Coagulated yoghurt with aloe fruit granules and manufacturing method thereof

A manufacturing method and technology of aloe vera fruit granules, applied in dairy products, food preparation, milk preparations, etc., to achieve good taste and flavor, enhance the taste of fruit granules, and have a good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

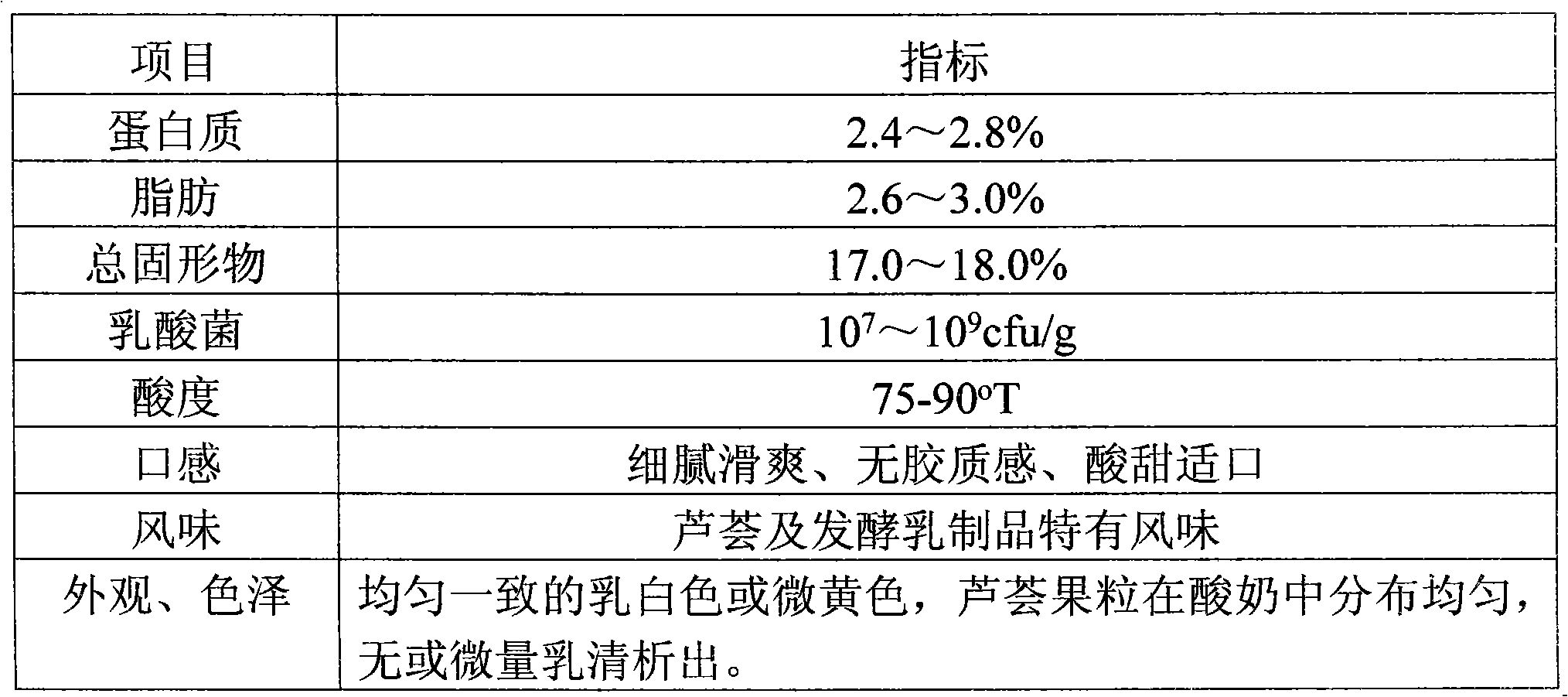

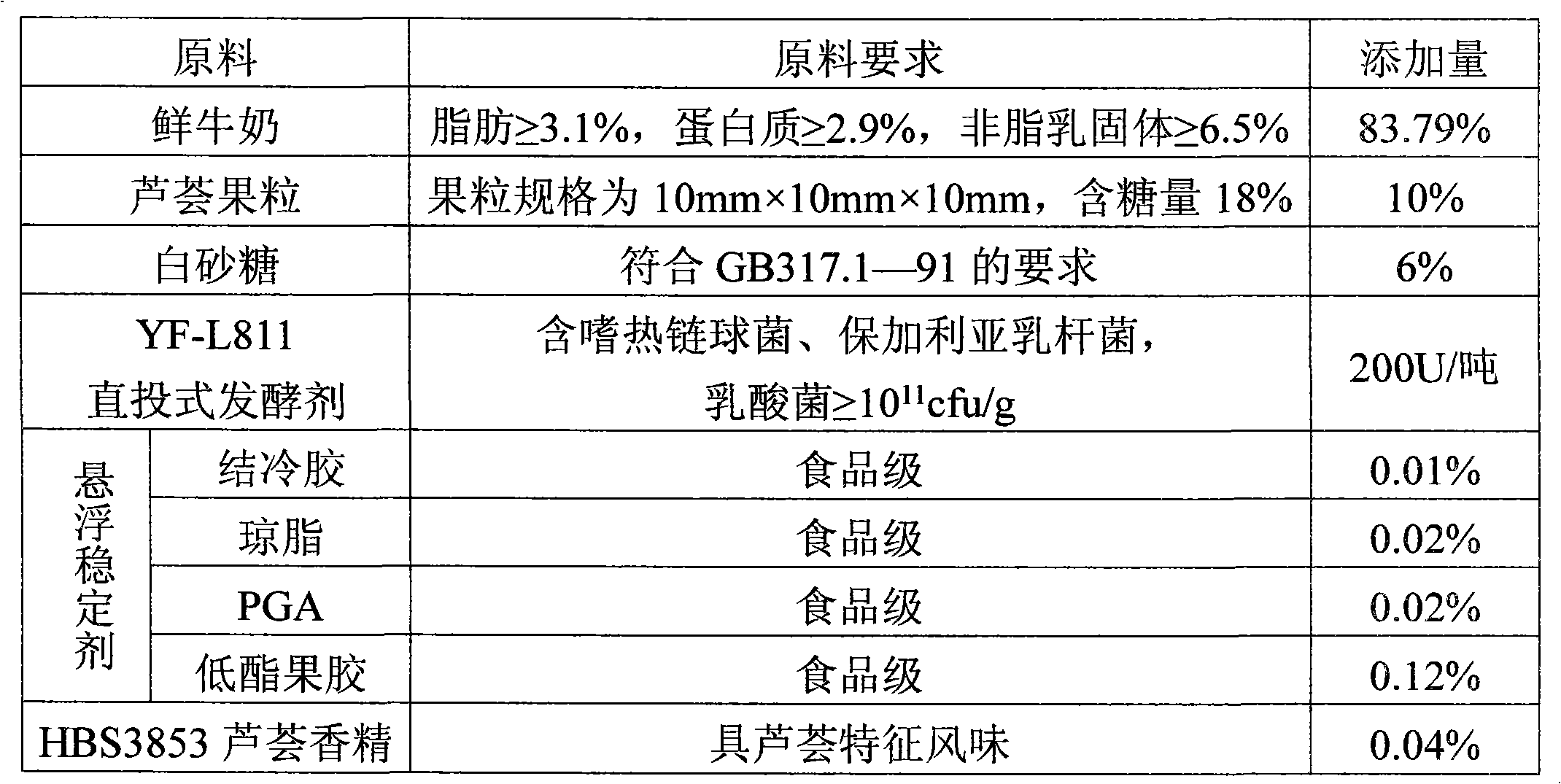

[0038] product ingredients

[0039]

