Method for drying and reducing low-grade latertic nickel ores by using bituminous coal

A lateritic nickel ore and low-grade technology, applied in the field of non-ferrous metals, can solve the problems of low thermal efficiency and achieve obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

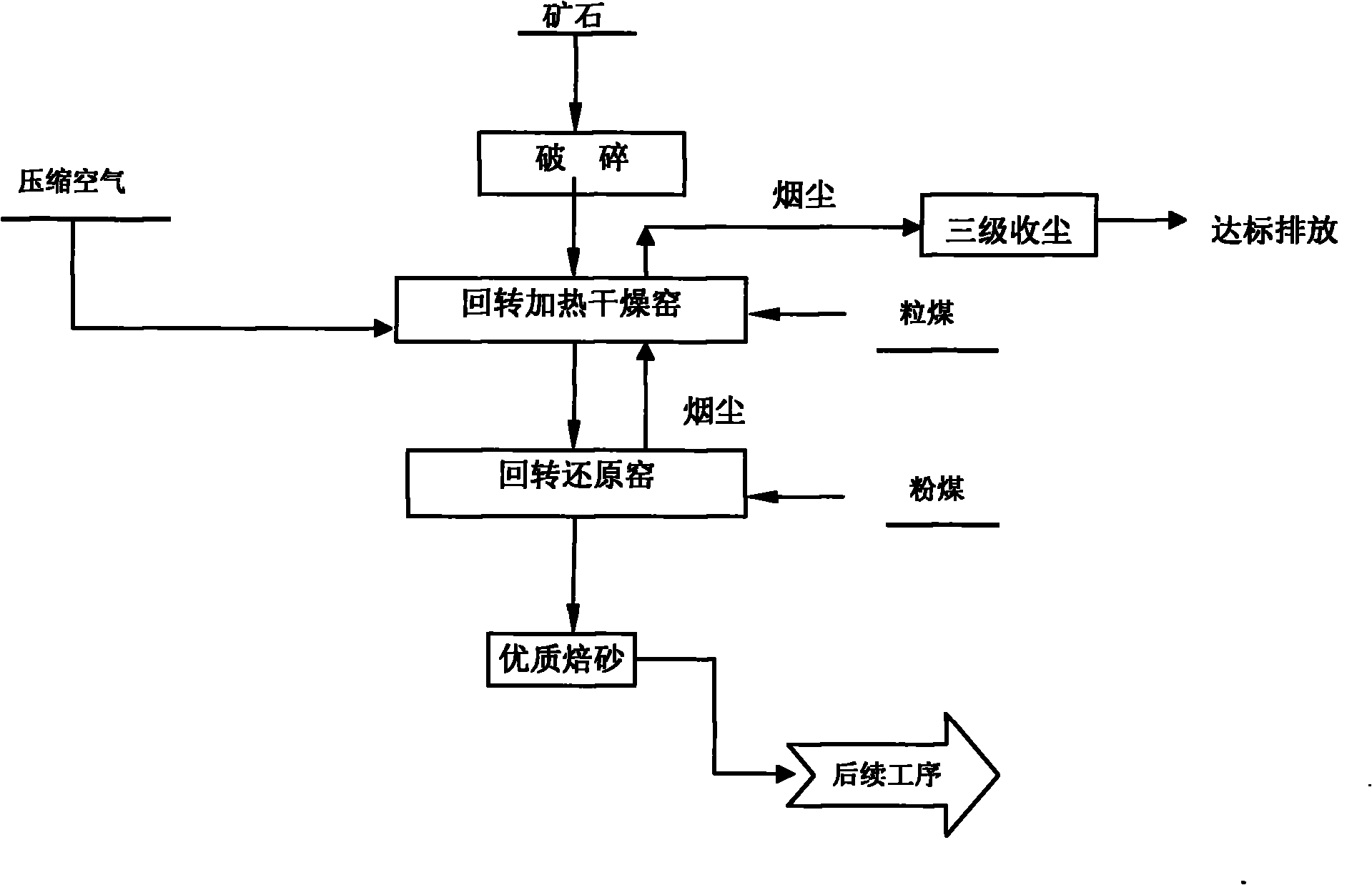

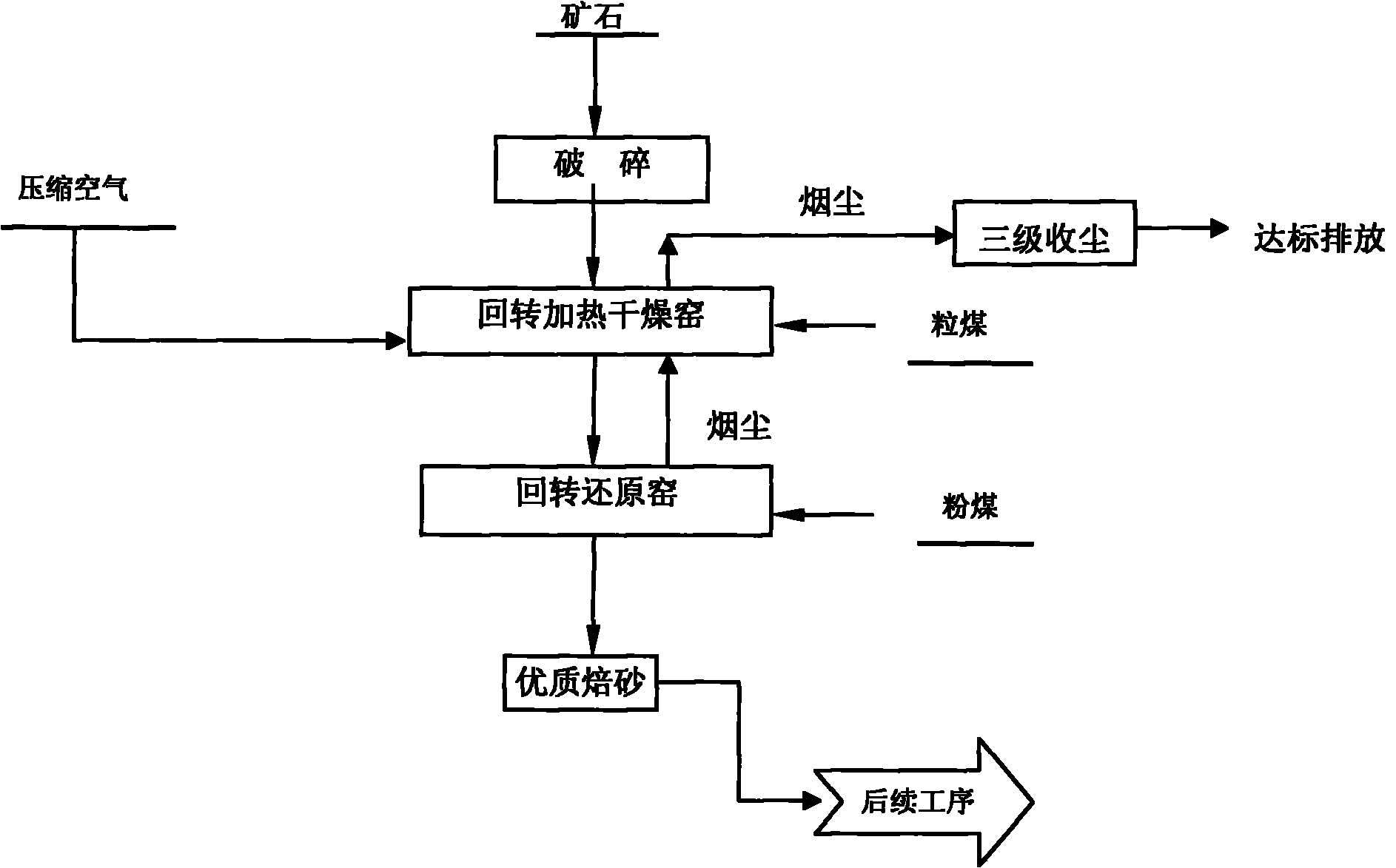

[0036] The invention adopts cheap and easy-to-obtain bituminous coal as a heat source and a reducing agent, and utilizes a two-stage kiln selective reduction technology of one-stage drying heating and one-stage reduction to realize efficient and selective reduction of nickel, cobalt and copper in laterite nickel ore, and realizes industrial application. The ferrous nickel laterite ore mined from the mine is first pre-screened, and the size of 3mm to 600mm is crushed in three stages and one closed circuit to less than 15mm, and then sent to the rotary kiln for reduction roasting. The dust less than 3mm is mixed with the dust collected by the dust collection system for granulation, and then sent to the rotary kiln for reduction roasting. Adopt a continuous airtight one-stage dry heating, one-stage reduction second-stage kiln, use coal as heat source and reducing agent (addition rate is 10%), and roast for 40-50min at a roasting temperature of 700-800°C in a reducing atmosphere to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com