Multistage compressor and oscillating piston

A technology for swinging pistons and compressors, applied to pistons, multi-stage pumps, cylindrical pistons, etc., can solve the problems that it is difficult to fully prevent the deformation of lip rings, and achieve the effect of small resistance and improved assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

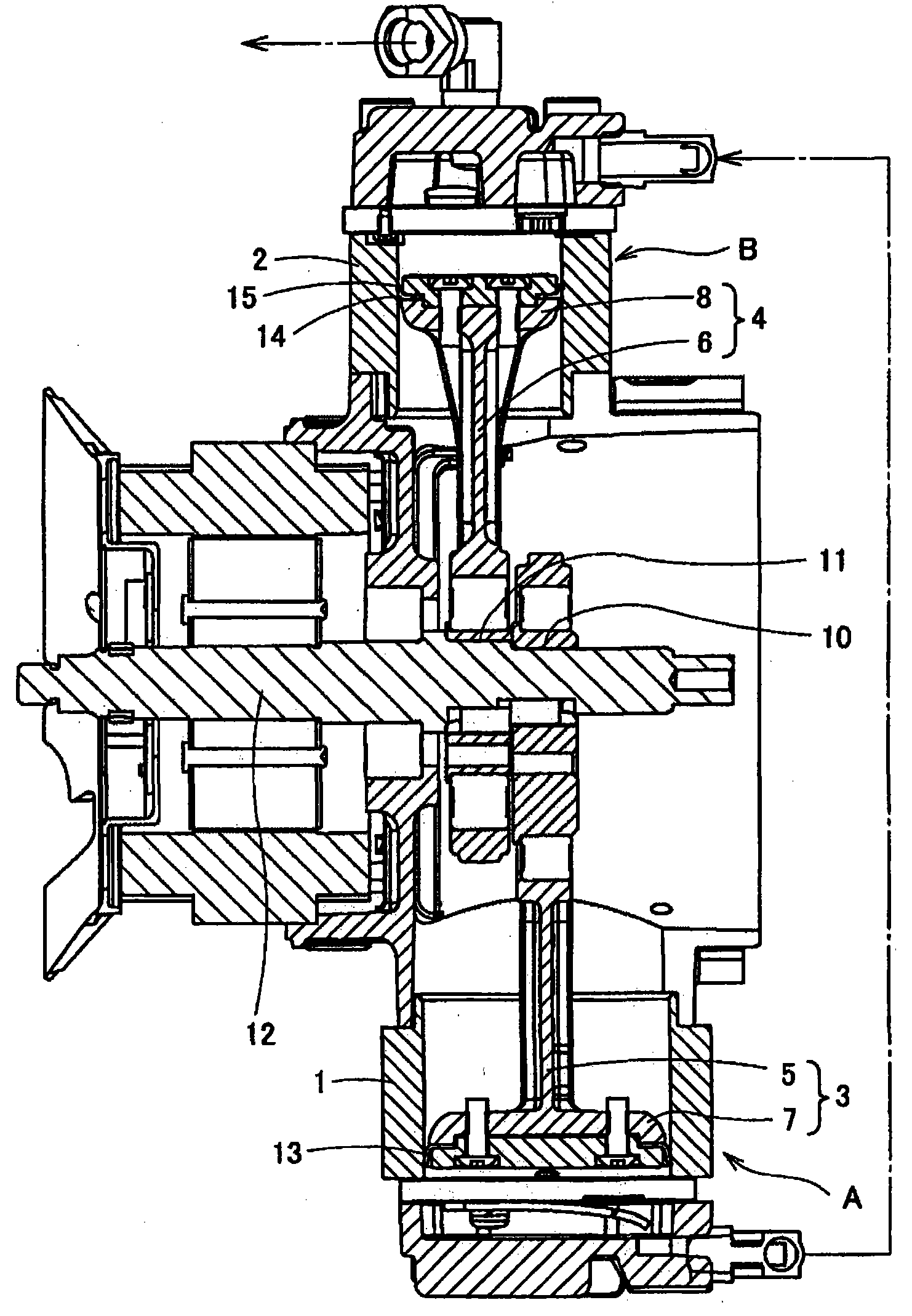

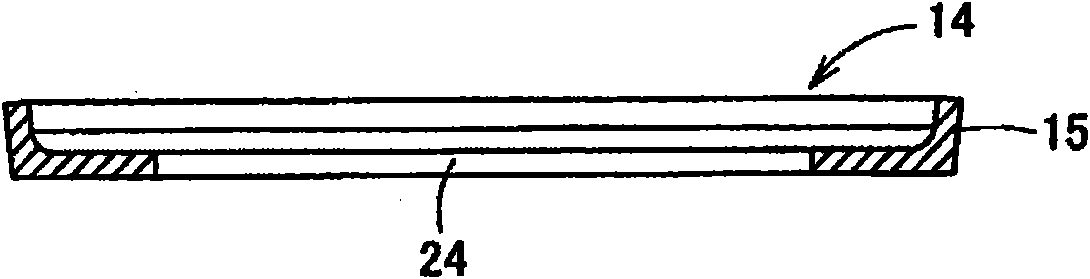

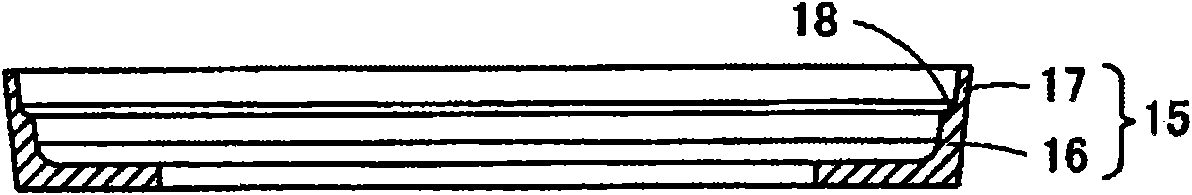

[0065] figure 1 Indicates a multi-stage (two-stage) compressor. This multi-stage compressor is formed by connecting a low-pressure compressor A and a high-pressure compressor B, and swing pistons 3 and 4 are housed in cylinders 1 and 2 of the compressors A and B so as to be able to swing and slide freely. In each of the swing pistons 3, 4, disc-shaped piston portions 7, 8 are integrally provided at the front ends (small end portions) of the connecting rods 5, 6. As shown in FIG. A crankshaft 12 disposed at the center of the device main body is supported by bearing holes 10 and 11 formed at eccentric positions of bases (big ends) of the connecting rods 5 and 6 . The crankshaft 12 is operationally connected by an unillustrated rotary drive device.

[0066] In the above-mentioned compressors A and B, the swing piston 3 of the compressor A on the low-pressure side (primary pressure) side reciprocates due to the rotation of the crankshaft 12, and the atmospheric air taken into th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap