Multifunctional numerical control bending machine for molding irregular plates

A plate forming and irregular technology, which is applied in multi-functional irregular plate forming equipment and bending of irregular plates, can solve the problems that the processing of irregular plates can not be realized by numerical control and production automation, so as to reduce the labor intensity of workers and Effects of production cost, quality improvement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

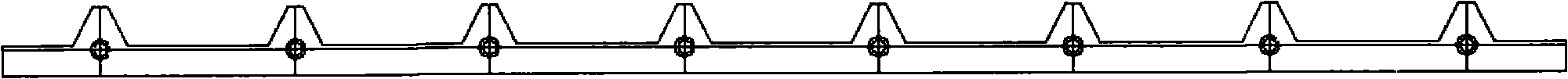

[0014] Take zigzag plate processing as an example.

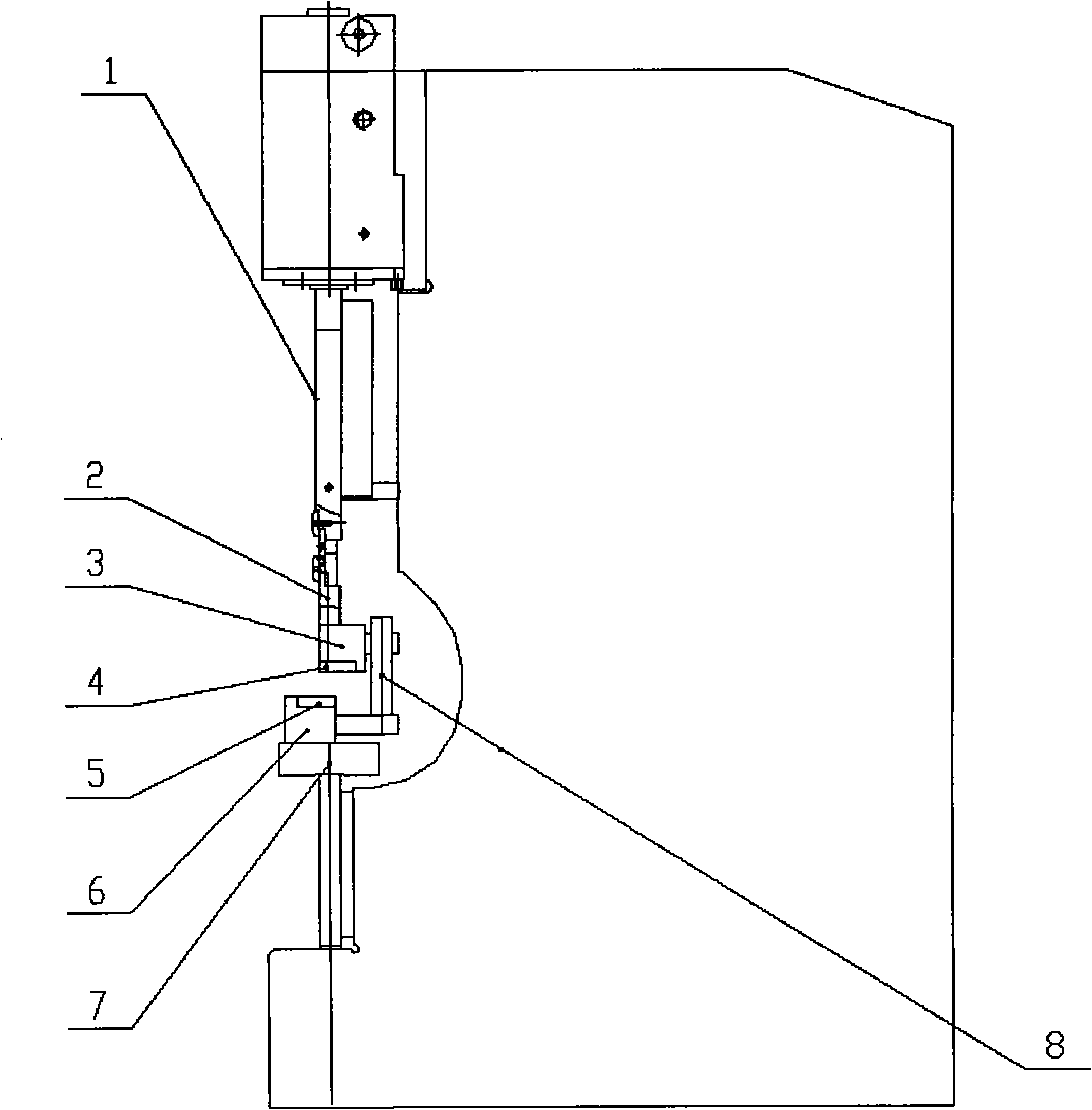

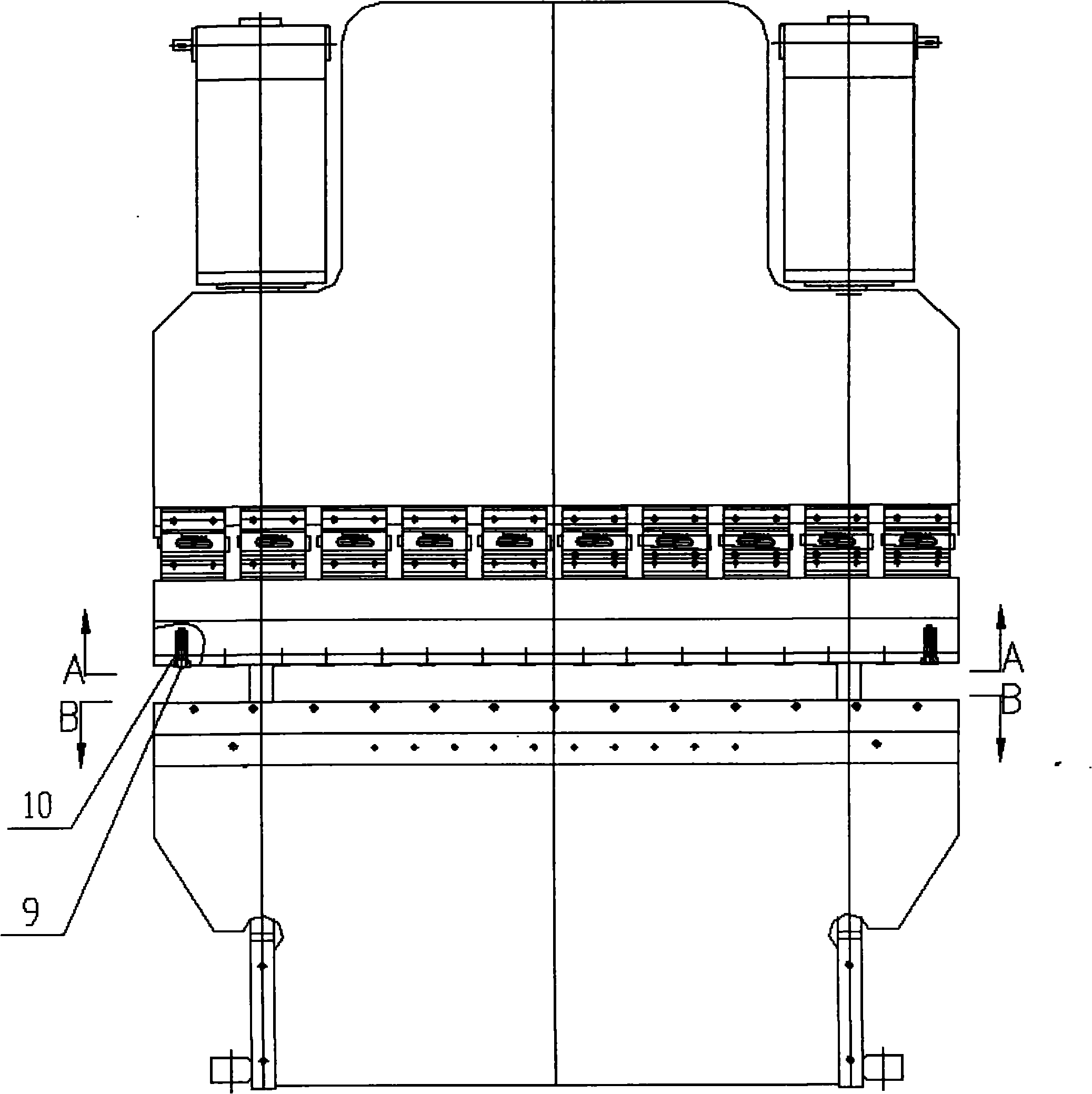

[0015] figure 1 , 2 , 3, 4 shown, a multifunctional irregular plate forming CNC bending machine. It mainly consists of a slider (1), a mold handle (2), an upper mold base (3), an upper blade (4), a lower blade (5), a lower mold base (6), a workbench (7), and a guide column (8 ), presser foot (9), spring (10), guide sleeve (11).

[0016] The device operates as follows:

[0017] (a) Put the workpiece (12) to be formed on the lower mold base (6), and the zigzag edge of the workpiece (12) is flush with the lower blade (5).

[0018] (b) Start the machine tool, the slider (1) moves downward, the upper mold base (3) and the lower mold base (6) move downward, and are guided by the guide post (8) and the guide sleeve (11), and are controlled by the numerical control system Set up your exercise schedule.

[0019] (c) The pressing material (9) contacts the workpiece (12) at first, and as the upper mold base (3) descends, the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com