Preparation method of labeled cellulose fibers

A technology of cellulose fiber and cellulose A, which is applied in the field of fiber, can solve the problems of high cost of instruments, achieve the effects of easy operation, accurate detection results, and qualitative and quantitative detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing marked cellulose fibers, comprising:

[0021] Provide a dispersion liquid, the dispersion liquid includes 0.01wt%-10wt% metal inorganic compound, 0.1wt%-0.5wt% dispersant and 89.5wt%-99.89wt% water, the metal inorganic compound is white or silver White;

[0022] Alkali cellulose is obtained by soaking, pressing and pulverizing the cellulose pulp;

[0023] After aging, yellowing, dissolving, mixing, defoaming, filtering and spinning the alkali cellulose, the labeled cellulose fiber is obtained. When the yellowing, dissolving, mixing or spinning is carried out, the The dispersion liquid is added to the material, and the metal-inorganic compound in the dispersion liquid is 0.001wt%-0.05wt% of the first cellulose in the material.

[0024] The present invention adds 0.01wt%-10wt% metal inorganic compound, 0.1wt%-0.5wt% dispersant and 89.5 Wt%~99.89wt% water dispersion liquid, obtain the marked cellulose fiber. According to th...

Embodiment 1

[0037] Commercially available magnesium oxide is crushed to particles with an average particle size of 1.9 microns;

[0038] 40g of the above-mentioned magnesium oxide particles, 26g of fatty alcohol polyoxyethylene phosphate and 9934g of water were uniformly mixed to obtain a dispersion;

[0039]Using hemp pulp as raw material, soaking, pressing and pulverizing it to obtain alkali cellulose; after aging and yellowing the alkali cellulose, adding the above dispersion liquid to solvent water, and then turning the yellow Thin cellulose xanthate drops into the described water that has added dispersion liquid and dissolves, and the magnesium oxide in the dispersion liquid accounts for 0.0015wt% of first-class cellulose; The cellulose xanthate through dissolving is mixed, defoamed and Filtration treatment to obtain a spinning glue solution; spinning the spinning glue solution to obtain marked cellulose fibers.

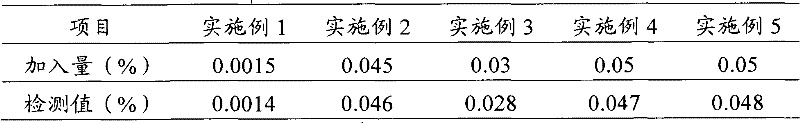

[0040] The marked cellulose fibers were detected with an atomic absor...

Embodiment 2

[0042] Commercially available titanium oxide is crushed to particles with an average particle size of 0.45 microns;

[0043] 28g of the above-mentioned titanium oxide particles, 1.5g of sodium hexametaphosphate and 996.5g of water were uniformly mixed to obtain a dispersion;

[0044] Cotton pulp is used as a raw material, and alkali cellulose is obtained after soaking, pressing and pulverizing; viscose is obtained after the alkali cellulose is aged, yellowed, and dissolved, and the viscose is added to the viscose during the mixing process. Add the above-mentioned dispersion liquid in the glue, the titanium oxide in the dispersion liquid accounts for 0.045wt% of the first cellulose in the viscose; the viscose after the mixing treatment is degassed and filtered to obtain the spinning dope; The sericin solution is spun to obtain the marked cellulose fiber.

[0045] The marked cellulose fibers were detected with a visible light spectrophotometer, and the results are shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com