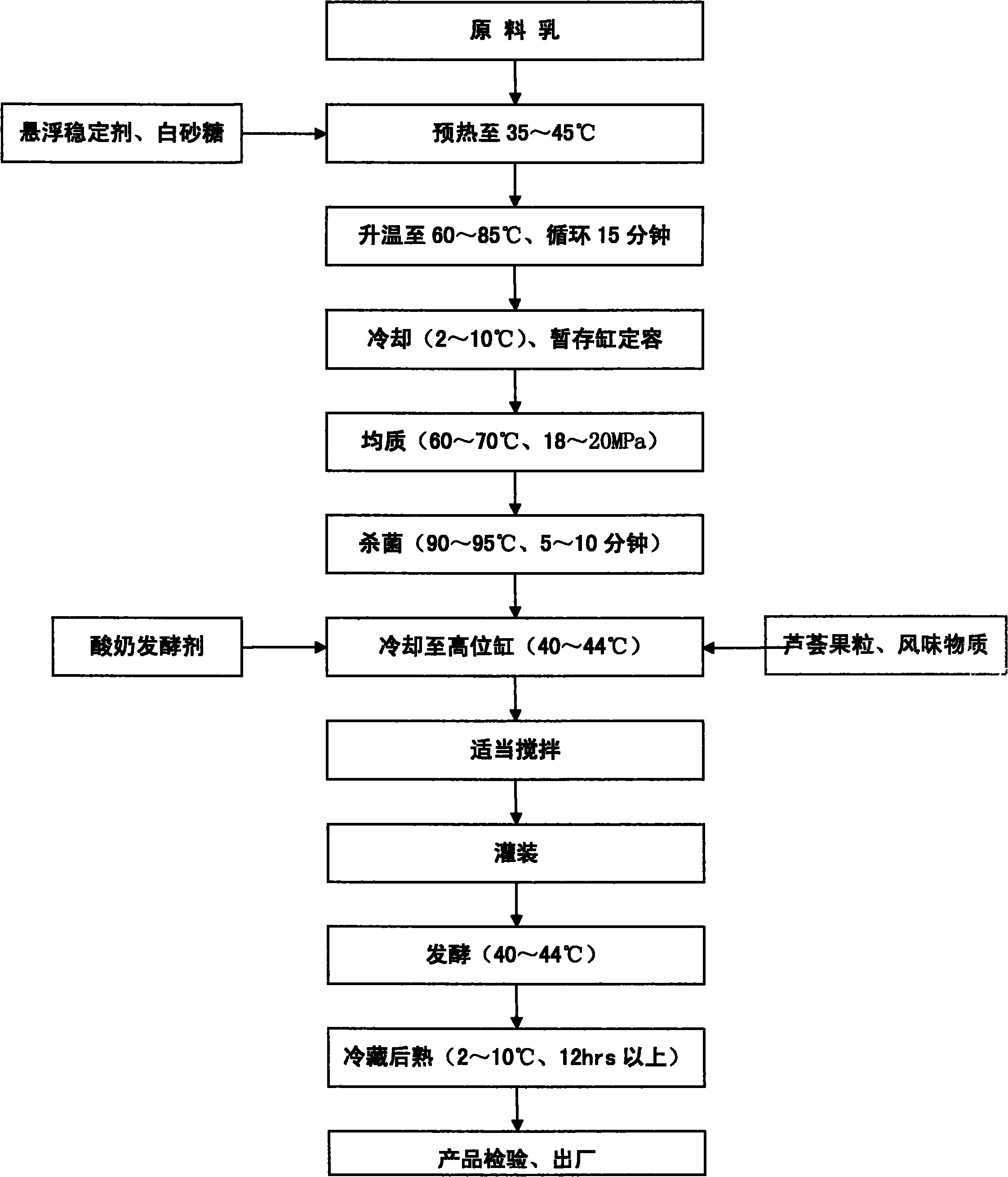

[0040] Prepare coagulated aloe fruit yogurt according to the product formula given in the above table. The preparation process is as follows:

[0041] (1) Raw milk pretreatment and ingredients: After centrifugation or filtration, the raw milk is heated to 40°C, added with white sugar and stabilizer through a water powder mixer, and then heated to 85°C for about 15 minutes and then passed through the cooling plate Store cooled to 5℃;

[0042] (2) Homogenization and sterilization: the above-mentioned material liquid is homogenized at 65°C and 20MPa, then sterilized at 95°C for 5 minutes, and then cooled to 42°C by cooling plates;

[0043] (3) Adding starter and fruit particles: Add starter, aloe fruit particles, and flavor substances to the material liquid after sterilization and cooling, and stir appropriately to make the starter and fruit particles evenly dispersed;

[0044] (4) Filling and fermentation: the material liquid added with starter and f...

Embodiment 2

[0047] product ingredients

[0048]

[0049] Prepare coagulated aloe fruit yogurt according to the product formula given in the above table. The preparation process is as follows:

[0050] (1) Raw milk pretreatment and ingredients: After centrifugation or filtration, the raw milk is heated to 40°C, added with white sugar and stabilizer through a water powder mixer, and then heated to 80°C for about 15 minutes and then passed through the cooling plate Cool to 2℃ and store;

[0051] (2) Homogenization and sterilization: the above-mentioned material liquid is homogenized at 70°C and 18MPa, then sterilized at 90°C for 10 minutes and then cooled to 42°C by cooling plates;

[0052] (3) Adding starter and fruit particles: Add proper amount of starter, aloe fruit particles, and flavor substances to the material liquid after sterilization and cooling, and stir appropriately to make the starter and fruit particles evenly dispersed;

[0053] (4) Filling and fermentation: the material liquid added...

Embodiment 3

[0056] product ingredients

[0057]

[0058] Prepare coagulated aloe fruit yogurt according to the product formula given in the above table. The preparation process is as follows:

[0059] (1) Raw milk pretreatment and ingredients: After centrifugation or filtration, the raw milk is heated to 35°C, white sugar and stabilizer are added through a water powder mixer, and the temperature is raised to 70°C for 15 minutes and then cooled by cooling plates Store at 2°C;

[0060] (2) Homogenization and sterilization: the above-mentioned material liquid is homogenized at 65°C and 20MPa, then sterilized at 95°C for 5 minutes, and then cooled to 42°C by cooling plates;

[0061] (3) Adding starter and fruit particles: Add proper amount of starter, aloe fruit particles, and flavor substances to the material liquid after sterilization and cooling, and stir appropriately to make the starter and fruit particles evenly dispersed;

[0062] (4) Filling and fermentation: the material liquid added with sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com