Electro-pyrotechnic initiator and manufacturing method thereof

A technology of detonators and pyrotechnics, which can be used in blasting barrels, weapon accessories, vehicle parts, etc., and can solve problems such as poor leak-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

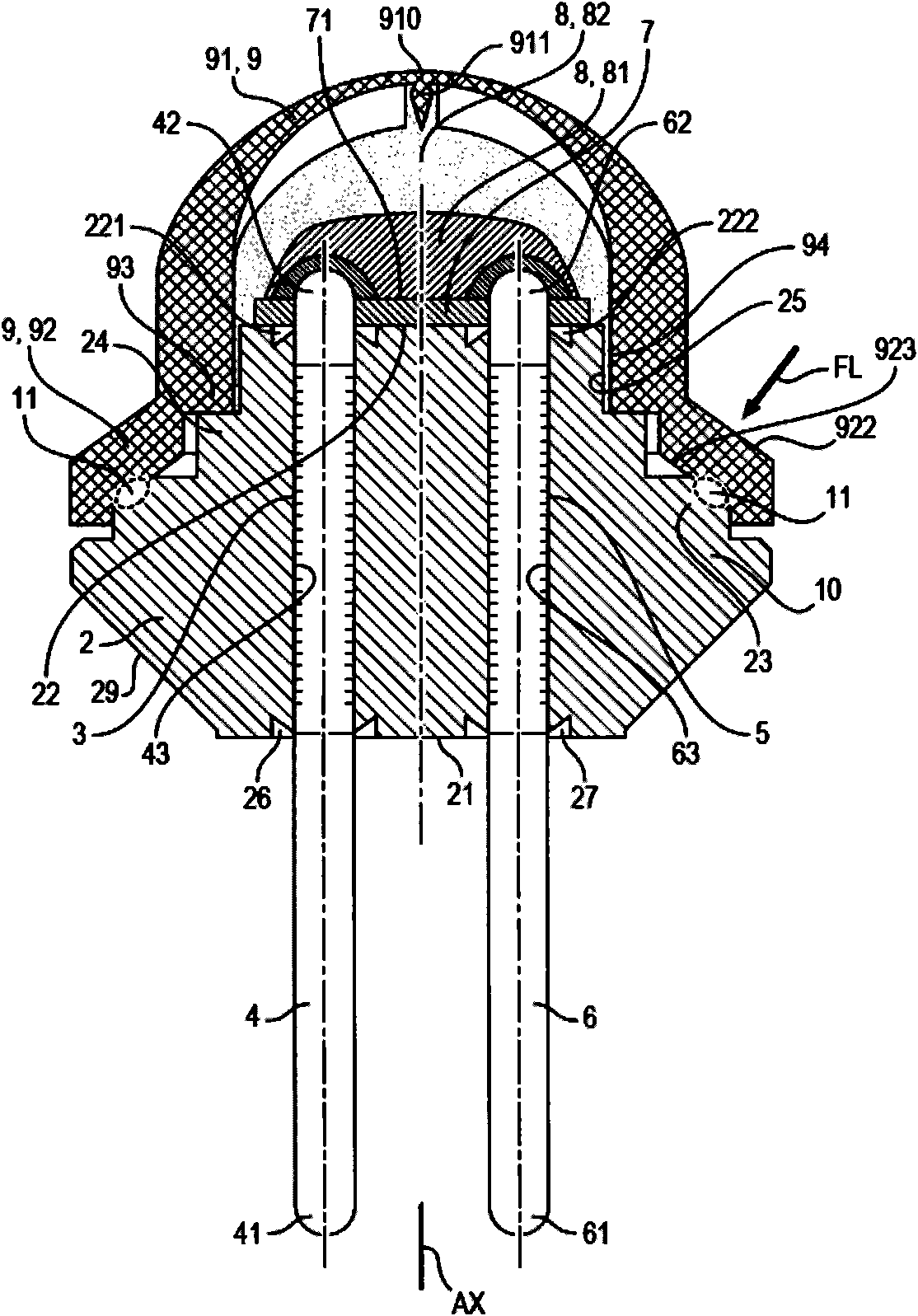

[0052] In the figures, the initiator 1 comprises a base 2 made of a first plastic material opaque to a laser beam having a defined wavelength. The base 2 comprises a first conduit 3 for insertion of a first electrode 4 and a second conduit 5 for insertion of a second electrode 6 . Pipeline 3 is different from Pipeline 5. Electrode 4 is different from electrode 6 . The electrodes 4 , 6 are electrically conductive and are, for example, metal. For example, the electrodes 4 , 6 are rectilinear and each formed by a metal pin, so that they can be cylindrical and have a circular cross section, for example.

[0053] The electrodes 4, 6 are inserted into the base 2 so that their respective first ends 41, 61 protrude from the first side 21 of the base 2 and their respective second ends 42, 62 protrude from the second side 22 of the base 2. protruding, the first end 41, 61 is used to connect to an external circuit for controlling the detonator, the second side 22 is different from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com