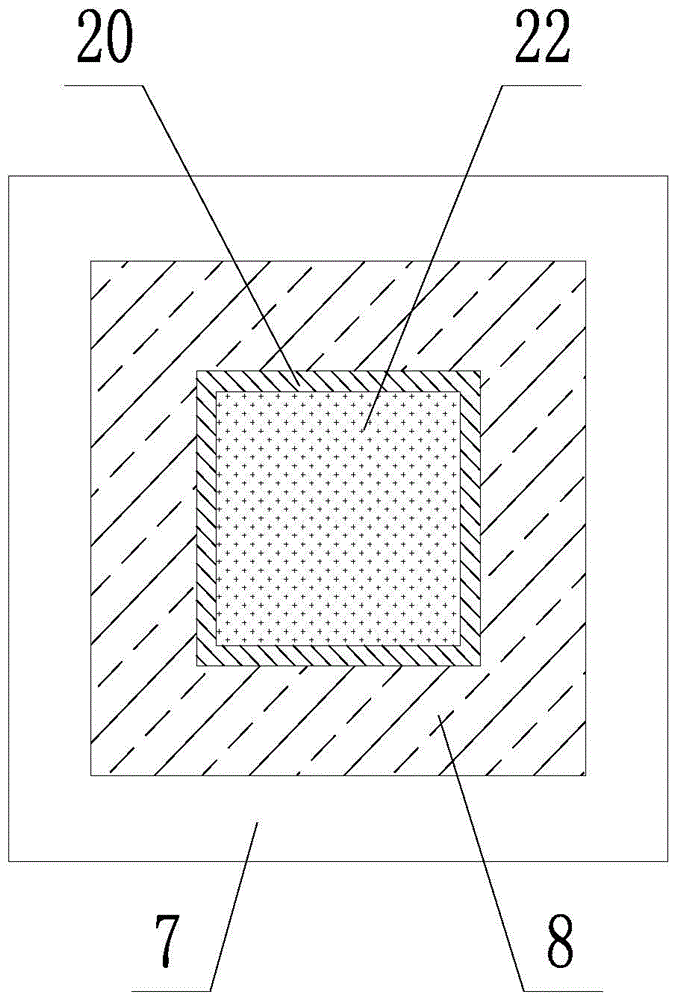

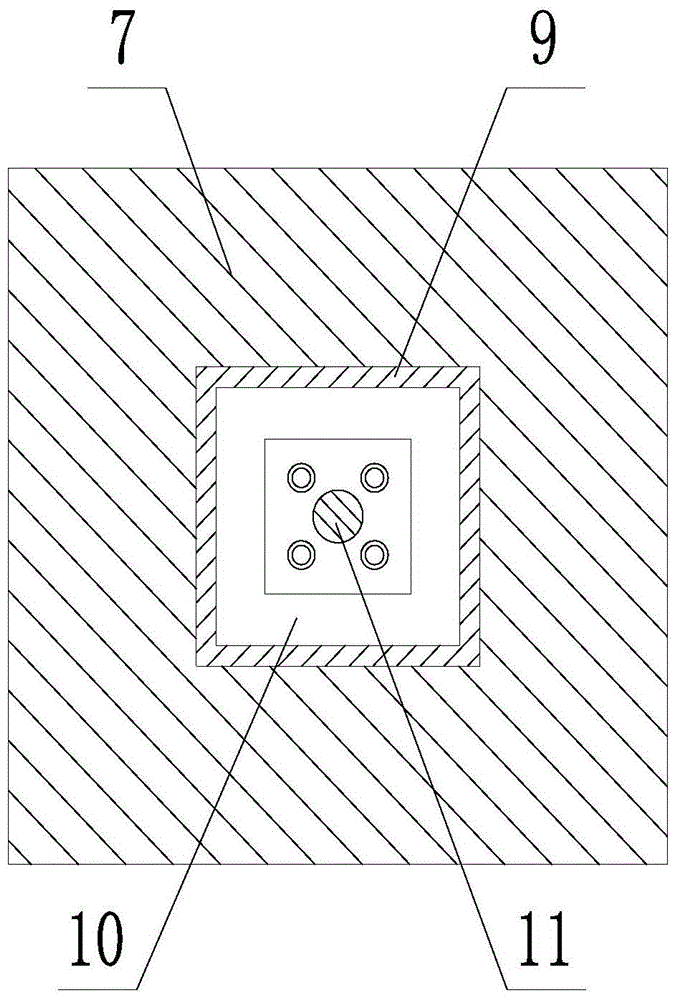

[0020] Such as figure 1 , 2 , 3, a device for simulating the initial solidification of molten steel in a crystallizer, including a base 1, a wall 2, a first stage 3, a second stage 4, a third stage 5, a fourth stage Object stage 6, heating electric furnace 7 and water-cooled crystallizer 8, described body of wall 2 is vertically arranged on the base 1, described first object stage 3, second object stage 4, third object stage 5, The fourth stage 6 is installed on the wall 2 sequentially from bottom to top; the electric heating furnace 7 is installed on the second stage 4, and the inner surface of the electric heating furnace 7 is covered with a detachable refractory material layer 9, which is fire-resistant Inside the material layer 9 is a molten steel cavity, and a refractory material baffle 10 is arranged at the bottom of the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com